Introduce

2 way Solenoid valve is a key component widely used in situations where automatic fluid control is required. Guided by external electromagnetic signals, it directly controls the fluid medium,It has the advantages of simple structure, rapid response, and precise control. In fields such as water treatment, healthcare, food, and chemical engineering,electric 2 way valve often holds an irreplaceable and important position.

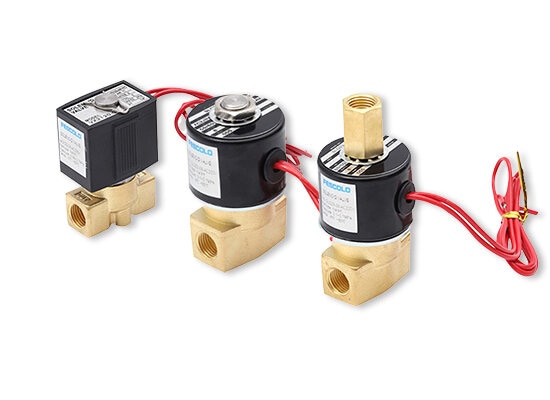

What is a 2 way Solenoid valve

A valve 2 way,we all know that it has two ways are respectively one Inlet Port and one Outlet Port.So what is a 3 2 way solenoid valve? We all know that it is also a kind of using Electromagnetic drive,It has 3 ports and 2 working positions, The 3/2 soleoid valve has an additional port compared to the 2-way soleoid valve.

Similarly,electric 2 way valve has a simpler structure,It makes its installation very flexible, and its simple structure also makes its cost very low.The 3 position 2 way solenoid valve, due to its complex structure, is mainly used for media flow path switching and actuator control.2-way solenoid valve is very well-suited for use as on/off valves for liquid or gas media, It often proves to be highly effective in industries such as water treatment, food and beverage, medical equipment, household appliances, and chemical processing.

The function of 2 way solenoid valve

Solenoid valve 2 way has two ports—an inlet and an outlet—and operates by energizing or de-energizing the solenoid coil to open or close the valve, allowing or blocking gases or liquids.

Opening and closing flow paths: Quickly switches the valve to start or stop fluid flow.

Automation control: Works with electrical control systems for remote and automated fluid management, enhancing system efficiency.

Safety shutoff: Provides rapid shutoff of gas or liquid in emergency situations to protect equipment and personnel.

Energy efficiency and precise control: Controls flow accurately to minimize waste and improve process stability.

A 2 way electrical solenoid valve is the most basic type of solenoid valve, used primarily to control the start and stop of fluid flow.It can be used in conjunction with external system components to meet safety, energy-saving, and automation requirements.

The types of 2 way solenoid valve

Classified by working methods

Direct acting 2 way solenoid valve

The valve core is directly driven by an electromagnet, with a simple structure and suitable for low flow and low pressure drop applications.

Pilot operated 2 way solenoid valve

Using a smaller electromagnetic force to control the main valve core through the pilot port is suitable for systems with larger flow rates and higher pressures.

Classified by work status

Normally Closed

When the valve is powered off, it closes; when powered on, it opens the air circuit.

Normally Open

When the valve is powered off, it opens; when powered on, it closes the gas path.

Additionally, electromagnetics valve 2 way can also be classified based on sealing materials, connection types, application fields, and other aspects.

The advantages of 2 way Solenoid valve

◆ Simple structure, small size, easy installation

◆ Quick response and short opening and closing time

◆ Good sealing and low leakage rate

◆ Accurate control, suitable for fluid on/off control

◆ Low energy consumption, energy-saving and environmentally friendly

Features of 2 way solenoid valve

solenoid valve 2 way has very simple and clear on/off control:There is only one import and one export,Implement switch type control either current flow or cutoff,Clear structural logic and reliable control

◆ Electromagnetic drive, fast response:Control the valve core action through electromagnetic coils,Immediate action upon power on, reset immediately upon power ofThe response time is usually within a few tens of milliseconds

◆ Compact structure and easy installation:Integrated small volume design,Suitable for installation in devices with limited space,Easy maintenance and replacement

◆ Widely applicable media:Can control various fluids such as gas, liquid, steam, oil, etc,The valve body is made of various materials to meet different corrosive requirements

◆ Multiple control methods:Commonly known as normally closed type,There are also normally open types Applicable to different security strategies

◆ Strong electrical compatibility:Diverse driving voltages,Easy to integrate into PLC, relays, and automation control systems

2 way solenoid valve application

Building automation:control water heating system, solenoid valve, air conditioning water circuit

food/beverage industry:Precise control of filling and cleaning fluid channels

Medical equipment:controls the flow of gas, water, and medication to ensure clean and controllable fluid pathways

Chemical industry:Automatic control of corrosive or special liquids

The working principle of 2 way solenoid valve

The key components Of electrical valve 2 way include Coil (Electromagnet),Plunger or Armature,Spring,Valve Body with Inlet/Outlet.

working principle

A 2-way solenoid valve uses an electromagnetic coil to open or close a flow path between two ports, providing directly on/off control of fluids in automated systems.

Power requirements

Advantages of DC power supply: fast response, small coil temperature rise, no electromagnetic noise; Advantages of AC power supply: No rectification required, convenient for long-distance transmission, but with higher electromagnetic noise.

2 way solenoid valve typically operates at DC 12V or AC 110V. 3-way solenoid valves generally have higher power requirements and commonly use DC 24V or AC 220V. Pneumatic solenoid valves come in various configurations, with DC 24V, AC 110V, or AC 220V being the most commonly used voltages.

3 way vs 2 way solenoid valve

2 Way Solenoid Valve:

Has two ports (inlet and outlet) and controls the flow by either allowing fluid to pass through or blocking it.Electromagnetism valve 2 way operates as a simple on/off valve, suitable for start/stop control of liquids or gases.

3 Way Solenoid Valve:

Has three ports and can direct the flow from one port to another or vent it to the atmosphere. It is typically used to switch between two different flow paths or to control the flow and exhaust in pneumatic systems.A 3-way solenoid valve not only controls the on/off flow of a fluid medium, but also enables switching or directional control, making it more suitable for use in automated control systems. A single 3-way valve can replace the function of multiple 2 solenoid valve.

Overall, a 3 way solenoid valve is more versatile than a 2 way electric valve, capable of handling more complex operating conditions such as path switching, exhaust, and connecting or disconnecting multiple fluid lines. It is an ideal component for advanced automated control systems.

We offer valve 2way with industrial art. Contact us directly for the latest electric valve price and product catalogue. We also have 3-way, 4-way, 5-way and other port types for more complex fluid or pneumatic control scenarios, especially indispensable in automation and pneumatic systems.