What is a diaphragm valve?

A diaphragm Valve is a type of mechanical valve that controls the on-off flow of fluids by the Vertical up and down movement of a flexible elastomeric diaphragm. Therefore, it is also known as liner motion diaphragm Valve that has various external driving modes available, including manual, electric, pneumatic, hydraulic, etc.

The diaphragm valve'diaphragm is the complete isolation of the fluids from the actuator and upper mechanical components, ensuring a clean and corrosion-resistant operating environment for them. Diaphragm control valve offers functions such as flow shut-off and regulation, effective sealing and isolation, and strong resistance to corrosion and contamination.

Structurally, Diaphragm control valve consists of a valve body, an elastic diaphragm, and an actuator. Under pressure, the diaphragm presses against or lifts from the valve seat to open or close the flow path. The valve membrane itself is smooth and elastic and can play a safe isolation function, coupled with a smooth valve cavity is especially suitable for industries with strict hygienic or anti-corrosion requirements—such as pharmaceuticals, biotechnology, food and beverage, chemical processing, and water treatment—especially where fluids may contain solid particles.

Six Key features of diaphragm valve

Compared to other types of mechanical valves, diaphragm valve can be remotely and automatically actuated. In addition, it also has other features that we will discuss in detail.

◆ Component Protection: The most notable feature of the diaphragm valve is that it can isolate the fluid from the mechanical parts, thereby preventing damage to the important components.

◆ Preventing leaks: Another feature of the diaphragm valve is its leak-proof design; the diaphragm can tightly seal against the valve seat, eliminating any potential air trap paths that could lead to media leakage.

◆ Precise Flow Control: Whether pneumatic, electric, or manual, diaphragm valves can all regulate the flow of fluid media.

◆ Corrosion Resistance: The diaphragms are made of durable materials such as polytetrafluoroethylene (PTFE) and is not easily corroded by chemical media.

◆ Compact Design: Manual diaphragm valves is their compact design, making them suitable for applications with limited space.

◆ Low Maintenance: Diaphragm valves have a simple structure, requiring inspection and maintenance primarily on the diaphragm, valve seat, and connections.

The different functions of a diaphragm valve

The primary function of a diaphragm control valve diaphragm is to control the flow of fluids in a system by using a flexible diaphragm which can achieve leak prevention while ensuring tight closure and precise flow control.

Flow On/Off Control:Opens or closes the flow path by raising or lowering a flexible diaphragm.

Flow Regulation:Allows for limited throttling or regulation of fluid flow in non-critical applications,but the flow control accuracy is not as good as that of ball valves or control valves.

Tight Sealing:The diaphragm is usually designed as a flexible thin sheet, with the central part fixed and the edges able to move freely. During opening and closing, it can effectively seal shut, fitting tightly against the valve seat to prevent contamination leakage, ensuring the safety of equipment and personnel.

Media Isolation:The diaphragm of the diaphragm valve is made of corrosion-resistant and chemically resistant materials and is positioned directly between the valve body and the valve bonnet, completely isolating the process fluid from the mechanical components and protecting parts such as the valve stem and actuator.

Corrosion and Contamination Resistance:Using inert materials and a smooth surface diaphragm path, suitable for ultra pure fluids.

While diaphragm valves can achieve both isolation and medium regulation functions, their regulation accuracy is significantly inferior compared to globe valves. Additionally, their adjustment speed is typically slower than that of ball valves and butterfly valves, and the fluid flow resistance is higher than that of gate valves and axial valves.

Read this article for a more detailed comparative analysis of valve characteristics.

Core advantages of diaphragm valve

Compared with other similar mechanical valves, flexible diaphragm valves have many advantages. Let's explore the main advantages of diaphragm valves.

◆ Versatility: Diaphragm valves are suitable for a wide range of applications, from simple flow control to complex fluid handling systems.

◆ Cost-Effective: With their durable construction and low maintenance requirements, diaphragm valves offer long-term value.

◆ Safety: The design of diaphragm valves ensures that fluids are contained securely, minimizing the risk of leaks and spills.

◆ Automation: When equipped with a pneumatic actuator, air diaphragm valves offer automated flow control, improving operational efficiency and reducing manual intervention.

Different types of Diaphragm Valve

◆ DM Series:This is a type of pneumatic diaphragm valve with two ports, driven by an air operated actuator to actuate the diaphragm up and down in a straight line. The valve body is made of stainless steel, the diaphragm is made of EPDM+PTFE composite material, the actuator housing is made of PPS material, and there is an O-ring and seal with a sealing structure.

How does a diaphragm valve work?

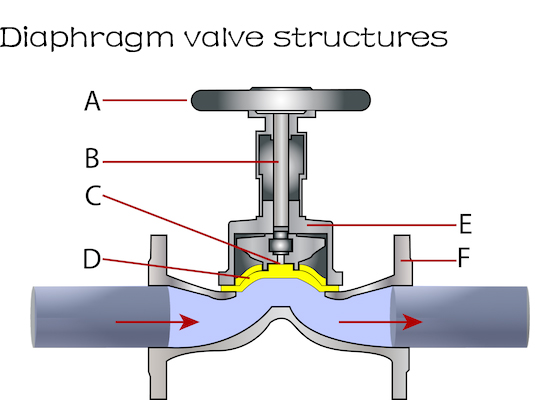

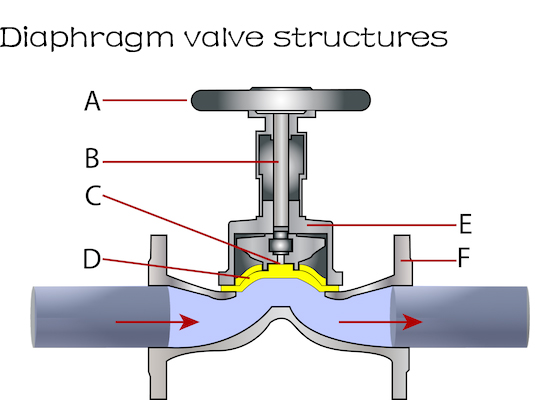

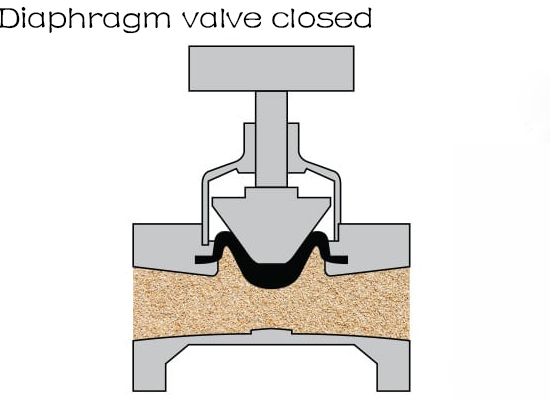

Though diaphragm valve has different actuation types,but is works mainly by using different methods to drive the valve stem to drive the elastomer membrane up and down.Taking the following structural cross-section of the manual diaphragm valve as an example, let's take a look at the diaphragm valve.

Basic Structure:

The valve body contains the fluid passage.

A flexible diaphragm is positioned inside the valve, separating the flow from the valve's operating mechanism.

A valve seat is where the diaphragm presses to block the flow.

Operation:

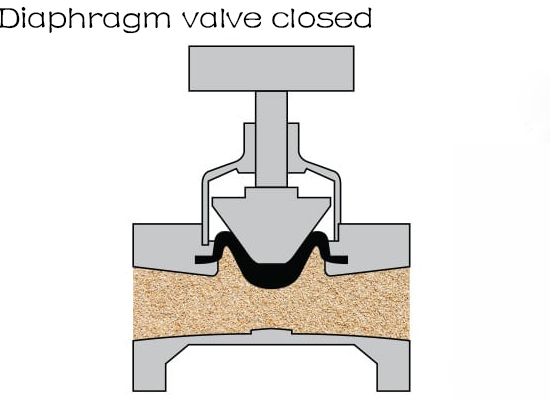

When the pneumatic actuator pushes the diaphragm downward, the diaphragm presses against the valve seat, sealing off the flow path and stopping the fluid flow.

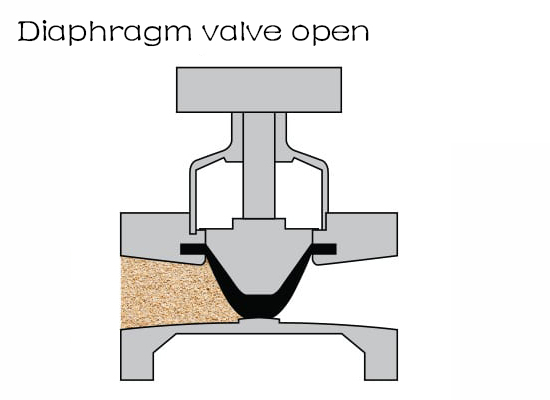

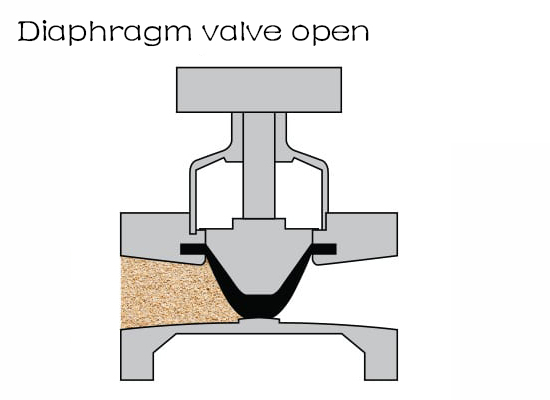

When the actuator lifts or relaxes the diaphragm, it moves away from the seat, allowing fluid to pass through the valve body freely.

Flow Control:

Because the diaphragm can be positioned at varying degrees between fully closed and fully open, the valve can regulate flow, not just stop it completely.

The design provides a smooth, straight flow path when open, minimizing turbulence.

Pneumatic Diaphragm Valve Manufacturer

As an one of experienced pneumatic diaphragm valve manufacturers and supplier , Fokca has with nearly 30 years of production experience, our team has excellent professional technical means and mature manufacturing technology,we commit to provide high-quality different Kinds Of Pneumatic diaphragm operated control valve designed for durability and performance. We offer a range of diaphragm valves to meet the diverse needs of industries like pharmaceuticals, chemicals, and food processing.

For more information like Basic Guide And Common Questions or to inquire about specific diaphragm valve solutions, please contact our team today!