May 21, 2025

A diaphragm valve is a type of valve that use diaphragm to control the flow of fluid using an elastic diaphragm. Its most notable feature is the complete separation between the valve body and the actuator, effectively preventing fluid from corroding or contaminating components such as the valve stem.Furthermore, due to the design of the diaphragm elastomer, particles and slurries in the fluid are less likely to accumulate, resulting in higher flow efficiency. Diaphragm valves are therefore widely used in piping systems handling sanitary, corrosive, or high-purity media.

Catalogue

◆Basic functions and working principles

◆Structure type

◆Application

◆Advantages and disadvantages

◆Related specifications and standards

◆Conclusion

◆Frequently asked questions

◆Basic functions and working principles

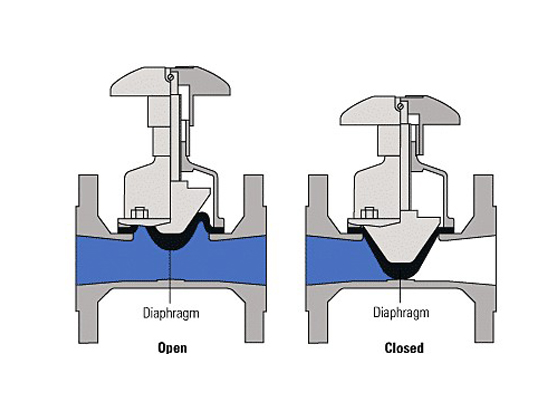

The working principle of a diaphragm control valve is simple and easy to understand. The diaphragm valve features a flexible diaphragm that, when actuated, can either allow or restrict the flow of fluid. The movement of the diaphragm is controlled by an actuator, which can be manual, pneumatic, or electric. When the diaphragm is pressed against the valve seat, fluid flow is stopped. Conversely, releasing pressure on the diaphragm allows the fluid to pass through the valve.Key functions of diaphragm valves include:

Compared to traditional valves, diaphragm control valves are favored in precise flow control applications due to the diaphragm's direct interaction with the flow path and its ability to deform and rebound repeatedly under actuation. The actuator lifts or presses the diaphragm in direct response to flow control needs.

Open Position: When the actuator lifts the diaphragm, the flow path inside the valve body is unobstructed, allowing fluid to flow freely.

Closed Position: When the diaphragm is pressed down, it seals tightly against the valve body’s flow port, effectively blocking the fluid path and achieving a secure seal.

The diaphragm vakve diaphragm serves as both a sealing and a flexible element, capable of repeated deformation and rebound, making it ideal for applications that demand high reliability and hygiene.

Diaphragm control valve can be classified into various types based on their driving and structural methods, each designed to meet specific applications:

Since the actuator of a diaphragm valve controls the internal diaphragm, diaphragm valves can be classified based on different types of actuation mechanisms:

Manual Diaphragm Valve

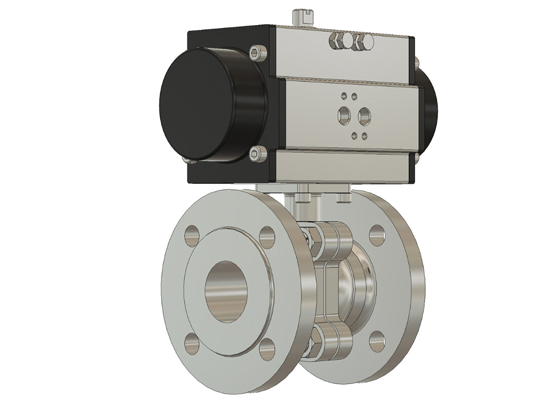

Pneumatic Diaphragm Valve

Electric Diaphragm Valve

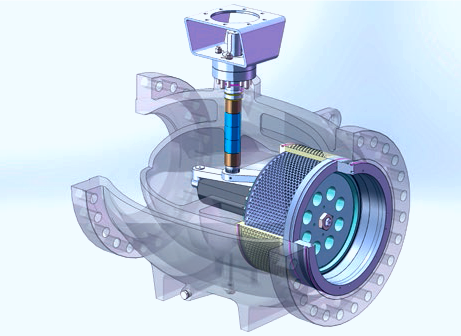

Straight-Through Diaphragm Valve: Features a simple, linear flow path, making it ideal for applications requiring unobstructed flow with minimal pressure drop.

Right-Angle Diaphragm Valve: Designed with a 90° angle, suitable for corner installations in piping systems.

Two-Way and Three-Way Diaphragm Valves: Two-way valves control flow between two points, while three-way valves can direct flow among three different paths, offering enhanced versatility.

Double-Diaphragm Design: This type is used in ultra-high-purity applications, such as in the pharmaceutical industry, where stringent cleanliness and contamination control are essential.

A diaphragm valve is composed of several key components, each playing a vital role in its operation:

Valve Body: The valve body is the main structure of the valve, providing mechanical support and housing the diaphragm. It must be compatible with both the fluid being handled and the diaphragm material to ensure durability and performance.

Diaphragm: Controlled by an external actuator, the diaphragm is responsible for precisely regulating the flow of fluid. It acts as both a sealing and flexible element, ensuring reliable operation and leak-free performance.

Supporting Components: These include seals, nuts, bolts, and other fastening elements. They ensure the valve remains securely assembled and functions efficiently under varying operating conditions.

Actuator: The actuator is responsible for moving the diaphragm. Manual diaphragm valves are operated by hand, while pneumatic diaphragm valves use compressed air, and electric diaphragm valves use electrical power to control the diaphragm’s motion.

Diaphragm valves are widely used across various industries due to their unique characteristics and high-performance capabilities:

Pharmaceutical Industry:Diaphragm valves play a critical role in pharmaceutical manufacturing, where maintaining sterile conditions is essential. They are used to control the flow of various liquids and gases throughout the drug production process.

Food & Beverage Industry:Diaphragm valves are extensively used in sanitary applications within the food and beverage sector. Processes such as bottling, brewing, and dairy production rely on diaphragm valves to ensure hygienic operation and prevent contamination.

Biotechnology:In the biotech field, diaphragm valves are essential for operations that require high purity and sterile environments. They are used to control the transfer of media, buffer solutions, and other process fluids, ensuring process stability and consistent product quality.

Chemical Industry:Diaphragm valves are widely adopted in chemical processing due to their excellent corrosion resistance. They are ideal for handling aggressive acids, bases, and other corrosive substances, preventing leaks and equipment damage while ensuring safety and operational continuity.

Electronics Industry:Diaphragm valves play a key role in electronics manufacturing, especially in the delivery of ultra-pure water and chemical reagents. Their non-metallic, contamination-free design ensures the purity of media, making them indispensable in precision processes such as semiconductor, flat-panel display, and chip fabrication.

Diaphragm valves have multiple advantages, making them the preferred choice for various industrial applications. However, they also have some limitations that need to be considered:

Advantages:

Completely isolate the fluid from the driving part to prevent contamination

Suitable for corrosive, granular, and viscous media

Simple structure and easy maintenance

Good sealing performance, no risk of leakage

Easy to clean

Disadvantages:

Limited fluid regulation accuracy.

Not suitable for systems with large flow rates or ultra-high-speed fluids.

Not suitable for high-pressure and high-temperature environments.

When the caliber is larger, the operating force increases or the cost rises

Compared with ordinary valves, Diaphragm valves with elastic diaphragms can also handle slurries and media containing solid particles, offering excellent sealing performance and precise flow control.

A diaphragm valve is a type of valve that uses a flexible diaphragm to regulate the flow of fluid. It isolates the flow medium from moving parts, making it ideal for sanitary and corrosive applications.

Diaphragm valves are commonly used in industries like pharmaceuticals, food and beverage, water treatment, and chemical processing due to their excellent sealing and resistance to corrosion or contamination.

The valve operates by moving a diaphragm up or down to open or close the flow path. When the diaphragm presses down against the valve seat, it stops flow; when lifted, it allows fluid to pass through.

Diaphragm valves can handle air, gases, and various liquid media, including corrosive liquids or liquids containing solid particles.

Diaphragm valves can be actuated by various methods, including manual, pneumatic, and electric drives, which move the valve stem in a linear up-and-down motion.

With its exceptional sealing performance and outstanding resistance to corrosive and abrasive media, the diaphragm valve has revolutionized fluid system management across various industries.Contact us directly to enquire more Latest Consultation!

By selecting and using diaphragm valves appropriately, industries can enhance production efficiency and system stability, while significantly reducing maintenance costs. This enables precise control and seamless transfer of fluids in complex process workflows. Therefore, gaining in-depth knowledge of diaphragm valves and their role in modern industrial applications is a key step toward achieving smart manufacturing and process optimization.

In addition, Fokcavalve also offers a variety of other valve types, including angle seat valves for medium shut-off applications, globe control valves for precise process control, solenoid valves for fast response, ball valves for reliable on/off control, axial flow valves featuring lower flow resistance, pressure regulating valves for maintaining system pressure stability, check valves to prevent backflow, and safety valves that provide auxiliary and protective functions.

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Apr 29, 2025 Blog

A Guide To Master Pneumatic Axial ValvesFOKCA ©1998-2025 All Rights Reserved Sitemap