Apr 16, 2025

Have you heard of angle seat valves? These automatio components play a crucial role in fluid and gas control systems, offering superior performance in a variety of industrial applications. Known for their unique angled seat design, angle seat valves provide high flow rates, low flow resistance, and exceptional durability. Their ability to control the flow direction and pressure of fluids makes them indispensable in pneumatic, hydraulic, and even chemical processing systems.

In this article, we'll dive into the design, benefits, and drawbacks of angle seat valves, as well as explore their various applications and types. Whether you're involved in automation, HVAC systems, or industrial fluid control, understanding how these valves function.Here is the table of contents for this article:

◆ Advantages and Disadvantages of Angle Seat Valve

◆ Factors when Considering Angle Seat Valve

Angle seat valve is a type of solenoid valve, and its unique foot seat design distinguishes it from other solenoid valves. The inclined installation surface inside the valve body and the valve seat sealing insert constitute the foot seat design. This design can achieve the maximum fluid path and minimize fluid pressure loss.

Characteristic

The angle seat valve has multiple angle designs, including 30 degrees, 60 degrees, and even 90 degrees. But the most common angle is 45 degrees. The 45 degree angle design not only makes the angled channel smoother, reduces turbulence and pressure drop, but also reduces the occupied space, which is more conducive to equipment integration.

Operate

There are two operating modes for angle seat valves: manual or automatic. Manual operation requires operators to directly open and close valves through mechanical means such as handwheels and handles; Automatic refers to the use of actuators, including electric or pneumatic, to control the automatic opening or closing of valves, in situations where frequent valve operation or remote operation is required.

The opening of an angle seat valve is generally achieved through three methods: manual, pneumatic, and electric. These methods operate the valve stem, causing it to move up and down, which in turn drives the valve plug to open or close.Here is a detailed introduction to these three opening methods:

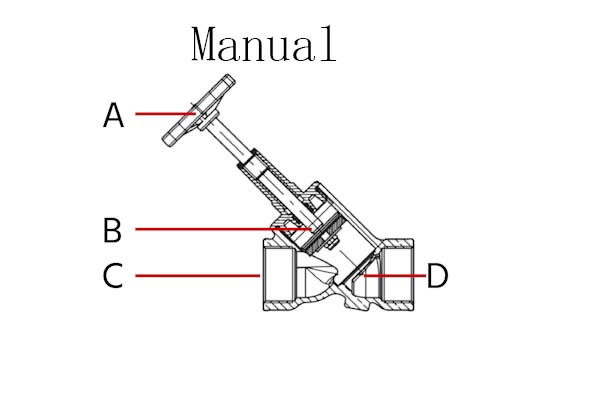

Manual:

Handwheel (A): The valve can be manually operated by rotating the handwheel to open or close the valve.

Plug/Valve Disc (B): Acts as the closing element inside the valve, sealing the fluid when the valve is closed.

Connection Ports (C): Serve as the interface for connecting the valve to the pipeline system, allowing the medium to flow through the valve.

Angle Valve Seat (D): Designed to ensure a tight seal when the valve is closed and effectively adjust the flow when opened, with its angled position enhancing flow dynamics.

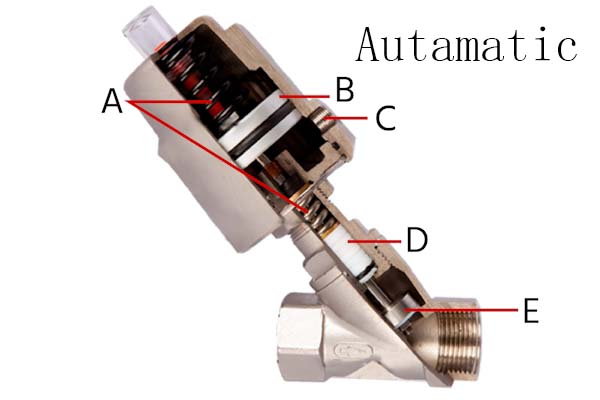

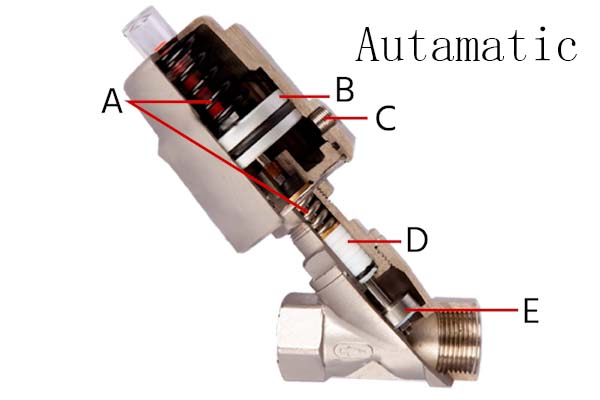

Automatic:

Spring Return (A): The spring return ensures that the valve returns to its original position (either open or closed) when no pneumatic pressure is applied.

Piston (B): The piston in the pneumatic angle seat valve serves as the driving force for the actuator. When compressed air enters the valve, it pushes the piston, and the linear motion is transferred to the valve core, either lifting it from the valve seat to open the valve or returning it to the seat to close the valve.

Air Port (C): The air port is the entry point for compressed air into the valve actuator chamber. Its size and design are crucial for controlling the airflow that drives the piston.

Packing (D): The packing provides a seal between the moving parts of the valve and the fixed components, particularly around the piston rod that connects the piston and valve core. This seal prevents controlled media from leaking from the valve body and prevents pressurized air from escaping.

Rotary Plug (E): The rotary plug or valve disc is the component that directly interacts with the valve seat to control the flow direction. When the piston lifts the rotary plug from the valve seat, the valve opens, allowing fluid to flow. When the rotary plug presses against the valve seat, the valve closes, stopping fluid flow.

Electric:The electric actuator in an angle seat valve is equipped with a motor that converts electrical energy into mechanical torque to precisely control the valve's opening and closing. The motor is typically paired with a gearbox to enhance torque output and control, allowing fine adjustment of the valve's position. Additionally, integrated sensors and control circuits within the actuator provide feedback on the valve's status and position, enabling real-time adjustments and automation.

Angle seat valves are ideal for many industrial applications due to their efficiency, durability, and versatility. However, it is important to carefully consider factors such as control complexity, installation, maintenance, and cost based on specific application needs.

Advantages:

High Flow Capacity, Low Pressure Loss: Like other valves,angle seat valves offer direct flow paths when open, significantly reducing flow resistance and pressure loss.

Durability and High Cycle Life: Known for their robust construction and ability to withstand harsh environments, angle seat valves are designed to endure extreme conditions. They are capable of handling high temperatures and high viscosity environments, making them suitable for demanding applications with an expected lifespan of over 10 million cycles.

Versatility: These valves can regulate liquids, gases, steam, and even corrosive fluids, offering great flexibility in various applications.

High-Temperature Applications: Featuring PTFE seals, angle seat valves can withstand temperatures up to 200°C (392°F), making them ideal for high-temperature environments.

Disadvantages:

Larger Actuators Require Stronger Return Springs: The increased pressure resulting from water hammer may require a stronger return spring. This necessitates a larger actuator to overcome the increased spring strength.

Installation and Maintenance Considerations: Proper installation and regular maintenance, as specified by manufacturers, are required to prevent leaks and ensure efficient operation. This added effort can be seen as a downside for some.

Cost: Due to their sturdy design and diverse material options, angle seat valves may have a higher initial cost compared to simpler valve types like ball valves or solenoid valves. However, the durability and extended service life of angle seat valves can offset their initial investment over time.

◆ Food and beverage industry

◆ chemical industry

◆ Oil and Natural

◆ wastewater

◆ pharmaceutical production

◆ Consider end connections and pipeline dimensions

◆ Working temperature

◆ Pressure and material properties

◆ Valve installation and maintenance

The opening and closing actions of this angle seat valve are accomplished by a pneumatic actuator.

Pneumatic angle seat valves use air pressure to move the piston, thereby opening or closing the valve to control flow.

Angle seat valves have high durability, excellent flow rates, and are suitable for harsh environments, making them more efficient than ball valves or solenoid valves.

Fokca is a professional manufacturer of pneumatic components based in Ningbo, specializing in a wide range of valves, including Angle Seat Valves, Globe Valves, Solenoid Valves, and other valve products. Additionally, we offer Pneumatic Components,Hoses & Connectors, Hydraulic Components, and other types of products.

As angle seat valve suppliers, we are dedicated to providing high-quality valves and components, meeting the needs of various industrial applications. Our company follows a professional production and service philosophy, with a strong focus on delivering top-notch products and services to become the leading exporter of startup products. We look forward to collaborating with you.

As a pneumatic products corporation, we are committed to delivering the best pneumatic products for diverse industries, ensuring the performance and reliability of your operations.

If you have any further information to consult, Welcome to our brand website:https://www.fokca.com/

You May Interest In

Apr 22, 2025 Blog

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap