Jul 08, 2025

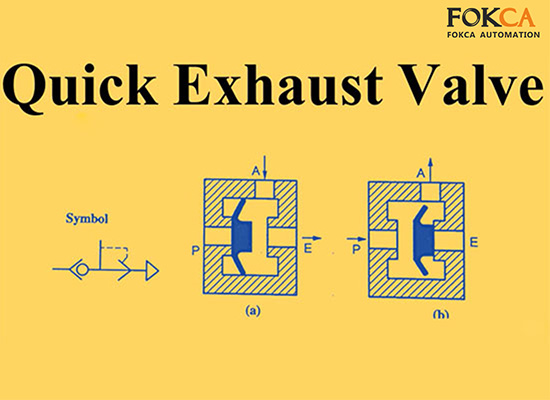

The Quick Exhaust Valve is a specialized air release exhaust valve component designed for pneumatic systems. It operates with significantly higher efficiency and precision compared to common exhaust valves, playing a core role in modern pneumatic applications and industrial automation. Due to its superior performance, it is widely utilized in packaging machinery, cylinder reset in stamping presses, and various other motion control applications.

The quick exhaust valve primarily is a kind of pneumatic valve designed to rapidly discharge air,it consists of an inlet port, an outlet port, an exhaust port, and a valve core. Its working principle involves driving cylinder movement while rapidly exhausting residual air pressure from the cylinder to significantly reduce reset time. In pneumatic systems, it serves critical functions including: optimizing exhaust pathways in pneumatic circuits, reducing backpressure, decreasing air compressor load, and protecting cylinders from water hammer effects caused by poor exhaust performance.

Significantly improves operational efficiency: Utilizes a more direct atmospheric exhaust path to achieve faster air cycling.

Energy-saving performance: Reduces backpressure in pneumatic systems, effectively lowering air compressor workload and energy consumption by 15-25%.

Enhanced equipment protection: Prevents water hammer effect and minimizes impact damage to cylinders and system components.

Cost-effective: Extends component lifespan while requiring minimal maintenance.

The pneuamtic quick exhaust valve is a specialized valve used in pneumatic systems, primarily designed to accelerate the exhaust speed of cylinders, thereby improving the response speed and efficiency of cylinder operation. It is usually installed near the cylinder’s exhaust port, utilizing its valve structure to minimize the exhaust path.

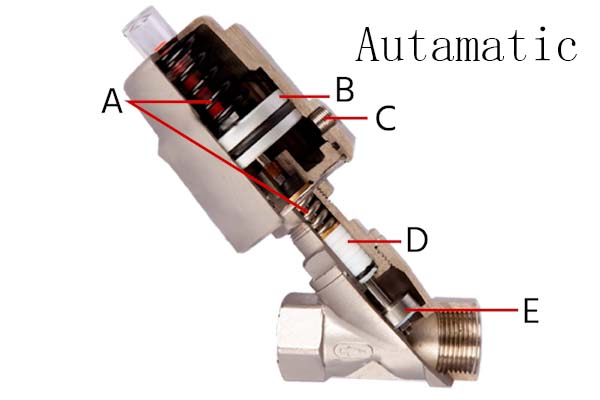

Structural composition

Supply Port: An intake pipe that connects to a gas source or cylinder

Exhaust Port: Connect to exhaust pipe or atmosphere

Control Port: Connect the exhaust end of the cylinder

Valve Spool or Poppet: Automatically switches positions according to changes in air pressure to achieve on/off air flow

Spring: Assist in resetting the valve core

Workflow

When the cylinder is inflating, compressed air flows from the air source through the inlet port of the quick exhaust valve. The valve spool, under the force of the spring, keeps the exhaust port closed, allowing the airflow to smoothly enter the cylinder and drive the piston movement.

When the cylinder is exhausting, and the piston reaches the end of its stroke, the exhaust pressure acts on the control port, pushing the valve spool to open the quick exhaust outlet. The air is then discharged directly to the atmosphere through the exhaust port, bypassing the narrower passage of the valve's inlet.

The quick exhaust valve operates based on the cylinder’s motion. Simply put, it does not interfere with the cylinder during air intake. Its primary function takes place during exhaust, where it shortens the exhaust path to speed up the cylinder's return or switching action.

A Quick Exhaust Valve is designed to rapidly vent exhaust air from a pneumatic actuator directly to the atmosphere, rather than routing it back through control valves or long piping.

Improve cylinder operating speed: By quickly exhausting nearby, accelerate cylinder return or direction change.

Shorten exhaust path: Reduce the resistance of gas passing through control valves or long pipelines.

Improve system efficiency: Especially suitable for high-speed and frequently operated pneumatic equipment.

Reduce system energy consumption: The exhaust process is smoother and the system load is reduced.

Interface size matching

Common thread or quick insert specifications that match the cylinder port or pipe diameter include G1/8 ", G1/4", G3/8''.

Traffic capacity

The larger the flow rate, the faster the exhaust. For large or high-frequency cylinders, high flow valves should be selected.

Applicable pressure range

Confirm that the rated working pressure of the valve can cover the system pressure.

Installation structure requirements

Choose the appropriate structural form based on whether the installation space is limited and whether brackets or quick connectors are needed.

Environmental adaptability

If in high-temperature, dusty, and explosion-proof areas, stainless steel material or sealed structure should be selected.

With or without noise reduction function

Some models come with silencers or can be equipped with external silencers, suitable for places with noise requirements.

◆ Accelerating cylinder return action

◆ Large cylinder or long pipe system

◆ Implement simple pneumatic logic control

◆ Enhance security performance

◆ Non electric control systems in explosion-proof or special environments

In summary,quick exhaust valve applications in pneumatic systems focus on enhancing speed, efficiency, and safety—especially where fast cylinder retraction, long pipelines, or non-electrical environments are involved.

Confirm installation position: Confirm that the valve should be installed on the exhaust side of the cylinder, as close as possible to the cylinder body.

Check valve ports: Check that the intake, connecting cylinders, and exhaust ports are functioning properly.

Connecting pipeline: Use compatible threaded or quick connect fittings to correctly connect the quick exhaust valve to the air pipe between the cylinder and the control valve.

Fixed valve body: Fix the valve in a stable position to avoid shaking or loosening during operation.

Test exhaust effect: Observe whether fast and smooth exhaust can be achieved, and check for any air leaks.

In modern pneumatic systems, Quick Exhaust Valve has become an essential component for improving equipment response speed and efficiency. A suitable quick exhaust valve can not only extend the service life of equipment, but also help you reduce maintenance costs and improve system stability.

We are a professional manufacturer and supplier of China Quick Exhaust Valve, committed to providing high-performance and high reliability pneumatic control components to customers worldwide. Full range specifications, using high-quality materials and precision structural design. Every product undergoes strict testing before leaving the factory and meets multiple international standards such as ISO and CE.

We provide one-stop services such as selection consultation, technical guidance, installation suggestions, etc.

Choosing the appropriate Quick Exhaust Valve is not only about improving speed, but also a crucial step in enhancing efficiency and competitiveness. Welcome to contact us for more product details, we will be dedicated to serving you!

Pneumatic Actuator: The Core Power Unit Behind Industrial Automation

Pneumatic Actuator: The Core Power Unit Behind Industrial Automation

Why Food Grade Diaphragm Valve Has Become the Standard in Hygienic Piping Systems

Why Food Grade Diaphragm Valve Has Become the Standard in Hygienic Piping Systems

AV700 Series Fill Valve: A Comprehensive Application Guide

AV700 Series Fill Valve: A Comprehensive Application Guide

Pilot Pressure vs Working Pressure in Industrial Valves: Key Differences and Selection Guide

Pilot Pressure vs Working Pressure in Industrial Valves: Key Differences and Selection Guide

Water Hammer Explained: Why Angle Seat Valves Are the Optimal Solution

Water Hammer Explained: Why Angle Seat Valves Are the Optimal Solution

You May Interest In

Jul 30, 2025 Blog

AWG:Why do We Need the American Wire Gauge?

Jul 28, 2025 Blog

How to check air solenoid valve?

Jul 24, 2025 Blog

How to check the solenoid valve?

Apr 22, 2025 Blog

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap