Jul 24, 2025

The solenoid valve is a key actuator for achieving automated control, widely used to open, close, or switch the flow paths of liquids, gases, or oils. It converts electrical signals into mechanical actions and serves as the bridge between the control system and the actuating device. Regular inspection of solenoid valves is a necessary measure to ensure the system’s safe, efficient, and reliable operation. It helps prevent failures, reduce losses, and extend the overall equipment lifespan while improving production efficiency.

The inspection includes:

◆ Testing whether the valve operates normally

◆ Checking for air leaks or leakage

◆ Inspecting the solenoid coil for damage

◆ Testing if the control signal is properly received

◆ Testing whether the valve core switches sensitively

◆ Checking the valve body for damage or blockage

Necessary inspections are crucial to ensure that a solenoid valve functions properly. Compared to the inspection of pneumatic solenoid valves, the inspection of a typical electric flow control valve is generally less complex.

You need to conduct a detailed inspection of the soleoid valve according to the following testing steps, including appearance and performance.

Items to check:

• Whether the housing is damaged or deformed (e.g., due to impact or aging)

• Whether there is contamination from oil, water, or dust

• Whether the coil, connectors, or plugs are loose or detached

• Whether the label and model number are correct (to prevent misuse)

Precautions:

• Housing deformation may cause the coil or valve core to jam

• Loose plugs can cause the coil to lose power connection

Tools:

• Multimeter

Items to check:

1. Measure resistance with a multimeter

Remove the coil and measure the resistance across its two terminals using the ohm setting

Normal resistance is usually between several tens to several hundred ohms (depending on the model)

Resistance = 0 ➜ short circuit; Resistance = infinity ➜ open circuit (coil is burnt out)

2. Check if the coil actuates when powered

Listen for a “click” sound after powering the coil

If there is no action, possible causes include a faulty coil, incorrect power supply, or valve core stuck

Precautions:

• Pay attention to voltage rating (24VDC / 110VAC / 220VAC); applying wrong voltage may damage the coil

• Some solenoid valves with a manual test button can be manually operated to check if the valve core is functioning properly.

Items to check:

• Whether the voltage output from the controller or PLC is normal

• Whether the plugs and terminals are properly connected

• Whether the correct polarity of the DC power supply is used

Tools:

• Multimeter for voltage measurement

• Oscilloscope can be used to observe pulse control signals

Items to check:

• Whether the valve switches the air (or liquid) path after power is applied

• Whether the actuator (e.g., cylinder) operates

• Whether there is delay, sticking, or abnormal noise

Methods:

• Observe whether the valve switches in the powered on/off state

• For pilot-operated valves, ensure the minimum working pressure is maintained

• If the action is sluggish, there may be internal dirt, insufficient lubrication, or wear

Areas to inspect:

• Connection points (inlet/outlet/exhaust ports)

• Valve body joints

• Internal valve spool seals

Inspection methods:

• Apply soapy water to check for bubbles (gas leakage)

• Observe whether there is continuous exhaust or pressure leakage at the output

• Use a pressure gauge to check for abnormal pressure drop

Precautions:

• Common causes: aging O-rings, worn valve spools, foreign objects stuck on sealing surfaces.

Methods:

• Supply air in the powered state to confirm whether gas can pass through the valve smoothly

• Check whether it can fully close in the powered-off state

• Use a flow meter or pressure gauge for testing

Precautions:

• Some solenoid valves have internal filters or throttling orifices, which are prone to clogging by dust or oil residue.

The solenoid valve should be inspected before and during operation, followed by proper maintenance. Refer to the table below for maintenance guidelines.

| Maintenance Task | Description |

| Clean external dust | Prevents overheating or short circuits in the solenoid coil. |

| Disassemble and clean internals | Clean the valve spool, seals, and sliding parts. |

| Check coil resistance | Determine if aging has occurred; replace if resistance deviates significantly. |

| Inspect O-rings and seals | Replace if cracks or signs of aging are present. |

| Check wiring terminals | Tighten screws to prevent poor contact. |

• Solenoid Coil

• Valve Spool Assembly

• Sealing Rings/O-Rings

• Plugs and Cables

• Springs

Inspecting a solenoid valve involves comprehensively verifying whether it is energized, switches properly, maintains sealing integrity, and allows unobstructed flow, while systematically troubleshooting any abnormalities by integrating both electrical and pneumatic components. Regular maintenance is critical to ensuring its long-term stable operation.If you want more information about electric flow conrol valve,Contact us directly!

System Problems Caused by Incorrect Port Identification of 3 Way Solenoid Valve

System Problems Caused by Incorrect Port Identification of 3 Way Solenoid Valve

Advantages of 3 Way Solenoid Valve in Single Acting Cylinder Control

Advantages of 3 Way Solenoid Valve in Single Acting Cylinder Control

Supply and Exhaust Logic of Normally Open and Normally Closed 3-Way Solenoid Valves

Supply and Exhaust Logic of Normally Open and Normally Closed 3-Way Solenoid Valves

Application Scenarios of Mixed Flow Path Design in 3-Way Solenoid Valves

Application Scenarios of Mixed Flow Path Design in 3-Way Solenoid Valves

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

You May Interest In

Jul 30, 2025 Blog

AWG:Why do We Need the American Wire Gauge?

Jul 28, 2025 Blog

How to check air solenoid valve?

Jul 24, 2025 Blog

How to check the solenoid valve?

Apr 22, 2025 Blog

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

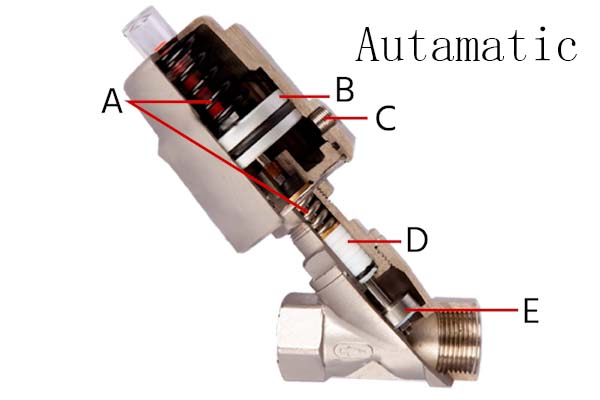

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap