Jul 30, 2025

In 1871, an unprecedented fire swept through Chicago, claiming nearly 300 lives and leaving about 100,000 homeless, making it one of the worst disasters of the 19th century in the United States.

While the primary cause of the fire was dense wooden structures, subsequent investigations revealed that inconsistent electrical wire specifications leading to short circuits were a significant contributing factor. At the time, so-called "12-gauge wires" varied in diameter by up to 15% between buildings, causing overloaded heating that ignited insulation materials.

Coincidentally, in 1872, Edison's first commercial power station opened on Pearl Street, marking the dawn of the electric light era. However, because suppliers provided "identical specification" wires with actual cross-sectional areas differing by nearly 30%, some wires overheated and melted, resulting in multiple power outages during the station's first month of operation. Edison had to wrap the wires in tin foil as a temporary solution.

During the Industrial Revolution, the electrification process exposed a severe lack of standards, with similar accidents occurring countless times. In fact, as early as 1855, Brown & Sharpe introduced the first commercial wire gauge, but it only covered wire diameters from 6 to 36 AWG and was not widely adopted.

Fortunately, in 1903, the NEC(National Electrical Code) codified the AWG standard for the first time. Within three years of implementation (1903–1905), the elimination rate of wire factories in the United States is close to 41%, but the incidence of electrical fires dropped by about 58%. In 1911, General Electric mandated that all suppliers use standardized AWG molds and implemented strict testing standards, significantly reducing motor failure rates.

The full name of AWG is American Wire Gauge. It uses mathematical formulas to define a series of wire models and dimensions, including diameter, cross-sectional area, and resistance values. The larger the wire diameter, the larger the cross-sectional area, the lower the resistance, and the greater the current it can carry.

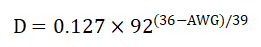

The conversion relationship between wire diameter and AWG is as follows:

The conversion relationship between wire diameter and AWG is as follows:

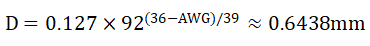

For AWG22, substituting into the formula:

Of course, you can also directly refer to the AWG reference table for specific parameters.

AWG | Outer Diameter | Cross-Sectional Area (mm2) | DC resistance (Ohm/km) | AWG | Outer Diameter | Cross-Sectional Area (mm2) | DC resistance (Ohm/km) | ||

Diameter (mm) | Diameter (inch) | Diameter (mm) | Diameter (inch) | ||||||

4/0 | 11.68 | 0.46 | 107.22 | 0.17 | 22 | 0.643 | 0.0253 | 0.3247 | 54.3 |

3/0 | 10.40 | 0.4096 | 85.01 | 0.21 | 23 | 0.574 | 0.0226 | 0.2588 | 66.8 |

2/0 | 9.27 | 0.3648 | 67.43 | 0.26 | 24 | 0.511 | 0.0201 | 0.2047 | 89.4 |

1/0 | 8.25 | 0.3249 | 53.49 | 0.33 | 25 | 0.44 | 0.0179 | 0.1624 | 106 |

1 | 7.35 | 0.2893 | 42.41 | 0.42 | 26 | 0.404 | 0.0159 | 0.1281 | 143 |

2 | 6.54 | 0.2576 | 33.62 | 0.53 | 27 | 0.361 | 0.0142 | 0.1021 | 168 |

3 | 5.83 | 0.2294 | 26.67 | 0.66 | 28 | 0.32 | 0.0126 | 0.0804 | 227 |

4 | 5.19 | 0.2043 | 21.15 | 0.84 | 29 | 0.287 | 0.0113 | 0.0647 | 289 |

5 | 4.62 | 0.1819 | 16.77 | 1.06 | 30 | 0.254 | 0.0100 | 0.0507 | 361 |

6 | 4.11 | 0.1620 | 13.30 | 1.33 | 31 | 0.226 | 0.0089 | 0.0401 | 430 |

7 | 3.67 | 0.1443 | 10.55 | 1.68 | 32 | 0.203 | 0.0080 | 0.0316 | 583 |

8 | 3.26 | 0.1285 | 8.37 | 2.11 | 33 | 0.18 | 0.0071 | 0.0255 | 944 |

9 | 2.91 | 0.1144 | 6.63 | 2.67 | 34 | 0.16 | 0.0063 | 0.0201 | 956 |

10 | 2.59 | 0.1019 | 5.26 | 3.36 | 35 | 0.142 | 0.0056 | 0.0169 | 1,200 |

11 | 2.30 | 0.0907 | 4.17 | 4.24 | 36 | 0.127 | 0.0050 | 0.0127 | 1,530 |

12 | 2.05 | 0.0808 | 3.332 | 5.31 | 37 | 0.114 | 0.0045 | 0.0098 | 1,788 |

13 | 1.82 | 0.0720 | 2.627 | 6.69 | 38 | 0.102 | 0.0040 | 0.0081 | 2,400 |

14 | 1.63 | 0.0641 | 2.075 | 8.45 | 39 | 0.089 | 0.0035 | 0.0062 | 2,740 |

15 | 1.45 | 0.0571 | 1.646 | 10.6 | 40 | 0.079 | 0.0031 | 0.0049 | 4,080 |

16 | 1.29 | 0.0508 | 1.318 | 13.5 | 41 | 0.071 | 0.0028 | 0.0040 | 4,264 |

17 | 1.15 | 0.0453 | 1.026 | 16.3 | 42 | 0.064 | 0.0025 | 0.0032 | 6,300 |

18 | 1.02 | 0.0403 | 0.8107 | 21.4 | 43 | 0.056 | 0.0022 | 0.0025 | 6,936 |

19 | 0.912 | 0.0359 | 0.5667 | 26.9 | 44 | 0.051 | 0.0020 | 0.0020 | 9,180 |

20 | 0.813 | 0.0320 | 0.5189 | 33.9 | 45 | 0.046 | 0.0018 | 0.0016 | 10,200 |

21 | 0.724 | 0.0285 | 0.4116 | 42.7 | 46 | 0.041 | 0.0016 | 0.0013 | 16,300 |

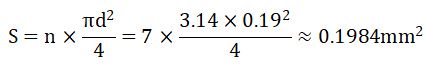

Suppose a small solenoid valve from Fokca uses a wire composed of 7 strands, each with a diameter of 0.19mm. What AWG standard does this wire comply with?

Referring to the AWG reference table, the diameter specified for AWG24 is 0.205mm², indicating that this solenoid valve's wire roughly meets the AWG24 standard.

If the actual requirement requires this solenoid valve to meet the AWG22 standard, how can it be modified to comply?

Referring to the AWG22 standard, the cross-sectional area is 0.3247mm².

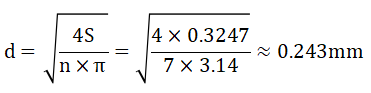

Option 1: Increase the wire diameter while keeping the number of strands unchanged

Thus, the diameter of each strand needs to be increased to 0.243mm.

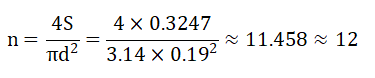

Option 2: Keep the wire diameter unchanged but increase the number of strands

Thus, the number of strands needs to be increased to 12.

Today, electricity is deeply intertwined with our lives, and AWG is widely applied in various fields. Common headphone wires are typically 28–24 AWG, while fast-charging phone cables are 20–24 AWG. The U.S. NEC standard also specifies clear requirements for residential wiring: a minimum of 14 AWG for 15A circuits and 12 AWG for 20A circuits.

In automation, the most common solenoid valves use different AWG standards depending on their purpose. For example, 24VDC solenoid valves typically use 24–30 AWG with currents of 0.1–0.5A, while 220VAC solenoid valves mostly use 32–36 AWG with currents of 0.01–0.1A.

In the new energy sector, Tesla's V3 Supercharger uses liquid-cooled cables with conductors composed of multiple parallel 2 AWG wires.

As the 1915 Electrical World magazine stated: "A seemingly dry set of numerical standards (AWG) is, in fact, the cornerstone of electrical civilization." Today, the plug specifications and circuit breaker parameters we take for granted are all built on the victory of this "wire gauge war."

Fokca is a company specializing in the production of pneumatic components. We manufacture various valves, including solenoid valves, angle seat valves, shuttle valves, and ball valves, and provide comprehensive supporting services. If you have any needs, please visit our Product for more information.

We are also happy to share knowledge. You can visit our Blog, where we provide additional resources, including articles, images, videos, and technical parameters, to help you better understand pneumatic products.

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

You May Interest In

Jul 30, 2025 Blog

AWG:Why do We Need the American Wire Gauge?

Jul 28, 2025 Blog

How to check air solenoid valve?

Jul 24, 2025 Blog

How to check the solenoid valve?

Apr 22, 2025 Blog

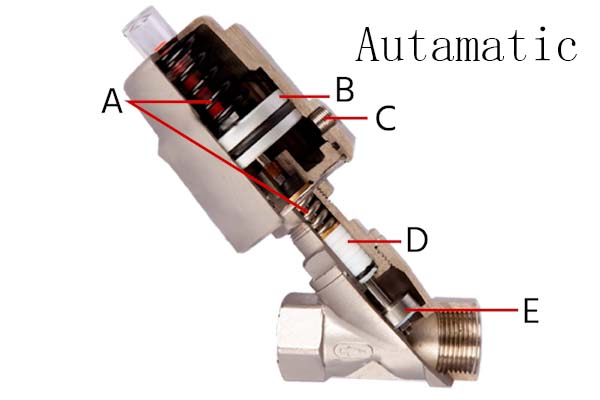

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap