Jul 01, 2025

A safety valve is a type of passive control valve that relies on the fluid's own pressure or action to open and close.Passive control means Safety valve is a critical safety device designed to automatically release pressure from a system when the internal pressure exceeds a preset limit. It serves as the last line of defense in pressurized systems, preventing equipment damage, system failure, or catastrophic explosions caused by overpressure.

A safety valve is a type of passive control valve that relies on the fluid's own pressure or action to open and close.It has many advantages as follows:

Overpressure Protection

Automatically releases pressure when it exceeds the set limit, preventing equipment damage or explosions.

Reliable and Autonomous Operation

Operates independently without requiring external power or control signals.

Simple and Robust Design

Fewer moving parts ensure high reliability and low maintenance requirements.

Fast Response Time

Instantaneous pressure relief minimizes system risks.

Cost-Effective Safety Solution

Prevents costly downtime, repairs, and safety incidents.

A safety valve is a type of passive control valve that relies on the fluid's own pressure or action to open and close.It can demonstrate advantages in the following application scenarios:

Boilers and Pressure Vessels

Protects against overpressure in steam boilers, autoclaves, and storage tanks.

Oil and Gas Industry

Used in pipelines, separators, and compressors to prevent pressure buildup.

Chemical and Petrochemical Plants

Safeguards reactors, heat exchangers, and processing equipment.

Power Generation

Ensures turbine, boiler, and auxiliary system safety in power plants.

Water and Wastewater Systems

Prevents overpressure in pump systems, filtration units, and storage tanks.

Pharmaceutical and Food Industry

Ensures pressure stability in sanitary and hygienic systems.

Fire Protection Systems

Used to control pressure in fire suppression pipelines and systems.

A safety valve is a type of passive control valve that relies on the fluid's own pressure or action to open and close.Here is an introduction to its specific workflow:

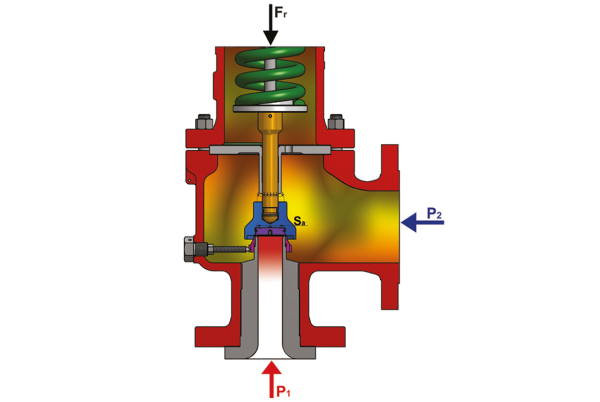

P1 represents the system pressure entering the valve, acting on the lower surface area.

When the system pressure P1 is below the set value, the spring force Fr is greater than the fluid pressure force (P1 ×

You May Interest In

Jul 30, 2025 Blog

AWG:Why do We Need the American Wire Gauge?

Jul 28, 2025 Blog

How to check air solenoid valve?

Jul 24, 2025 Blog

How to check the solenoid valve?

Apr 22, 2025 Blog

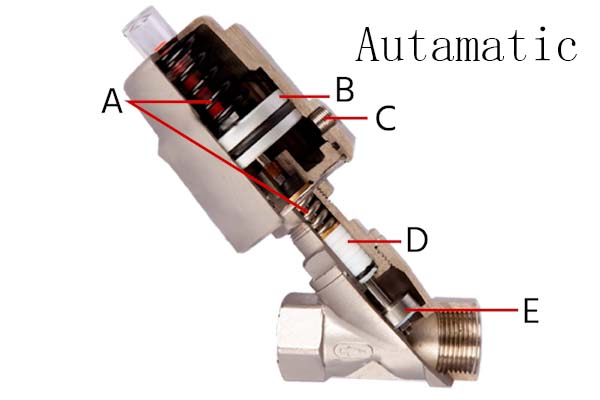

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap