Jun 09, 2025

Pulse solenoid valves are also commonly referred to as pulse solenoid diaphragm valves, as their internal structure typically adopts a diaphragm design. The diaphragm is actuated by a pilot valve that is controlled by an electric solenoid, enabling rapid movement of the diaphragm to release compressed air in short, powerful pulses.

The pulse solenoid valve is a core control component in automated dust removal and filtration systems. It operates by rapidly opening and closing to control the pulsed release of compressed air, effectively cleaning filter bags or cartridges. This process ensures continuous system operation and efficient filtration.There are generally two common structural types of pulse solenoid valves:Direct-acting pulse solenoid valves and Pilot-operated pulse solenoid valves.

A pilot-operated pulse solenoid valve is a specially designed solenoid valve that combines pilot control and pulse drive technologies. It is widely used in fluid control applications requiring fast response, low power consumption, or high-frequency switching.

Pilot operated pulse solenoid valve component is a pulse solenoid valve device that controls the action of a small pilot valve through electrical signals, and then triggers the opening of the main valve by the pilot valve to achieve instantaneous discharge of high flow gas.

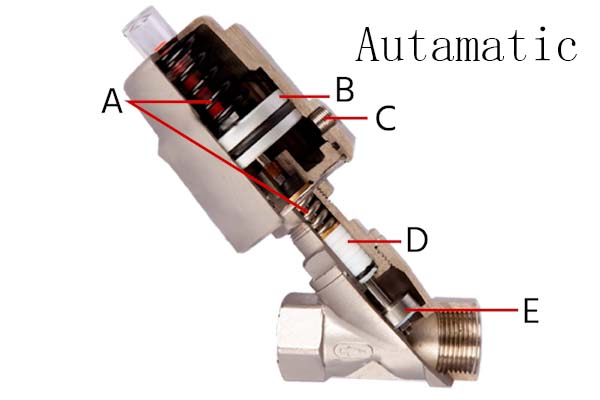

Electromagnetic Pilot Valve:Receive electrical signals and control the flow of air.

Main Valve Body:Endure and release high-pressure compressed air to achieve high flow injection.

Diaphragm component:Control valve opening/closing, core actuator.

Wiring interface:Common types include pin type, lead type, or DIN connectors.

Casing:Mostly made of aluminum alloy or stainless steel, suitable for harsh working conditions.

Pilot-Operated Structure:

A small pilot valve controls the opening or closing of the main valve.

When the pilot valve is energized, it uses fluid pressure differentials to actuate the main valve spool, reducing the power requirement of the solenoid coil.

Pulse Drive:

The valve position switches based on a brief electrical pulse signal,eliminating the need for continuous power.

The spool is held in position by permanent magnets or mechanical latching, significantly improving energy efficiency and reducing heat generation.

Pilot operated pulse solenoid valves are widely used in various industrial dust removal and air purification systems. Their core function is to perform instantaneous pulse blowing under system control, effectively removing dust on the surface of the filter medium, improving filtration efficiency and equipment life.

bag-type dust collector:The most typical application scenario of electromagnetic pulse valves is to remove dust on the surface of filter bags through pulse blowing, maintain ventilation capacity and filtration effect.

Pneumatic dust cleaning system:Suitable for dust cleaning in dust collection bins and pneumatic conveying pipelines. The rapid blowing action is suitable for removing adhesive powders or high dust loads.

Industrial filter cartridge system:The filter element is a filter cartridge rather than a filter bag, suitable for situations where space is limited or higher filtration accuracy is required. Such as laser cutting smoke purification equipment, sandblasting machine dust removal device, etc.

Smoke and dust purification and exhaust gas treatment system:Widely used in high dust conditions such as welding, metal processing, and boilers, effectively improving environmental compliance rates.

Operating principle

By triggering the pilot valve through the electronic control system, the pressure difference between the upper and lower chambers of the diaphragm is controlled to achieve instantaneous opening and closing of the main valve, forming high-speed airflow pulses.

Instantaneous high-pressure injection.

The spraying time is usually between 50-200 milliseconds, and compressed air is used to blow back the filter bag or filter cartridge, causing the surface dust to quickly fall off.

Accurately control the spraying cycle and width

Adjust the pulse interval and pulse width of the spray;

To avoid excessive frequency causing waste of compressed air and to prevent slow blowing from affecting the cleaning effect;

It can be combined with a differential pressure sensor to enable differential pressure control and achieve intelligent triggering of dust cleaning.

Match valve body flow rate with system air pressure

The valve body diameter, diaphragm opening speed, and airbag capacity should be consistent with the number of filter bags and system flow design;

The use of high flow solenoid valves can meet high dust load applications;

Maintaining a stable gas source of 0.4~0.6 MPa is the foundation for efficient ash cleaning.

Reasonable Zone based Management

Divide the dust removal system into multiple cleaning zones to avoid pressure drop caused by simultaneous spraying;

Implementing zone oriented spraying and delayed switching can maintain air pressure and improve dust removal uniformity.

Reduce airflow interference

Optimize the installation position of the valve body, and align the nozzle angle vertically with the center of the filter bag or filter cartridge to ensure effective airflow impact;

Try to use structures with silencers to reduce airflow disturbance and noise pollution.

Finally,Regularly maintain the diaphragm and pilot valve.

Pre-Installation Checks: Verify that the solenoid coil voltage matches your power supply.

Valve Positioning: Mount the valve in a vibration-free, dust-free location and Ensure the flow direction matches the valve's arrow indicator.

Pneumatic Connection: Use BSP/NPT/Metric threaded ports with appropriate sealants and Tighten fittings with a wrench but avoid over-torquing.

The final step is Electrical Wiring,Connect wires to the solenoid coil terminals and Initial Testing,Power on at low pressure to check for leaks.

Regular maintenance and upkeep

Cleaning and maintenance of valve core

Seal maintenance

Stainless steel valve body is selected for dust environment

Choose low-power coils for high-frequency applications

Compared to traditional valves, pulse solenoid valves offer faster response times, more precise control, and higher system integration efficiency, making them particularly suitable for applications such as pulse-jet cleaning systems, bag filters, and automated cartridge filtration equipment.

Whether you are a purchasing manager, an engineer, or a project manager planning a new dust collection system, now is the best time to learn about and select the right pulse solenoid valve for your needs.

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Jul 30, 2025 Blog

AWG:Why do We Need the American Wire Gauge?

Jul 28, 2025 Blog

How to check air solenoid valve?

Jul 24, 2025 Blog

How to check the solenoid valve?

Apr 22, 2025 Blog

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap