Solenoid(Electromagnetic) valve is an kind of electromechanical integrated control valve,used for precise control of fluid media in conveying pipelines in systems. It uses electrical signals to drive electromagnets, thereby opening or closing valves, controlling fluid flow, and regulating flow rate. Electromagnetic valves can play a crucial role in industries that require automatic flow control and modular remote regulation, such as industrial automation, water treatment and irrigation systems, medical and food and beverage industries, which cannot do without the presence of electromagnetic valves.

As modern industries increasingly rely on remote and programmable operations, A solenoid valve is an electric output device that converts electrical energy into a linear mechanical force. It enables precise control over parameters such as the on/off state, direction, flow rate, and speed of liquids or gases through electromagnetic action, significantly enhancing the automation level, response speed, and operational efficiency of industrial systems.Solenoid valve is widely used in industries such as manufacturing, automotive, oil and gas, and water treatment.

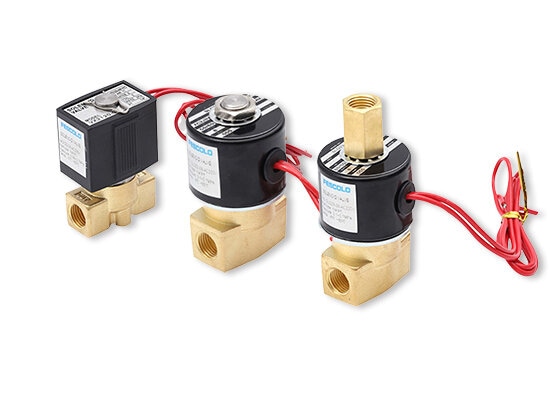

The solenoid valve is an kind of automatic control component that controls the airflow direction in valve actuator through an electromagnetic coil. The structure of electronic solenoid valves mainly includes the coil, valve spool, spring, valve body, and other parts. During operation, the coil is energized to generate magnetic force, which drives the valve spool to switch the air passages, enabling the flow or cut-off of air, thereby controlling the action of actuators.

This solenoid valve features fast response, compact structure, and precise control. It is widely used in automated production lines, packaging machinery, automotive manufacturing, food processing, electronic assembly, and other industrial fields,electronic solenoid valve is serving as a core control component in modern pneumatic systems.

The advantages of solenoid valve can generally be described from multiple aspects, including size and specifications, materials, structure, brand, specific applications, pressure range, and ease of installation and maintenance.

Size

Small type of solenoid valve features a compact size, low power consumption, various connection and installation options, and are available in materials such as stainless steel, brass, and engineering plastics. They are suitable for air, water, and even corrosive fluids.Taking the American standard solenoid valve as an example, medium-size solenoid valves offer strong versatility.High-flow solenoid valve features a high-strength structure, ultra-high flow capacity, adaptability to higher pressure and temperature, and offer multiple control options along with flange, G, and NPT connection types.

Structure

Regardless of size, the soleoid valve will vary in ways and valve positions.A 2-way solenoid valve only has an on/off function, regardless of whether it controls mixed fluids or compressed air. A 3-way solenoid valve is used to switch the direction and flow of fluids on and off. The 5-way solenoid valve offers better integration, making it easier to control in complex pneumatic systems.Regardless of the number of ports, the working positions are limited: a 2-position valve has only open and close states, while a 3-position valve adds a middle pause position.The more ports and positions a solenoid valve has, the stronger its control capability is, allowing it to manage more complex systems.

Material

Stainless Steel Solenoid Valve has Strong corrosion resistance, high strength, long service life, low maintenance cost;Brass Solenoid Valve has the advantages of Low cost, high cost-effectiveness, easy processing and installation, wide applicability, good mechanical performance, suitable for media such as water, air, and oil, compact structure, light weight.

The size specifications, materials used, and structures of solenoid valve differ, but it can each perform unique functions in various industries.

Switching the direction of the air path: controlling the airflow to different channels, achieving actions such as cylinder expansion and contraction, gripper opening and closing.

Keep the gas path sealed: Prevent gas leakage and ensure stable system pressure.

Realize complex control capabilities: Pneumatic solenoid valve features multi-position and multi-port configurations such as 3/2, 4/2, 5/2, and 5/3, offering more powerful control capabilities compared to solenoid valves used for mixed media.

Realize multi-channel control: By combining multiple channels, complex pneumatic action sequences can be achieved.

Active control: External energy is actively applied to control the electromagnetic coil to generate a magnetic field.

Automatic filling equipment: They can directly control the start stop control of the gas source.

Industrial automation equipment: Solenoid control valve can be used to control the execution structure of high-speed reciprocating motion.

CNC equipment and robotic arms: electrically control valve devices that require pause, buffering, and precise positioning in intermediate states.

Medical and laboratory equipment: 2 way electric valve can control various media channels such as pure water, oxygen, medicine, gas, etc., quickly cut off, and have good sealing performance.

Industrial automation equipment: 3-Way type soleoid valves switch gas/liquid flow paths between three-way positions to achieve fluid medium diversion or reversal.

A solenoid valve is an electric actively control valve actuator that converts electrical energy into a linear mechanical force. There some solenoid valves types provided by fokca as follows:

pulse solenoid valve: This type electrical valve is controlled by pulse signals, offering fast response and low power consumption, and is typically in a normally closed state. It has a simple structure with a spring return mechanism.

pneumatic solenoid valve: Designed specifically for controlling compressed air, this solenoid valve features high-pressure resistance and corrosion-proof construction. It operates in either direct-acting or pilot-operated modes, using electromagnetic force to switch airflow directions.

2 way soleniod:Designed for fluid on/off control with NO/NC options, this compact electronic solenoid valve suits low-flow applications like washing machine inlet valves and irrigation systems

3 way solenoid:This three-port valve can switch fluid paths or mix/divert media, available in normally open, normally closed, or universal types,

They are all belong to solenoid controlled valve types,but they have different functions in different industries.

Way: The number of internal flow passages in solenoid valves, determining how many paths the airflow can pass through.

The 2-way solenoid valve has a simple structure with two ports and two positions, primarily used for on/off control of A mixture of gases, liquids, and vapors. It features fast response and compact size, making it suitable for frequent switching applications. Common types include normally closed and normally open, In addition, there are also 3-way and 5-way valves, which are widely used in fluid systems across Low pressure to high pressure ranges and high temperature environment.Look this article earn more information about valves'type and their application.

Position: It indicates the number of different positions the valve spool can switch to.

Simply put, a 2-position electric valve has only two states: open and closed. A 3-position valve adds a middle position state. The more positions a valve has, the more airflow states it can achieve, allowing it to meet more diverse operating requirements.Both different types of Electromagnetic valve have different ways and positions, and can achieve complex fluid control capabilities.

We all knoew that the solenoid valve has three control types: Direct Acting, Pilot Operated, and Servo-Assisted.

The solenoid valve's technical parameters as the following table. Understanding more about the attribute parameters can help you apply them more reasonably in system.

| Parameter | Electromagnetic valve |

| Control Type | Direct Acting / Pilot Operated / Servo-Assisted |

| Port Size | G1/8", G1/4", G3/8", G1/2", G3/4", G1", G2" |

| Operating Pressure | 0.2 – 10 bar |

| Pilot Pressure | ≥ 0.5 bar |

| Working Medium | Air, Water, Light Oil, Inert Gas, Steam |

| Ambient Temperature | -10°C to +50°C |

| Operating Temperature | -10°C to +80°C |

| Coil Voltage Options | 12V DC, 24V DC, 24V AC, 110V AC, 220V AC |

Solenoid valve is all electrically driven and controlled, So how is its electromagnetic coil specifically controlled?How does it work?

The following is a comparison of the operation of two types of solenoid valve, which will give you a certain understanding of the diverse working methods of solenoid valves.

Working principle of 2-Way solenoid valve:

The 2-way solenoid valve used for controlling mixed media has a simple structure and directly controls the on-off of the medium. Inside, there is a solenoid coil that generates a magnetic field when energized, driving the plunger to move up and down, thereby opening or closing the fluid passage between the two ports.

Working principle of pneumatic solenoid valve:

A pneumatic solenoid valve is controlled through a combination of electrical and pneumatic signals, a pilot-operated mechanism acts firstly and then drive the main valve core to control the medium flow rate. It is designed for applications involving large flow rates, high pressure, and complex multi-position switching. For detailed information on the operate process, please refer to our technical blog.

No matter what type of electric flow control valve it is,to ensure better performance or work smoothly, it is necessary to carefully check the solenoid valve before use.

For more detailed inquiries or specific air operated valve actuators or technology solutions, reach out to Fokca which is global Pneumatic valves manufacturer and supplier for expert advice and tailored recommendations.You can contact us directly to obtain the latest product prices and catalog information.

FOKCA ©1998-2025 All Rights Reserved Sitemap