Aug 20, 2025

Diaphragm valves are a type of automated mechanical valve that can be driven by various actuators. Their primary operating mechanism is the control of fluid flow passage through the opening between the diaphragm and the valve seat. The long service life of diaphragm valves, the extended maintenance intervals for their working components, and their suitability for food-grade applications are all attributed to the unique design and material selection of the diaphragm. In the following sections, I will focus on the diaphragm's structural design, material selection, maintenance, and care.

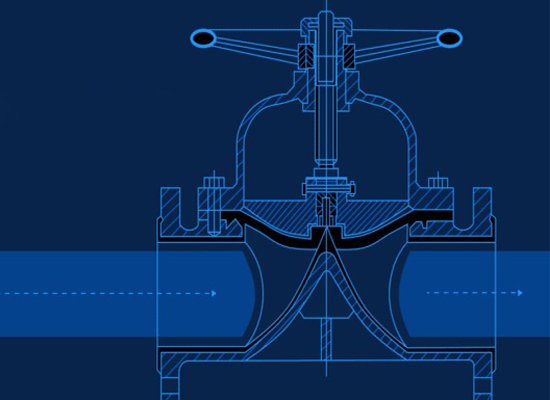

The position of the diaphragm is shown in the figure below.Browse our diaphragm valve products online.

The diaphragm is typically made of a flexible elastomer, allowing it to move up and down or flex within the valve body and is replaceable.

Corrosion-resistant, suitable for a wide temperature range, and suitable for use in the food industry.

Good sealing, no leakage, and capable of passing viscous media.

Long service life, maintenance-free, and suitable for a wide range of industries.

The diaphragm of a diaphragm valve, made from flexible materials, offers advantages such as leak prevention and easy maintenance, thanks to its structural design as follows:

Diaphragms made from flexible materials feature corrosion resistance, a wide operating temperature range, and food-grade compatibility. These advantages come from the careful material selection as outlined below:

The thickness of the diaphragm depends on the valve size, fluid pressure, and elastic modulus of the material.

Too thin → easy to rupture

Too thick → increases actuation force and wastes energy

Therefore, diaphragm thickness must be determined by all three factors and considered both during design and later replacement or maintenance.

To adapt to fluid flow conditions, diaphragms are typically designed in shapes such as flat, corrugated, or composite structures:

Flat Diaphragm: Made from a single layer of flexible material, flat and smooth; suitable for clean fluids with low corrosion and low viscosity.

Corrugated Diaphragm: Features corrugations or folds that allow elastic deformation; suitable for high-temperature fluids with medium corrosion and viscosity, also provides flow regulation.

Composite Diaphragm: Commonly rubber + PTFE, combining the strengths of flat and corrugated types; offers strength and durability, suitable for highly corrosive and high-temperature fluids, though not ideal for extremely low-temperature applications.

The choice and processing of materials directly affect diaphragm performance, including elastic modulus, yield strength, tensile strength, and chemical resistance.

Select materials with adequate yield and tensile strength but moderate elasticity.

For acid/alkali resistance: PTFE, FEP, CR (chloroprene rubber), EPDM.

For organic solvents: FKM (fluoroelastomer), PTFE.

For high temperature: PTFE.

For low temperature: silicone.

For extended service life: reinforced rubber or composite structures.

The diaphragm edge is clamped evenly between the valve body and the bonnet. Proper design ensures uniform stress distribution and reliable sealing.

Uniform Clamping: Prevents leakage and ensures long service life.

Multiple Fixing Points: Facilitates easy disassembly and replacement.

Support Structures:

Flat support → prevents warping and folding

Annular or raised support → disperses stress evenly

Multi-layer composite support → ensures balanced stress across layers and prevents delamination

A well-designed fixation and support structure holds the diaphragm “in the correct position,” distributing stress uniformly and reducing the risk of warping, wrinkling, or fatigue failure.

Leakage inspection

Valve opening/closing state monitoring

Diaphragm wear or rupture detection

Actuator malfunction checks

Regular diaphragm replacement

Cleaning and sterilization

Lubrication and anti-corrosion treatment

Standardized operation practices

This article has introduced the design and material aspects of diaphragms in diaphragm valves, aiming to provide practical guidance for operation and maintenance. The diaphragm is the core component of diaphragm valves and plays a decisive role in delivering their performance advantages.

For more details, explore our other articles covering the working principles, features, advantages and disadvantages, and applications of diaphragm valves, as well as comparisons with other valve types.

In addition to diaphragm valves, Fokcavalve also offers a wide range of other valve solutions, including angle seat valves, globe valves, axial flow valves, and check valves.

Visit our website for more detailed product information and pricing — or contact us directly!

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap