Dec 09, 2025

When selecting valves for industrial pipelines, many users encounter labels such as DN15, DN25, DN50, or DN100. These codes often appear on ball valves, gate valves, diaphragm valves, globe valves, and various automated valve systems. Although simple, the DN (Nominal Diameter) designation is critical for ensuring proper flow rate, installation compatibility, and system performance. Understanding what DN means—and what changes as DN increases—helps engineers avoid mismatched components and inefficient fluid delivery.

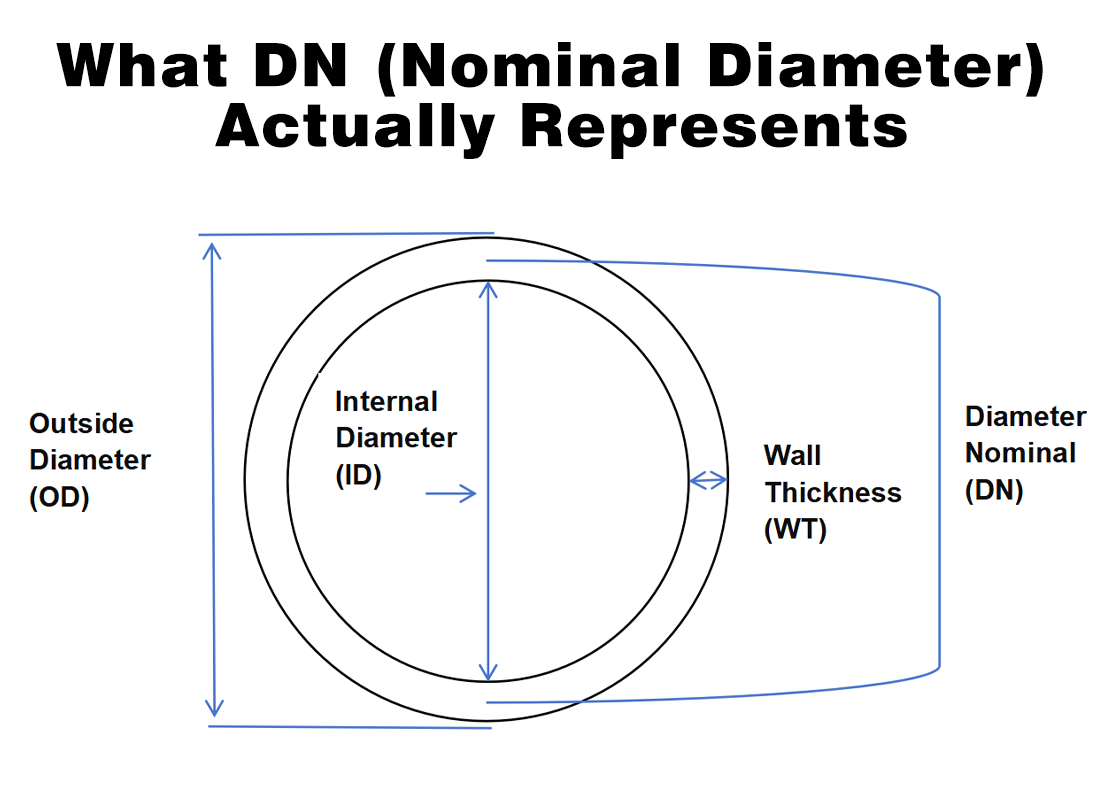

DN stands for Diamètre Nominal, the nominal inner diameter used in global valve and pipe standards. It is not the precise measured diameter but a standardized size reference that ensures compatibility between valves, pipelines, and fittings.

For example:

•DN15 corresponds to approximately 15 mm inner pipeline diameter.

•DN25 corresponds to approximately 25 mm.

•DN50 corresponds to approximately 50 mm.

This allows manufacturers worldwide to produce valves with uniform connection sizes, even if the actual physical dimensions vary slightly depending on material, pressure rating, or wall thickness.

Because many users search DN15 to inches or what size is DN15, here is a quick conversion:

| DN Size | Approx. Inches | Common Name |

|---|---|---|

| DN15 | 1/2 inch | Half-inch valve or pipe |

| DN20 | 3/4 inch | Three-quarter valve |

| DN25 | 1 inch | One-inch valve |

| DN32 | 1¼ inch | One-and-a-quarter valve |

| DN40 | 1½ inch | One-and-a-half valve |

| DN50 | 2 inch | Two-inch valve |

This standardized sizing simplifies selection and ensures that a valve DN15 can reliably fit any DN15 pipe system regardless of manufacturer.

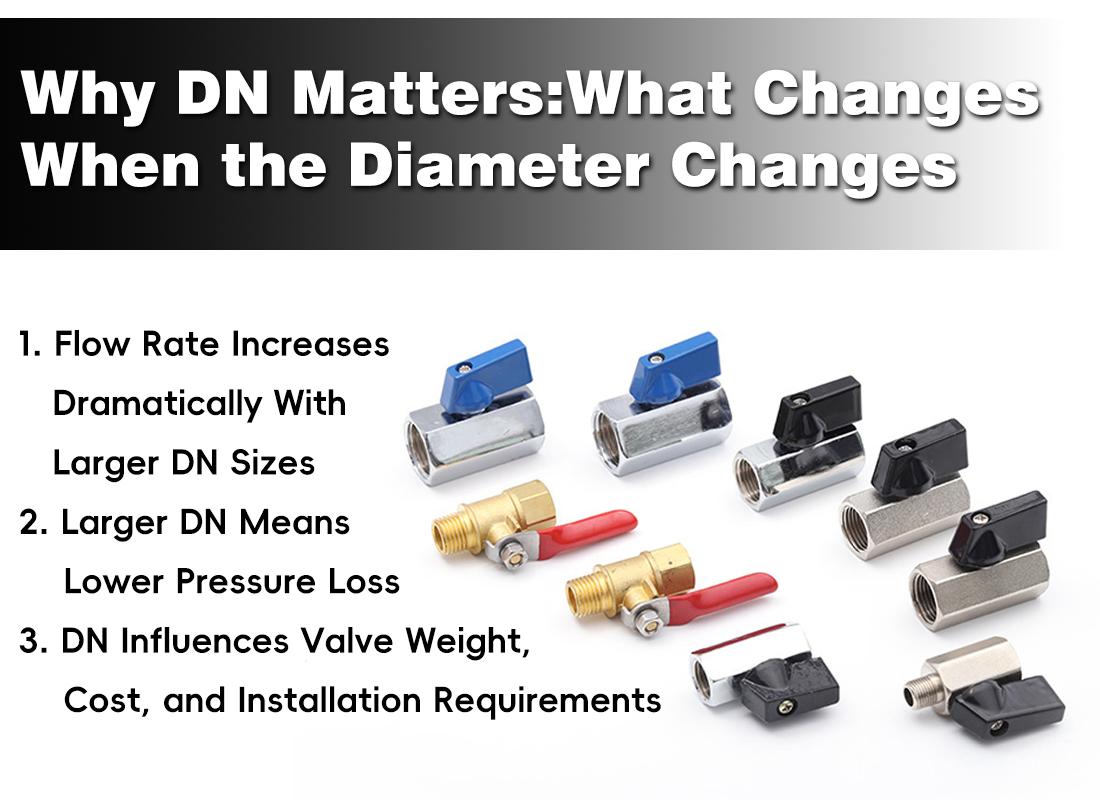

Although DN primarily describes the nominal bore diameter, the size difference directly affects a valve’s performance. Choosing DN15 instead of DN20 or DN25 can change several important features of a fluid system.

A larger diameter allows more liquid or gas to pass through the valve. For example:

A DN15 valve handles small flow volumes, typically used for home water systems, small pneumatic circuits, dosing equipment, or compact automation devices.

A DN25 valve carries much higher flow and is widely used for industrial water distribution, chemical dosing, compressed air networks, and HVAC pipelines.

Because flow rate increases with cross-sectional area, a DN25 valve doesn't provide just 1.7× the flow of DN15—it can allow up to 3× or more, depending on valve type and pressure.

So when users ask: "What does DN25 mean?", It means roughly 1-inch flow size, suitable for medium flow capacity and widely used in industrial systems.

As fluids move through a valve, friction with the internal walls and flow path geometry creates pressure drop. Small-diameter valves—such as DN15—create more frictional resistance, especially when used in long piping systems.

Increasing DN:

•reduces pressure drop

•improves pump efficiency

•stabilizes flow

•prevents cavitation in high-velocity liquid lines

For air systems, a larger DN ensures stronger pneumatic delivery and reduces compressor load.

Choosing DN25 instead of DN15 affects more than flow:

More material → heavier weight

Larger connectors → higher cost

Larger actuators → greater torque and size requirements

Installation space → more clearance needed

In automated systems such as pneumatic actuated ball valves, selecting the correct DN also determines actuator torque size. A DN15 ball valve may require only a compact actuator, while a DN50 valve could need a much larger torque output.

Different industries use DN sizes according to flow needs:

| Application | Typical DN Size | Notes |

|---|---|---|

| Beverage dispensing, small dosing systems | DN15 | Low flow, precise control |

| Industrial water supply, chemical lines | DN25 | Higher flow, common standard |

| Factory air distribution | DN15–DN40 | Depends on equipment demand |

| HVAC chilled water | DN25–DN50 | Balances pressure drop & flow |

| High-capacity pumps | DN50 and above | Ensures stable delivery |

Understanding the relationship between DN and functional need prevents choosing a valve that restricts flow or fails to meet system demand.

When selecting valve sizes, consider the following:

①Required Flow Rate:If accurate volume data is available, flow calculations or Cv/Kv values can determine the correct DN.

②Pipeline Size Compatibility:Valves must match the DN of pipes unless adapters are intentionally used.

③Pressure Drop Limits:High-speed fluid through a DN15 valve may cause noise, vibration, or extra load on pumps or compressors.

④Application Precision:DN15 provides tighter control for dosing and metering applications.

⑤Cost Efficiency:Larger DN sizes raise equipment and actuator cost. Always choose the smallest DN that still meets flow demand.

DN15, DN25, and other DN numbers are not just labels—they determine flow capacity, pressure performance, valve cost, and system compatibility. Whether you are converting DN15 to inches, evaluating what size DN15 is, or determining what DN25 means, understanding nominal diameter ensures the right valve is selected for your application. Getting DN right improves efficiency, reduces system wear, and helps every component work together seamlessly.

If you need any types of valves, you can contact us directly.

(FK9025)

Valve Freezing Prevention Tips for Winter Maintenance

Valve Freezing Prevention Tips for Winter Maintenance

Direct Acting Solenoid Valve or Pilot-Operated?Technical Comparison and Selection Guide

Direct Acting Solenoid Valve or Pilot-Operated?Technical Comparison and Selection Guide

PA66 Explained:Why PA66 Is Widely Used in Valve Actuators

PA66 Explained:Why PA66 Is Widely Used in Valve Actuators

Valve DN Explained:What Size Is DN15, DN20, DN25 and How to Choose?

Valve DN Explained:What Size Is DN15, DN20, DN25 and How to Choose?

Pneumatic Ball Valves Explained: How It Works, Valve Types, and Key Selection Factors

Pneumatic Ball Valves Explained: How It Works, Valve Types, and Key Selection Factors

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap