Dec 08, 2025

In modern automation systems, the pneumatic ball valve has become one of the most widely used flow-control components. It combines a pneumatic actuator with a ball valve body, using compressed air to open and close the valve. Compared with manual or electric actuators, pneumatic drive systems offer faster response, high reliability, and excellent safety, making them ideal for frequent-cycle applications and environments requiring strict protection.

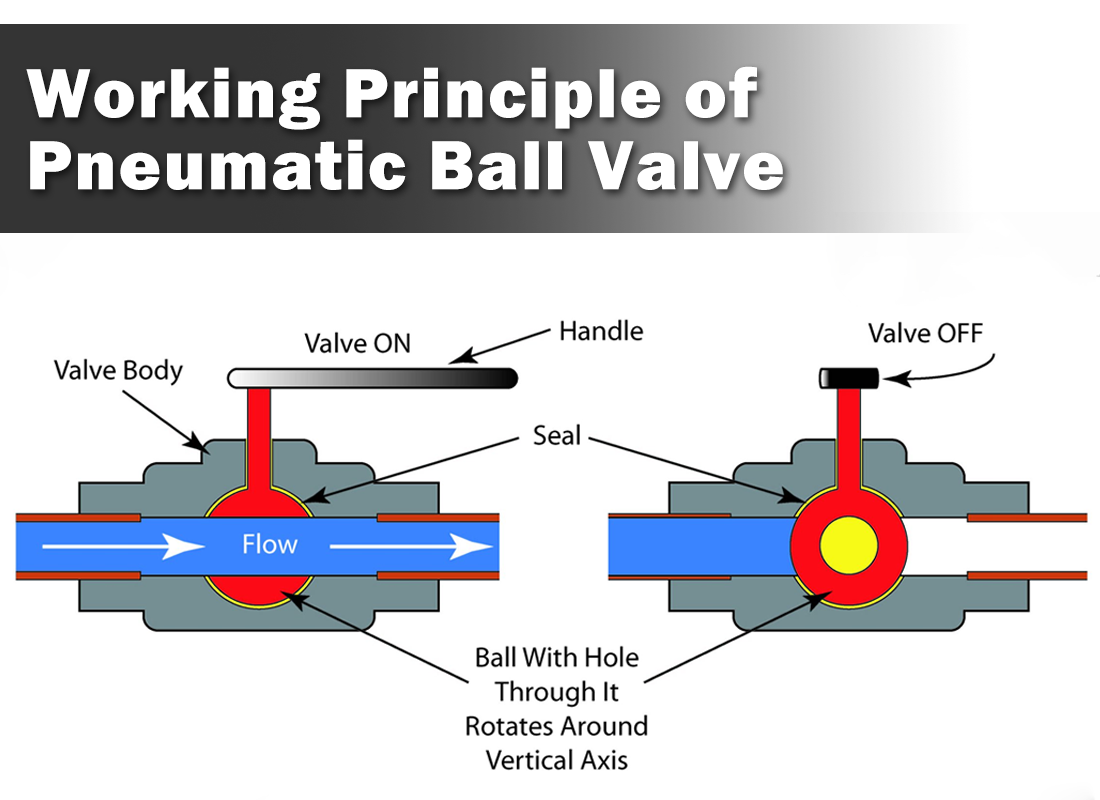

A complete pneumatic actuated ball valve consists of two key parts:

①the pneumatic actuator, which outputs torque

②the ball valve body, which contacts the medium and performs the shutoff or switching action

When compressed air enters the actuator chambers, pistons move and drive the ball to rotate 90° through a rack-and-pinion or crank mechanism. This short-stroke rotary motion ensures rapid switching and stable operation.

For systems requiring automatic safety shutoff, single-acting actuators use air to open and springs to automatically return the valve to a fail-safe position. Double-acting actuators provide bidirectional torque via air pressure on both sides, making them suitable for larger diameters and high-pressure applications. Engineers typically evaluate safety requirements, available air pressure, and operating frequency when choosing the actuator type.

To help engineers quickly identify the correct configuration for their system design, the following table compares the structural and functional differences among 2-way, 3-way, and 4-way pneumatic ball valves.

| Valve Type | Flow Paths | Typical Port Design | Main Applications | Advantages |

|---|---|---|---|---|

| 2-Way Pneumatic Ball Valve | Straight-through (ON/OFF) | 2 ports (inlet + outlet) | General shut-off, isolation, process switching | Simple structure, low cost, minimal flow resistance |

| 3-Way Pneumatic Ball Valve | L-port or T-port | 3 ports | Mixing, diverting, pipeline switching | One valve performs multiple functions, reduces piping complexity |

| 4-Way Pneumatic Ball Valve | Cross or X-path | 4 ports | Complex flow switching, directional control | Can switch multiple flow directions; used in special process systems |

This table helps clarify how each valve structure supports different flow-control strategies, enabling engineers to match the pneumatic actuated ball valve to their specific automation requirements.

Thanks to fast response and long-term durability, the pneumatic actuated ball valve plays an essential role across many industries:

•Food & Beverage: For CIP cleaning, drinking water distribution, beer transfer, and hygienic systems using stainless steel and PTFE seats.

•Water Treatment & Environmental Systems: Used in pump stations, filtration systems, and aeration processes; suitable for humid or outdoor environments.

•Chemical & Pharmaceutical: Utilizes corrosion-resistant materials and explosion-proof actuators for high-risk conditions.

•Machinery & Automated Production Lines: Works seamlessly with PLCs, solenoid valves, and sensors for precise flow control.

These use cases demonstrate the valve’s high speed, reliability, and suitability for repeated cycling.

The widespread adoption of the pneumatic ball valve stems from several significant benefits:

•Fast operation: Full opening or closing typically occurs within 0.3–1 second.

•High safety level: No electrical spark, suitable for flammable or explosive environments.

•Simple, durable structure: Minimal wear between the ball and seats ensures long-term tight sealing.

•Strong adaptability: Capable of handling gas, water, oils, and mildly corrosive fluids.

Compared with electric ball valves, pneumatic versions perform better in low-temperature, high-frequency, and harsh environments.

For stable long-term performance, engineers should evaluate the following:

Valve body material: Stainless steel, PVC, carbon steel, etc., depending on acidity, corrosion, and temperature.

Actuator type: Single-acting for safety-critical systems, double-acting for high torque and large valves.

Seat/seal material: PTFE, RTFE, PPL, and others depending on temperature and chemical resistance.

Connection type: Flanged, threaded, tri-clamp, or welded depending on piping design.

Operating frequency: High-cycle applications require stronger bearings and durable seat materials.

Proper selection significantly reduces maintenance and improves system efficiency.

As a key component in industrial automation, the pneumatic ball valve offers exceptional efficiency, safety, and reliability. Whether in two-way, three-way, or four-way configurations, it provides accurate flow control for complex systems. With correct selection and application, pneumatic ball valves can deliver long service life and optimum performance in a wide range of industries.

If you need any type of ball valves, you can contact us directly.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap