Dec 10, 2025

In the field of pneumatic and fluid control, the fundamental difference between a pilot-operated solenoid valve and a direct acting solenoid valve often goes unnoticed, yet it plays a decisive role in system stability, service life, and energy consumption. During equipment maintenance, many users focus only on port size or thread type while ignoring the internal driving mechanism, which can lead to valve stalling, overheating, or complete failure.

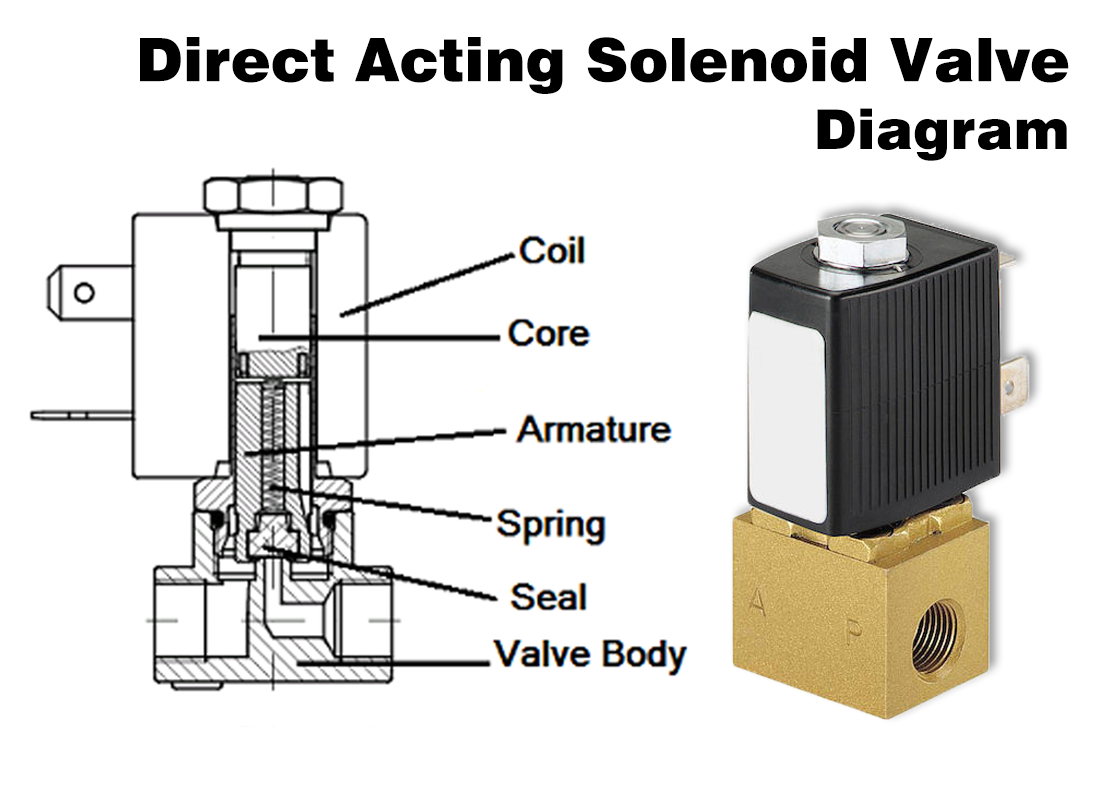

In a direct acting structure, the magnetic field generated by the coil directly pushes or pulls the valve core, and all driving force comes from the electromagnetic coil itself. Because this type of direct acting solenoid valve does not rely on upstream pressure or pressure differentials, it performs well in equipment operating at extremely low or even zero start-up pressure.

When the coil is energized, magnetic force acts immediately on the plunger, moving the valve core and switching the flow path. The structure is compact, reaction time is fast, and it works reliably in small orifices (≤DN10) and low-pressure ranges (≤0.7 MPa). Common applications include laboratory benches, miniature grippers, and analytical instruments.

However, because the coil must overcome spring force and fluid resistance directly, heat generation is more noticeable, and energy consumption increases. In high-frequency switching systems or long-term energized situations, heat control and material durability become particularly important.

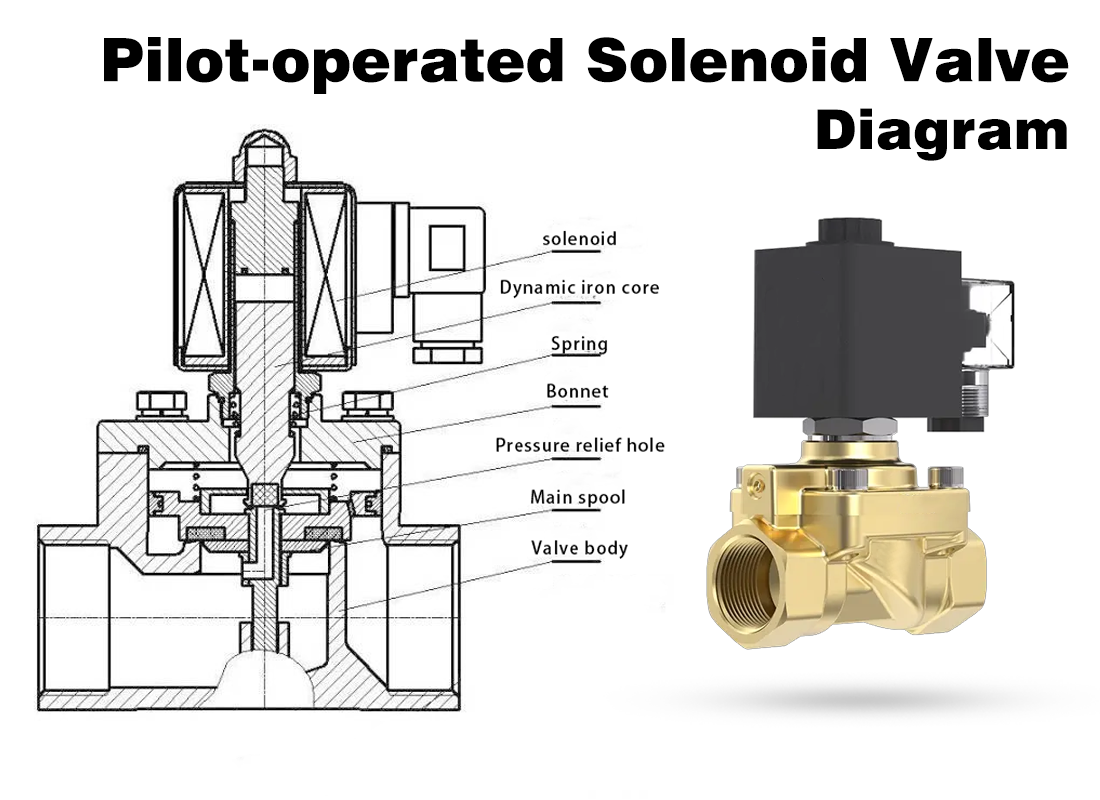

A pilot-operated solenoid valve uses the coil differently—more like a “trigger switch.” When the coil is energized, the magnetic force only needs to open a small pilot orifice. Once the pilot hole opens, the system’s own compressed air pushes a diaphragm or piston to move the main valve element.

The coil no longer needs to provide full driving force. As a result, these valves perform extremely well in larger orifices (DN15–DN50) and medium-to-high-pressure systems, and coil temperature remains low. This type of pilot solenoid valve is widely used on automatic production lines, air distribution systems, and material-handling machinery where high flow capacity must remain stable.

When the system has sufficient upstream pressure, a pilot-operated solenoid valve can achieve much higher efficiency. Coil power is often just one-third to one-fifth of a direct operated design. For systems requiring long-term energized holding, this difference directly influences operating costs and valve lifespan.

The fundamental distinction—direct acting valves rely on magnetic force, while pilot-operated valves rely on air pressure—creates a clear application boundary.

① Start-up pressure is extremely low or absent

② Small orifice, low flow

③ Fast switching frequency

④ Compact structure required

⑤ Instrumentation and analytical equipment with micro air passages

In these systems, direct acting solenoid valves ensure each actuation is independent from pressure fluctuations.

① System has stable working pressure

② High flow rate required

③ Orifice size ≥DN15

④ Low temperature rise needed or long energizing periods

⑤ Compressed air systems, packaging lines, pneumatic logic circuits

With sufficient supply pressure, pilot-operated solenoid valves achieve greater force with minimal energy consumption.

| Feature | Direct Acting Solenoid Valve | Pilot-Operated Solenoid Valve |

|---|---|---|

| Driving force | Electromagnetic force | Compressed air pressure |

| Start-up pressure | Zero-pressure capable | Requires minimum pressure |

| Suitable orifice size | Small (DN1–DN10) | Medium–large (DN15–DN50+) |

| Response | Very fast | Slightly slower but stable |

| Energy consumption | Higher | Lower |

| Coil temperature | Noticeable rise | Mild rise |

| Typical applications | Instruments, micro devices | Production lines, air systems |

The comparison is based on industry experience and common characteristics of 2/2 and 3/2 pneumatic solenoid valve series.

Choosing a valve involves more than just matching port size; pressure, flow rate, installation direction, and switching frequency all influence performance. For low-pressure start-up applications such as small fixtures or laboratory gas paths, a direct operated structure provides more reliability. For stable airflow, high-volume switching, or continuous energizing, a pilot-operated solenoid valve significantly reduces energy load and improves durability.

If you need any types of solenoid valves, you can contact us directly.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap