Dec 08, 2025

In modern industrial automation, the reliability of valve operation often determines the overall safety and efficiency of a production line. Among all actuation methods, a pneumatic actuator stands out for its simple construction, fast response, and low maintenance requirements. During equipment selection, engineers typically need to decide between a single acting actuator and a double acting actuator, and this choice directly influences system safety, energy consumption, and long-term performance.

In demanding or safety-critical environments, a single acting actuator offers an advantage that other actuation methods cannot replace. The internal spring package allows the actuator to return to a predefined safe position—open or closed—when the air supply or control signal fails.

This fail-safe capability makes the actuator function as the “final layer of protection.” It is widely used in steam systems, natural gas lines, chemical processing, food production, and pharmaceutical pipelines. Even if the air supply is lost, the valve automatically returns to its safest position, preventing leakage, pressure spikes, contamination, or product loss.

When selecting a pneumatic valve actuator, if the installation must meet mandatory fail-safe requirements (Must Close or Must Open during failure), a single acting model becomes the clear choice.

Typical applications:

Steam distribution, gas safety shutoff, chemical dosing lines, food and beverage CIP/SIP systems.

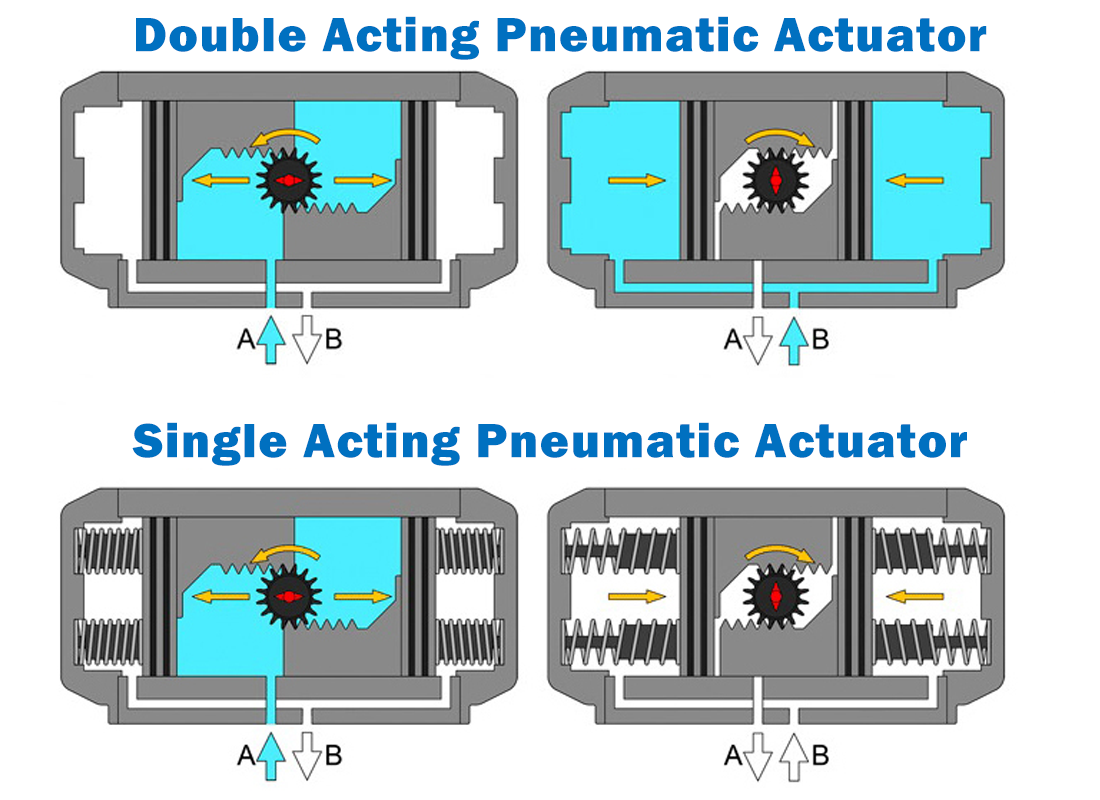

A double acting actuator uses air pressure for both opening and closing. Without the need to overcome spring resistance, it delivers significantly higher output torque for the same body size. This makes it ideal for ball valves and butterfly valves with higher operating resistance—especially in large diameters or systems conveying viscous media.

The balanced air distribution inside the actuator also enables quicker actuation and more precise control. For this reason, many pneumatic actuated ball valve systems adopt double acting designs to achieve consistent, efficient performance.

Furthermore, the absence of springs eliminates fatigue failures, making double acting actuators more suitable for high-frequency cycling.

Choosing between single and double acting designs requires evaluating safety, torque needs, valve characteristics, and process conditions. Below are the most important factors engineers consider when selecting a pneumatic actuator.

If the system demands Must Close or Must Open behavior during air supply failure, a single acting design offers superior reliability due to its fail-safe spring mechanism.

Best choice: single acting actuator

Applications: steam, fuel gas, hazardous chemical lines, food and pharmaceutical processes.

The greater the valve’s operating resistance, the more suitable a double acting actuator becomes.

High-pressure, large-diameter, and viscous media lines often require this design because it delivers higher torque without spring limitations.

Best choice: double acting actuator

Applications: large butterfly valves, high-pressure ball valves, slurry pipelines, oilfield equipment.

High-frequency actuation exposes springs to rapid fatigue. Therefore, fast-cycle automation systems typically prefer double acting designs with balanced air control and low wear.

Typical industries: filling machinery, packaging equipment, quick-switch valve manifolds.

Single acting actuators may consume less air since only one direction requires air pressure while the return stroke relies on spring force.

Double acting actuators require air for both directions, resulting in higher consumption. However, they are less sensitive to air impurities and moisture, which can affect spring chambers.

Single acting actuators have more complex internal construction, making them slightly more expensive.

Double acting actuators are simpler, more economical, and easier to maintain—especially in high-cycle operations.

Core Difference Table (Selection Guide)

| Feature | Single Acting Actuator | Double Acting Actuator |

|---|---|---|

| Fail-safe ability | Automatic spring return | No automatic fail-safe |

| Output torque | Slightly lower | Higher torque |

| Safety level | Higher | Dependent on external protection |

| Air consumption | Lower | Higher (air used in both strokes) |

| Cycle frequency | Less ideal for high frequency | Excellent for high-frequency cycling |

| Cost | Slightly higher | Lower overall |

You can quickly determine the suitable actuator type based on the following principles:

Safety-first system? → Choose Single Acting

High torque requirement? → Choose Double Acting

High-frequency operation? → Choose Double Acting

Regulations require fail-safe? → Single Acting

Limited budget but large torque demand? → Double Acting

When these factors conflict, system safety level should always be the primary consideration, followed by efficiency and cost.

Single acting and double acting actuators are not competing technologies; they are tailored solutions for different process scenarios.

Single acting actuators deliver ultimate fail-safe security, while double acting actuators offer higher power and faster performance.

By evaluating valve characteristics, process needs, and control strategy, engineers can choose the most reliable pneumatic actuator for their systems.If you need any type of actuators, you can contact us directly.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

Nov 21, 2025 Blog

How to determine valve seat angleFOKCA ©1998-2025 All Rights Reserved Sitemap