Sep 05, 2025

A globe valve is a type of linear motion valve that can both control the on/off state of fluid in a pipeline and regulate the flow rate of the medium.

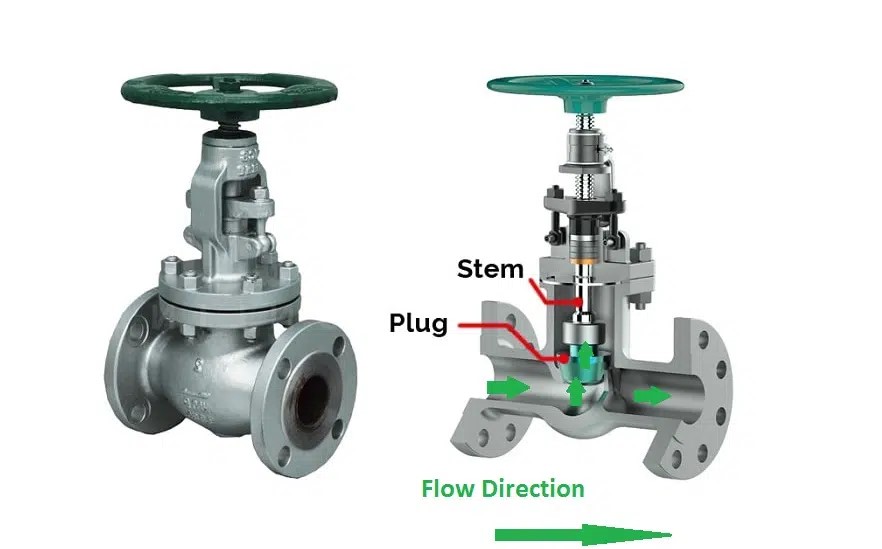

The name derives from its spherical valve body, which contains a movable disc or plug mechanism. This mechanism controls fluid flow by closing, opening, or partially obstructing the flow passage of the valve.

Globe valves come in various types and are widely used flow control devices in a range of industrial applications to regulate the flow of fluids such as liquids, gases, and steam in pipeline systems. Thanks to their unique structural characteristics and reliable performance, globe valves are highly popular in industries such as oil and gas, power generation, chemical processing, and water treatment.

Actuation Methods of Globe Valves:

Globe control valvesare operated by different types of actuators that drive the valve stem to lift or lower the valve core relative to the valve seat:

Manual Operation: A handwheel device is used to drive linear up-and-down movement of the valve core via rotation of the threaded valve stem.

Automatic Operation: Electric or pneumatic actuators are used to automatically drive the linear motion of the valve stem.

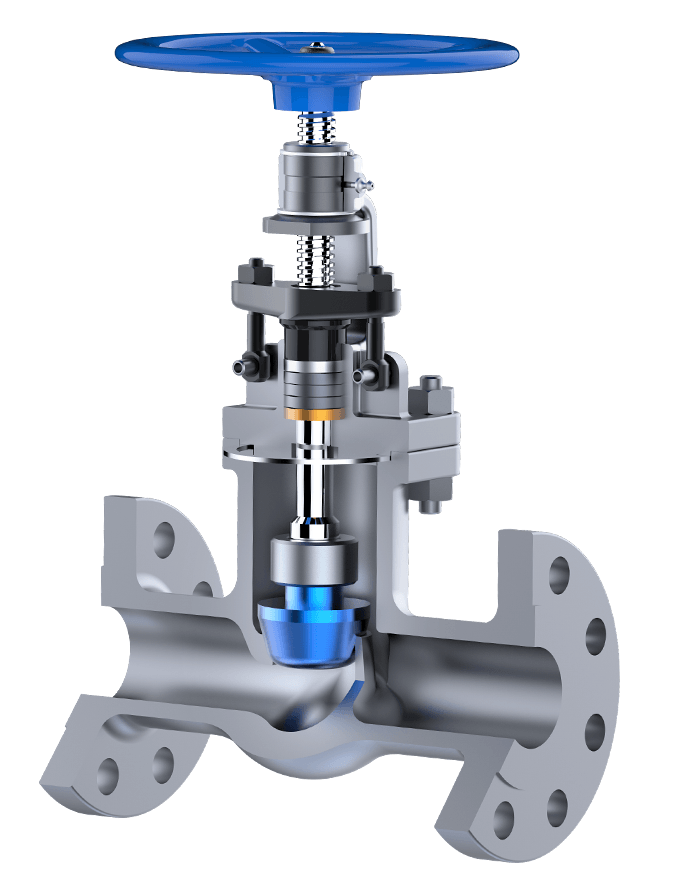

A globe valve derives its name from its spherical body, which contains a movable metal disc (also referred to as a plug), a fixed metal seat, and a vertically moving stem. The stem connects the disc to an external handwheel or actuator. When the handwheel is turned or the actuator is engaged, the stem and disc are raised or lowered against the seat, thereby controlling the flow and pressure.

The core structures of globe control valve:

Body: The main structure of the valve, typically made of cast iron, carbon steel, stainless steel, or alloy materials.

Bonnet: The top part of the valve, which houses the stem and packing.

Stem: A threaded rod connected to the disc or plug, used to control valve movement.

Disc or Plug: The movable component that regulates flow by obstructing the flow path.

Seat: The stationary part against which the disc or plug seals to prevent fluid flow.

Handwheel or Actuator: The manual or automatic mechanism used to operate the valve.

The metal valve core and seat achieve a hard seal, making them suitable for high-pressure and high-flow regulation and control. However, they are prone to seal damage when handling corrosive, granular, or viscous media.

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Apr 22, 2025 Blog

Pneumatic Globe Control Valve

Mar 20, 2025 Blog

Butterfly Valve vs Pneumatic Globe Control Valve

Mar 06, 2025 Blog

Pneumatic Globe Control Valve: An OverviewFOKCA ©1998-2025 All Rights Reserved Sitemap