Feb 05, 2026

The 3 way solenoid valve is widely used in vacuum gripping, evacuation, and vacuum break control. Unlike compressed-air applications, vacuum conditions are extremely sensitive to leakage, sealing structure, and exhaust routing. Even a minor internal leak can reduce vacuum level and disturb production rhythm.

Vacuum is not simply negative pressure; it is a state with very few gas molecules. In this environment, the contact between seal and body determines whether the system can hold vacuum. A standard 3/2 way solenoid valve that works well in pneumatic circuits may struggle in vacuum because elastomer rebound and micro-gaps become critical.

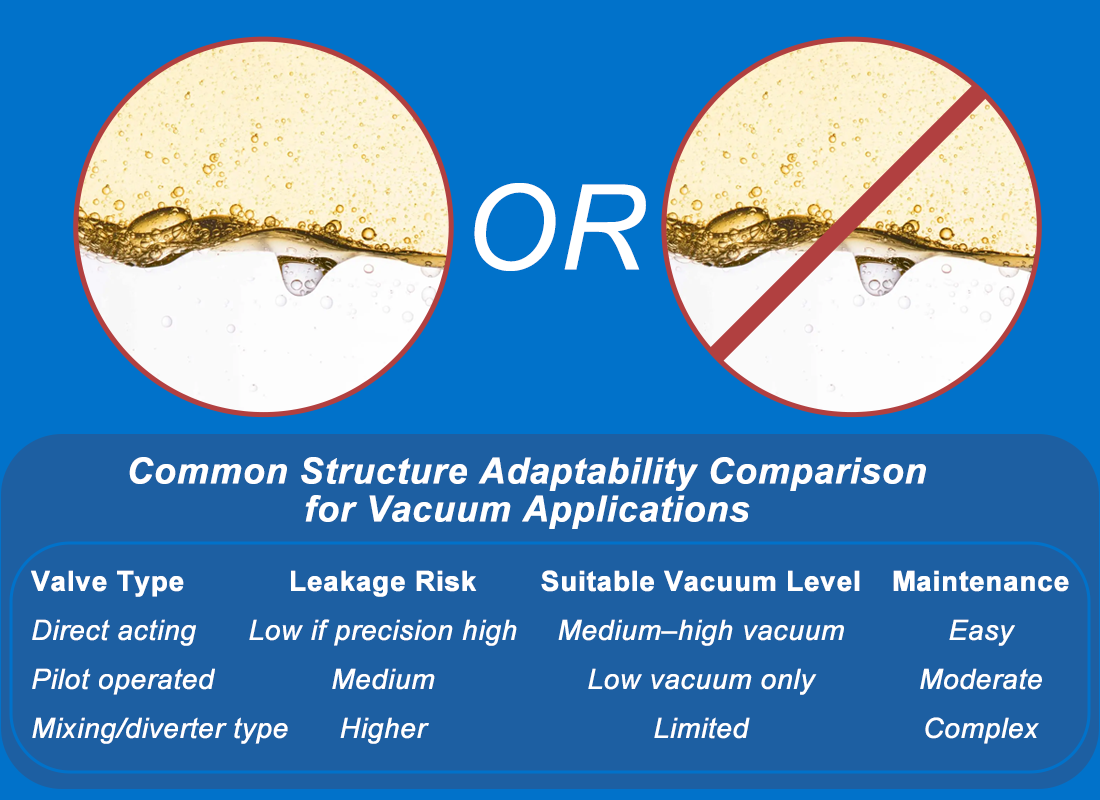

The choice between 3 way direct acting solenoid valve and 3 way pilot operated solenoid valve is important. Direct acting types respond quickly and do not rely on pressure differential, while pilot operated designs may fail to shift when vacuum level is high and supply pressure is low.

In a vacuum circuit, the exhaust port is used to break vacuum. If the exhaust channel is restricted, a temporary closed chamber may form during 3 way solenoid valve switching, slowing recovery. The logic of 3 way normally closed solenoid valve and 3 way normally open solenoid valve must match the piping design; wrong connection can make vacuum impossible to build.

Engineers often choose compact 3 way solenoid valve for small machines, yet compactness means smaller flow passages and greater pressure drop. Placing the valve close to the suction cup and minimizing tubing volume is a practical rule.

Lack of lubrication increases friction of seals. For clean industries, an industrial automation solenoid valve with oil-free treatment is preferred. Mixing types such as 3 way diverter solenoid valve or 3 way mixing solenoid valve should be evaluated carefully because internal cavities may trap contaminants.

When controlling a vacuum cylinder, the 3 way valve for pneumatic cylinder must deliver fast evacuation. A high speed 3 way solenoid valve improves cycle time but requires stable voltage and proper coil voltage 3 way valve selection. Using modular manifold solenoid valves can reduce connection points and leakage risks.

◆ Verify port marks before connecting any exhaust port valve 3 way

◆ Add filtration to protect the spool of solenoid valve 3 way control

◆ Avoid long tubing between valve and vacuum device

◆ For harsh environments, consider DIN-standard DIN connector 3/2 solenoid valve

Vacuum applications reveal weaknesses that are invisible in ordinary pneumatic service. Understanding sealing behavior and flow logic ensures that a 3-way pneumatic solenoid valve performs reliably in demanding systems.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap