Feb 07, 2026

In industrial automation, the pneumatic ball valve controls fluid flow through ball rotation. During opening and closing, the ball can trap medium between itself and the seat, causing temporary local pressure peaks. Although brief, this phenomenon significantly impacts seal wear and seat life.

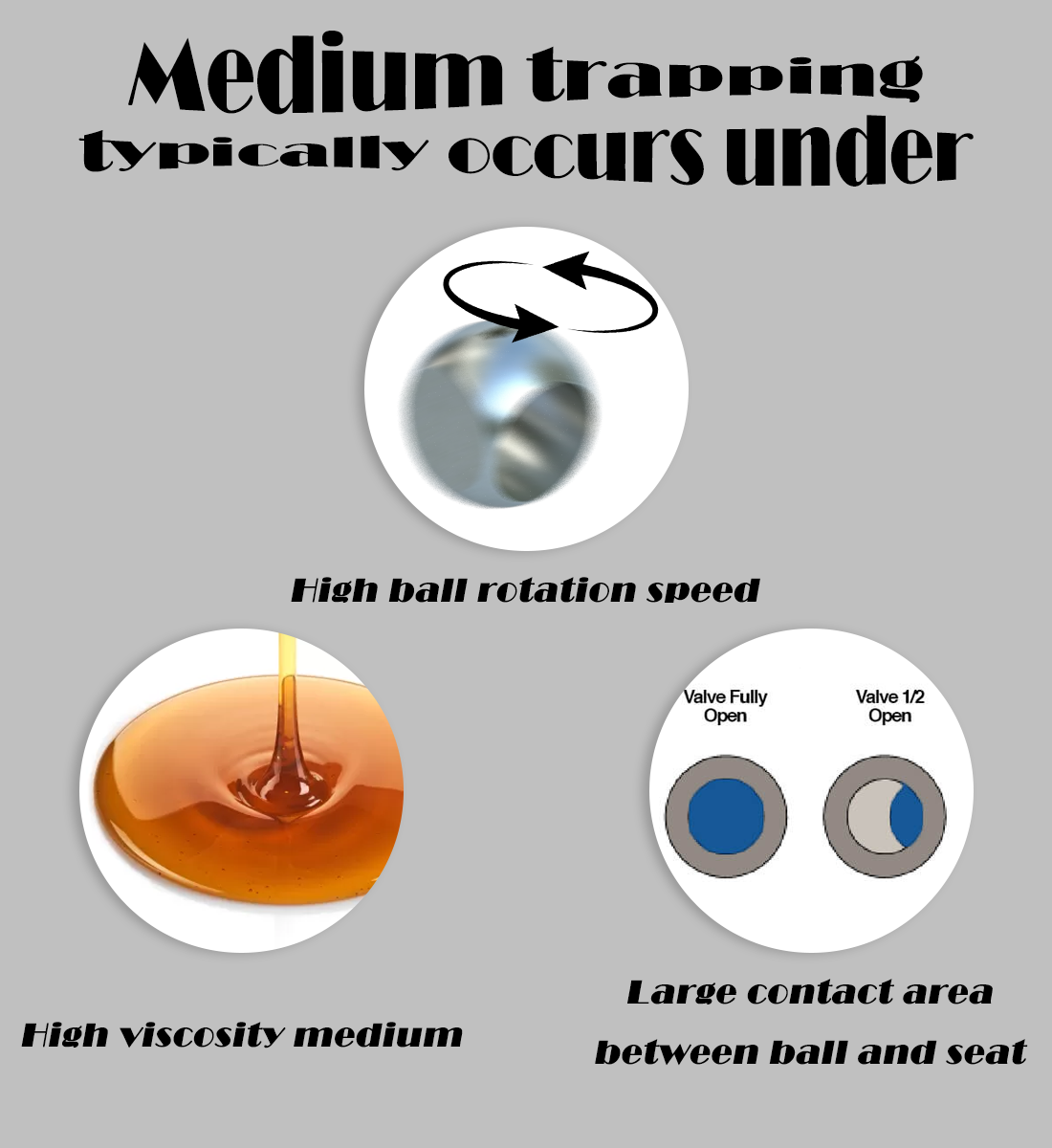

Medium trapping typically occurs under:

① High ball rotation speed – fluid cannot escape the seat gap in time.

② High viscosity medium – oil, slurry, or dense liquid tends to be trapped.

③ Large contact area between ball and seat – in fully closed or partially open positions, medium gets “pinched.”

It is common in pneumatic 2 way ball valve, pneumatic 3 way ball valve, or pneumatic stainless steel ball valve applications.

| Factor | Effect on Ball Valve | Notes |

|---|---|---|

| Ball Rotation Speed | Higher speed → increased medium trapping | Fast actuation valves like air operated ball valve more prone |

| Medium Viscosity | High viscosity → longer retention | Oil, slurry, or high-density fluid |

| Contact Area | Larger sealing surface → higher trapping pressure | Quarter turn pneumatic ball valve geometry matters |

| Valve Type | Direct acting vs pilot operated | Direct acting responds faster, less trapping |

| Actuator Torque | Low torque → incomplete closure | Ensure pneumatic ball valve torque requirement is met |

Trapped medium causes momentary stress, resulting in:

◆ Seal wear – micro-cracks or scratches leading to leakage

◆ Reduced seat life – soft seats wear faster under viscous or particulate media

◆ Increased torque – closure requires higher force, impacting double acting or spring return pneumatic ball valve

◆ Flow fluctuations – temporary spikes during closure

| Impact | Description | Mitigation |

|---|---|---|

| Seal Wear | Micro scratches and stress on sealing surface | Use stainless steel pneumatic ball valve or hard-faced seals |

| Seat Life | Reduced due to trapped medium pressure | Urethane or PTFE seat with abrasion resistance |

| Torque Requirement | Higher torque needed for closure | Verify actuator sizing per pneumatic ball valve torque requirement |

| Flow Performance | Temporary pressure spikes | Adjust actuation speed and consider pneumatic ball valve control system |

To minimize negative effects:

① Control rotation speed – adjust pneumatic ball valve actuator pressure and stroke speed.

② Choose proper seat material – abrasion-resistant PTFE, polyurethane, or hard metal seats.

③ Optimize medium flow path – reduce stagnation and frequency of trapping.

④ Perform regular maintenance – check seat and seal integrity as per pneumatic ball valve maintenance tips.

Proper design and operation ensure reliable long-term performance for pneumatic ball valve for water system, steam, gas, chemical process, or oil & gas automation systems.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Jan 08, 2026 Blog

Why Globe Valves Cannot Fully Replace Ball Valves

FOKCA ©1998-2025 All Rights Reserved Sitemap