Feb 02, 2026

In pneumatic automation, the 3 way solenoid valve offers more functions than a two-way valve, yet the increased number of ports also raises the risk of wrong connection. Many commissioning failures are not related to product quality but to misunderstanding of port identification.

A typical 3/2 way solenoid valve contains a pressure port, a working port and an exhaust port. Markings may appear as P-A-R, 1-2-3 or IN-OUT-EXH depending on the manufacturer. If the exhaust port is connected to the air supply, pressure will escape directly and the actuator cannot build force. When the working port and inlet are reversed, the motion logic of the cylinder becomes opposite, a frequent issue in 3-way pneumatic solenoid valve applications.

◆ Air supply path is interrupted and stroke becomes insufficient

◆ Exhaust channel is blocked, causing slow return

◆ Safety logic of 3 way normally closed solenoid valve or 3 way normally open solenoid valve is reversed

◆ Continuous leakage and abnormal heating appear

A packaging machine once used a 3 way solenoid valves unit with ports mixed during installation. The manipulator failed to return after power loss, and several valves were replaced before the real cause was found.

| Valve Structure | Identification Clarity | Error Risk |

|---|---|---|

| Direct acting 3 way | High | Medium |

| Pilot operated 3 way | Medium | High |

| Diverter/Mixing type | Low | Very High |

The 3 way diverter solenoid valve and 3 way mixing solenoid valve involve more complex internal paths, so misconnection may even cause media backflow. In manifold systems such as modular manifold solenoid valves, shared exhaust ports further increase confusion.

Unlike two-way valves, a 3 way valve automation device must distinguish supply, outlet and exhaust simultaneously. Some brands use numbers on DIN connector 3/2 solenoid valve, others use letters, which may conflict on site. For AC/DC 3 way solenoid valve, coil polarity does not indicate flow direction, misleading many technicians.

Providing a clear diagram for every 3 way valve for pneumatic cylinder is essential. Valves with engraved marks, such as compact 3 way solenoid valve, help installers quickly identify ports. For critical equipment, a feedback-based solenoid valve 3 way control strategy can verify the real flow state.

Understanding the mechanism of 3 way solenoid valve switching is more important than replacing components blindly. Training and standardized documentation should accompany product delivery.

◆ Confirm inlet and exhaust port valve 3 way before piping

◆ Avoid mixing different marking systems on one machine

◆ Use fast response 3 way solenoid valve only after correct routing

◆ Evaluate pilot-operated vs direct acting 3 way valve according to circuit layout

Correct port identification ensures that the industrial automation solenoid valves operate as designed, protecting both equipment and production efficiency.

(FK9025)

System Problems Caused by Incorrect Port Identification of 3 Way Solenoid Valve

System Problems Caused by Incorrect Port Identification of 3 Way Solenoid Valve

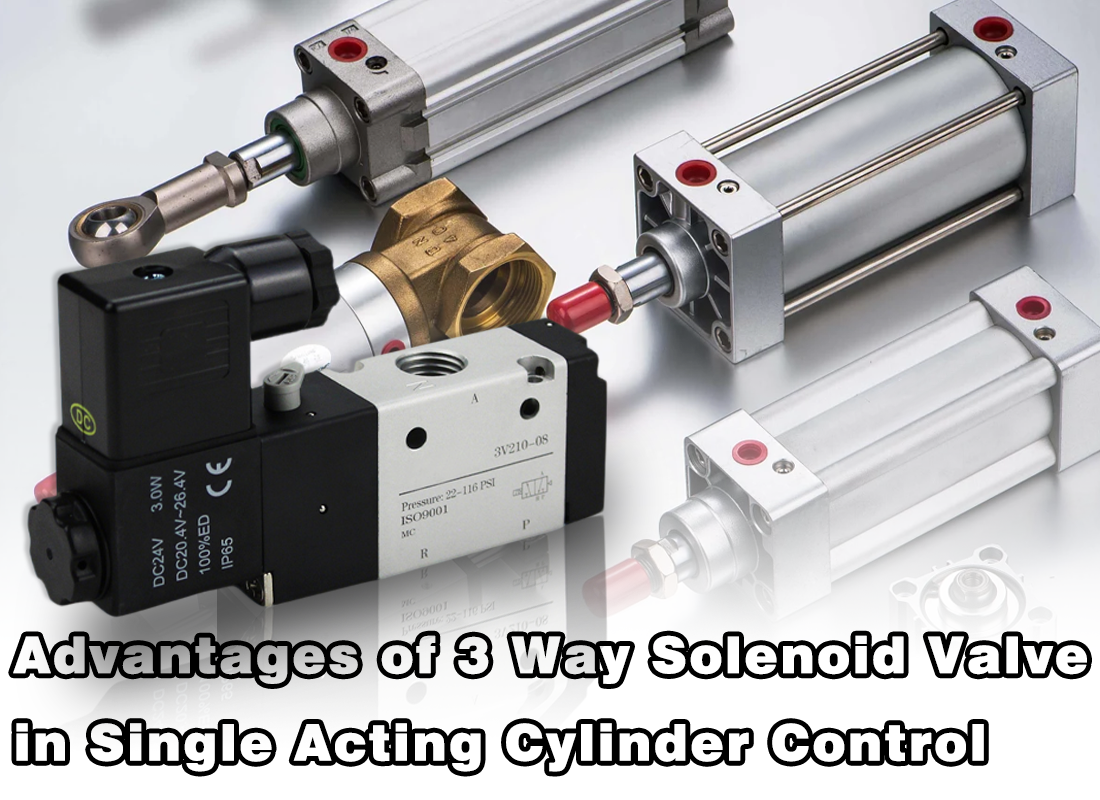

Advantages of 3 Way Solenoid Valve in Single Acting Cylinder Control

Advantages of 3 Way Solenoid Valve in Single Acting Cylinder Control

Supply and Exhaust Logic of Normally Open and Normally Closed 3-Way Solenoid Valves

Supply and Exhaust Logic of Normally Open and Normally Closed 3-Way Solenoid Valves

Application Scenarios of Mixed Flow Path Design in 3-Way Solenoid Valves

Application Scenarios of Mixed Flow Path Design in 3-Way Solenoid Valves

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap