Jan 30, 2026

In many automation systems, a 3 way solenoid valve is not limited to simple supply-and-exhaust functions. Certain designs intentionally use mixed flow paths to switch between different media sources or pressure supplies. While this approach simplifies piping and saves space, it also introduces potential interaction between flow paths that must be carefully managed.

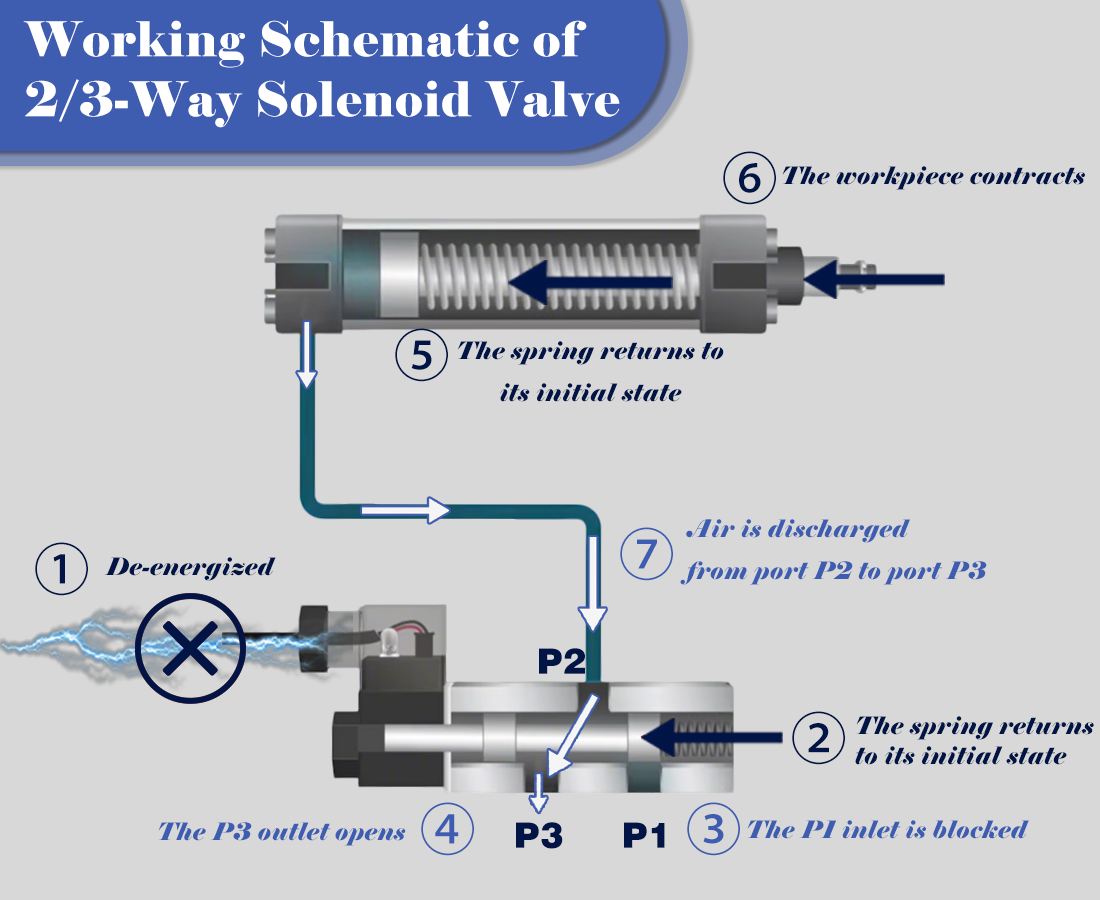

A mixed flow path does not mean that media are blended inside the valve body. Instead, it refers to a configuration where one common port connects alternately to different functional ports. In a typical 3/2 way solenoid valve, the common port switches between pressure and exhaust. In more complex systems, a 3 way mixing solenoid valve or diverter design may connect the same outlet to different supply sources.

This logic is widely used in pneumatic directional control valve systems and compact industrial automation layouts.

Compared with simple on-off valves, mixed flow designs are more sensitive to timing. During 3 way solenoid valve switching, the valve spool passes through a transitional position. If sealing is not fully established, residual pressure or media can briefly migrate into an unintended port.

In high-frequency or fast response 3 way solenoid valve applications, this may lead to actuator hesitation, pressure spikes, or unstable signals—especially in systems controlling pneumatic cylinders or air actuators.

Valve construction plays a decisive role in how well mixed flow paths are controlled. A 3 way direct acting solenoid valve offers fast response but shorter sealing overlap, increasing the chance of transient interference. By contrast, a 3 way pilot operated solenoid valve uses controlled pressure to move the main spool more smoothly, reducing unwanted port interaction.

| Valve Design | Switching Behavior | Flow Path Isolation |

|---|---|---|

| Direct Acting | Instant response | Moderate |

| Pilot Operated | Progressive movement | High |

| Compact 3 Way Solenoid Valve | Space-optimized | Design dependent |

| Modular Manifold Solenoid Valves | Integrated channels | System dependent |

The first step is selecting the correct function. Selecting vs diverting 3 way valves serve different purposes, even if their port counts appear similar. Using the wrong type can unintentionally connect pressure and exhaust paths.

Choosing a normally closed 3 way solenoid valve or normally open 3 way solenoid valve also defines a safe default state, helping prevent interference during power loss or startup.

Even with high-quality industrial automation solenoid valves, poor piping design can amplify residual pressure effects. Long branch lines and oversized internal volumes increase the chance that trapped media will influence the next cycle. Experienced engineers often optimize tubing length and add damping components to stabilize the system.

Control logic should also avoid simultaneous switching of multiple valves whenever possible.

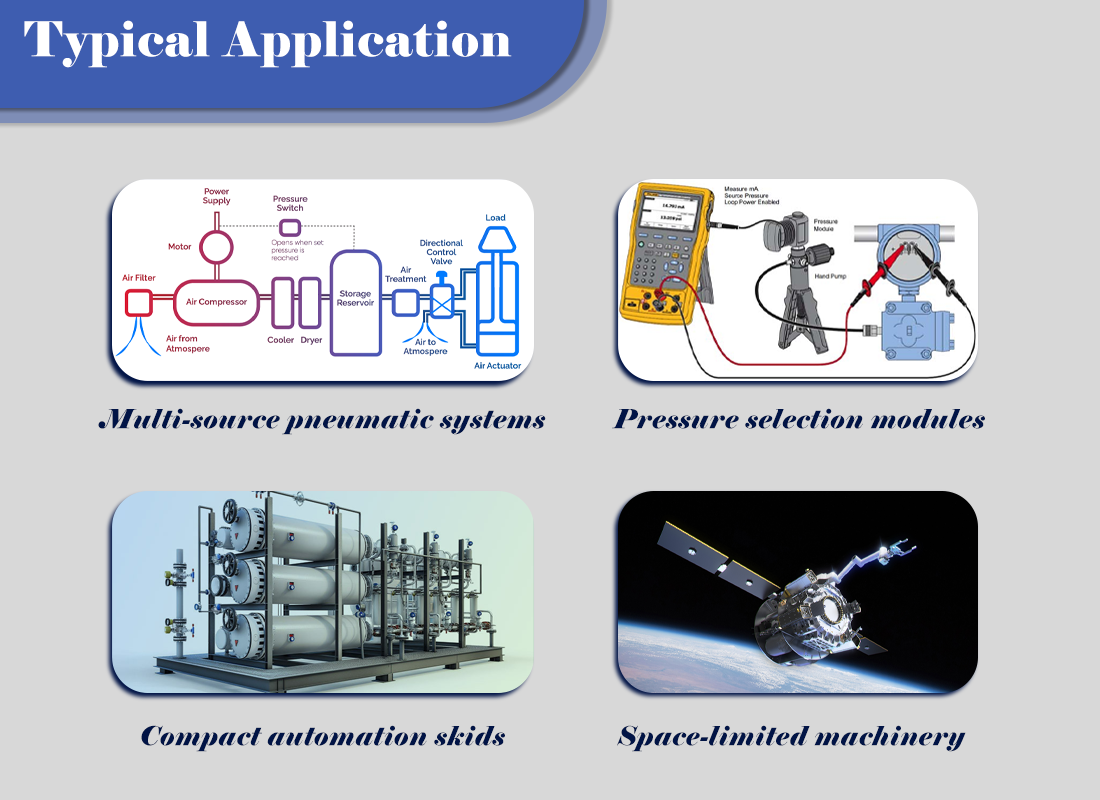

When properly applied, mixed flow designs offer clear benefits. Typical use cases include multi-source pneumatic systems, pressure selection modules, compact automation skids, and space-limited machinery using compact 3 way solenoid valve assemblies.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap