Jan 30, 2026

In pneumatic control systems, a 3 way solenoid valve acts as the breathing point between supply and exhaust. Unlike two-way valves that simply open or close flow, a three-way configuration continuously switches between pressurizing and venting an actuator. The default port connections—especially during power loss—have a direct impact on system safety, stability, and operational behavior.

A typical 3/2 way solenoid valve features three ports: inlet, outlet, and exhaust. At any moment, one path supplies pressure while another releases it. This structure makes 3-way pneumatic solenoid valves a standard choice for pneumatic cylinders, air actuators, and compact automation modules.

From an engineering standpoint, the key question is whether the working port remains pressurized or vents when power is removed. This is where normally closed and normally open designs differ fundamentally.

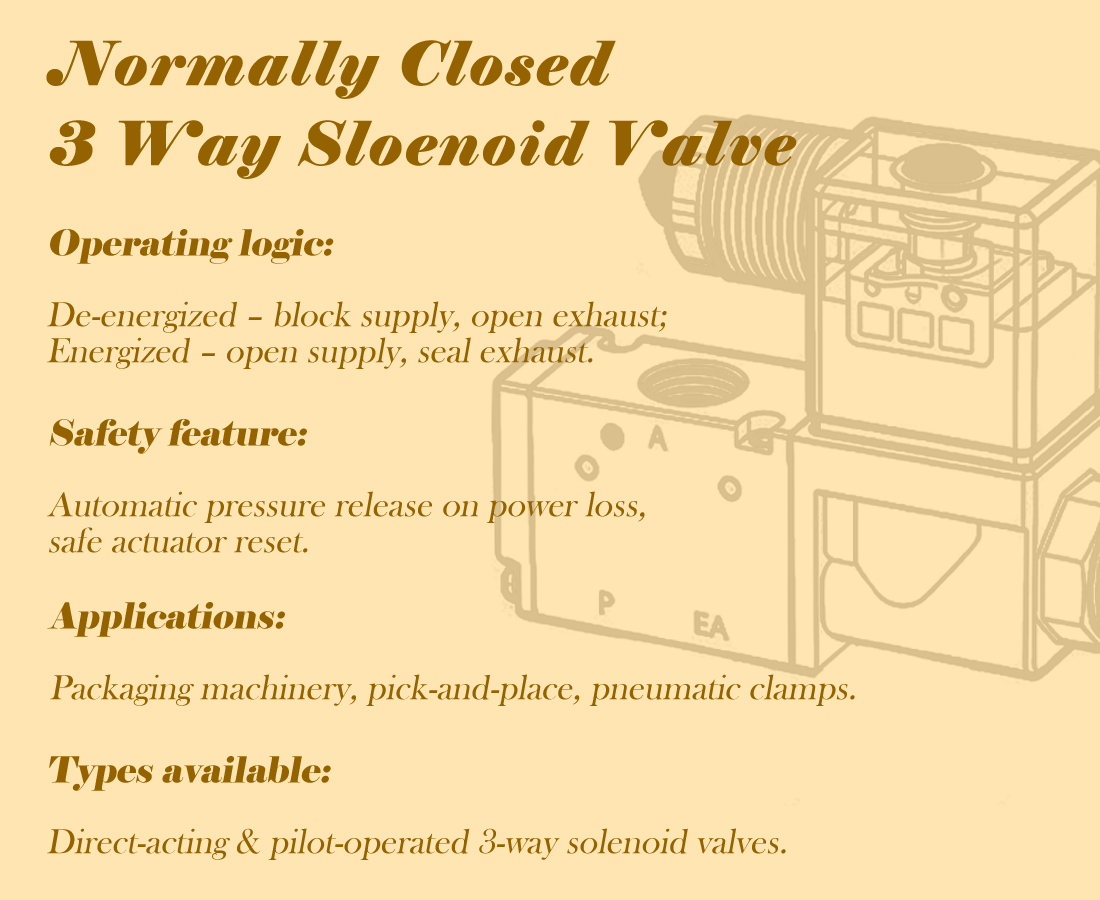

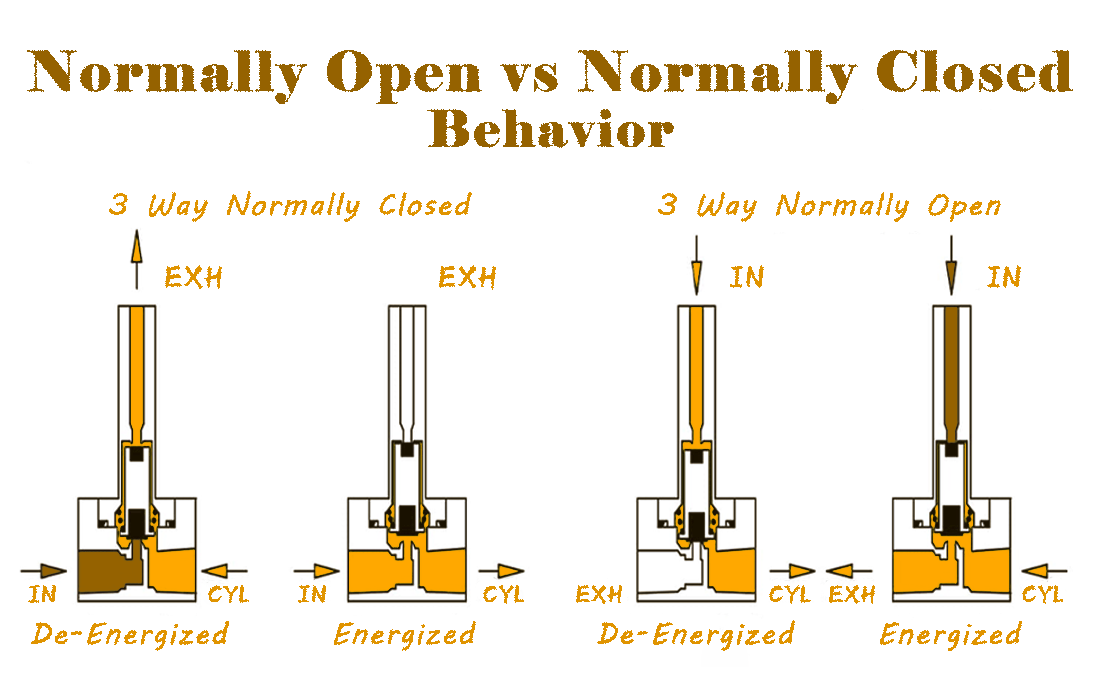

A 3 way normally closed solenoid valve blocks the supply port when de-energized while connecting the outlet to the exhaust port. As soon as the valve is energized, the internal spool shifts, allowing air supply to reach the actuator and sealing the exhaust.

This logic is widely used in industrial automation solenoid valves where fail-safe behavior is required. If power is lost, pressure is automatically released, allowing actuators to return to a safe position. Packaging machinery, pick-and-place units, and pneumatic clamps commonly rely on this principle.

Both 3 way direct acting solenoid valves and 3 way pilot operated solenoid valves can be designed with this normally closed behavior, making it a reliable option for systems that prioritize safety during unexpected shutdowns.

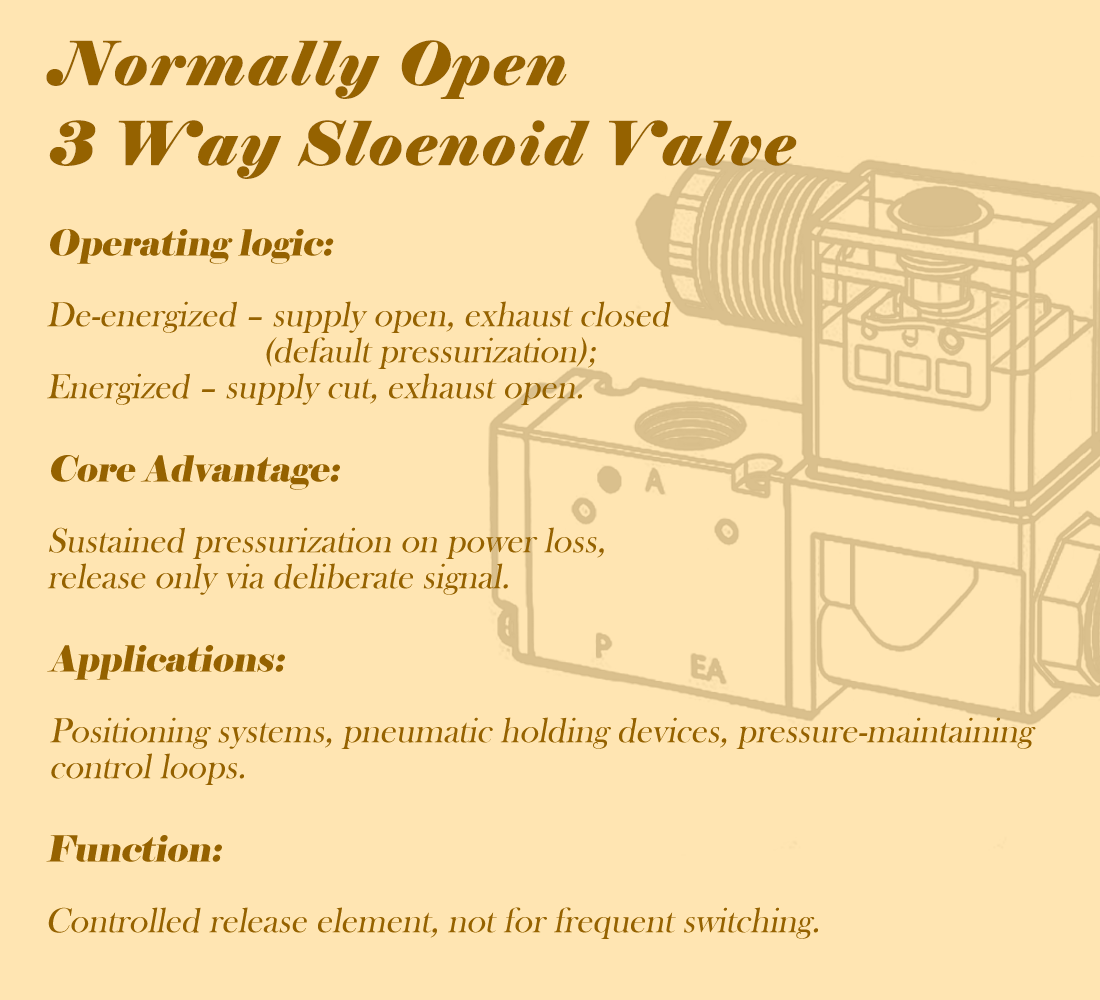

In contrast, a 3 way normally open solenoid valve maintains the connection between inlet and outlet in its de-energized state. The exhaust port remains closed until the valve is energized. Once power is applied, the supply is cut off and the outlet vents through the exhaust.

This configuration supports applications where maintaining pressure during power loss is essential. Examples include positioning systems, pneumatic holding devices, or control loops that must remain active until a deliberate signal commands exhaust.

In these cases, the valve functions as a controlled release element rather than a frequent switching component.

During 3 way solenoid valve switching, port transitions are not perfectly simultaneous. Brief transitional states may create pressure fluctuations, particularly in high speed 3 way solenoid valve applications or when multiple valves are mounted on modular manifold solenoid valves.

If not properly considered, these transient effects can lead to actuator vibration or delayed response. This is why selecting a pneumatic directional control valve involves more than choosing normally open or normally closed—it requires understanding how the valve behaves during real switching conditions.

For systems that require automatic exhaust on power loss, normally closed designs are typically preferred. Where pressure retention and controlled venting are critical, normally open configurations provide better results.

In practice, engineers also evaluate factors such as 3 way solenoid valve manifold mounting, coil voltage, response speed, and overall pneumatic layout to ensure stable and predictable operation across all conditions.

(FK9025)

System Problems Caused by Incorrect Port Identification of 3 Way Solenoid Valve

System Problems Caused by Incorrect Port Identification of 3 Way Solenoid Valve

Advantages of 3 Way Solenoid Valve in Single Acting Cylinder Control

Advantages of 3 Way Solenoid Valve in Single Acting Cylinder Control

Supply and Exhaust Logic of Normally Open and Normally Closed 3-Way Solenoid Valves

Supply and Exhaust Logic of Normally Open and Normally Closed 3-Way Solenoid Valves

Application Scenarios of Mixed Flow Path Design in 3-Way Solenoid Valves

Application Scenarios of Mixed Flow Path Design in 3-Way Solenoid Valves

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

How 3-Way Solenoid Valve Switching Sequence Affects System Stability

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap