Dec 12, 2025

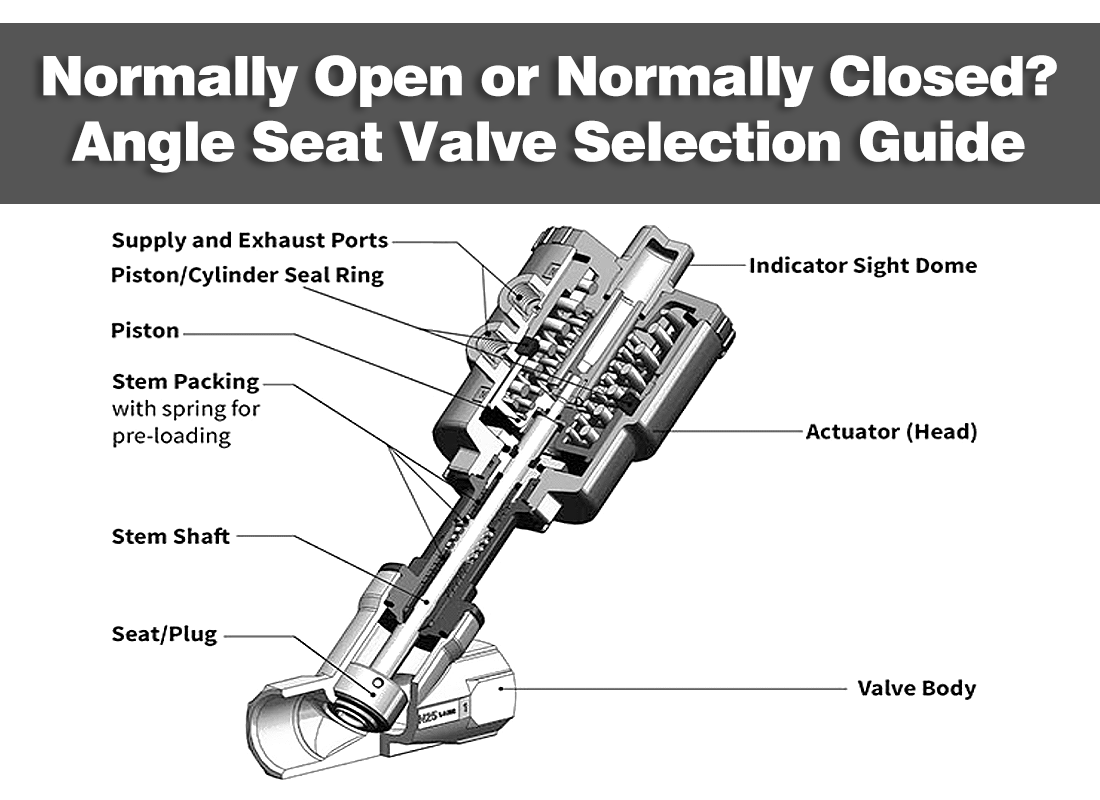

In many pneumatic and process-fluid systems, the angle seat valve is favored for its durability, high flow capacity, and ability to operate under demanding conditions such as steam, compressed air, and cooling water. Yet when choosing between normally open and normally closed versions, many engineers hesitate. The type you select influences energy consumption, system reliability, and especially the safety behavior of equipment during unexpected shutdowns.

Understanding how each design behaves—whether single-acting or double-acting—is the key to defining which configuration fits your application.

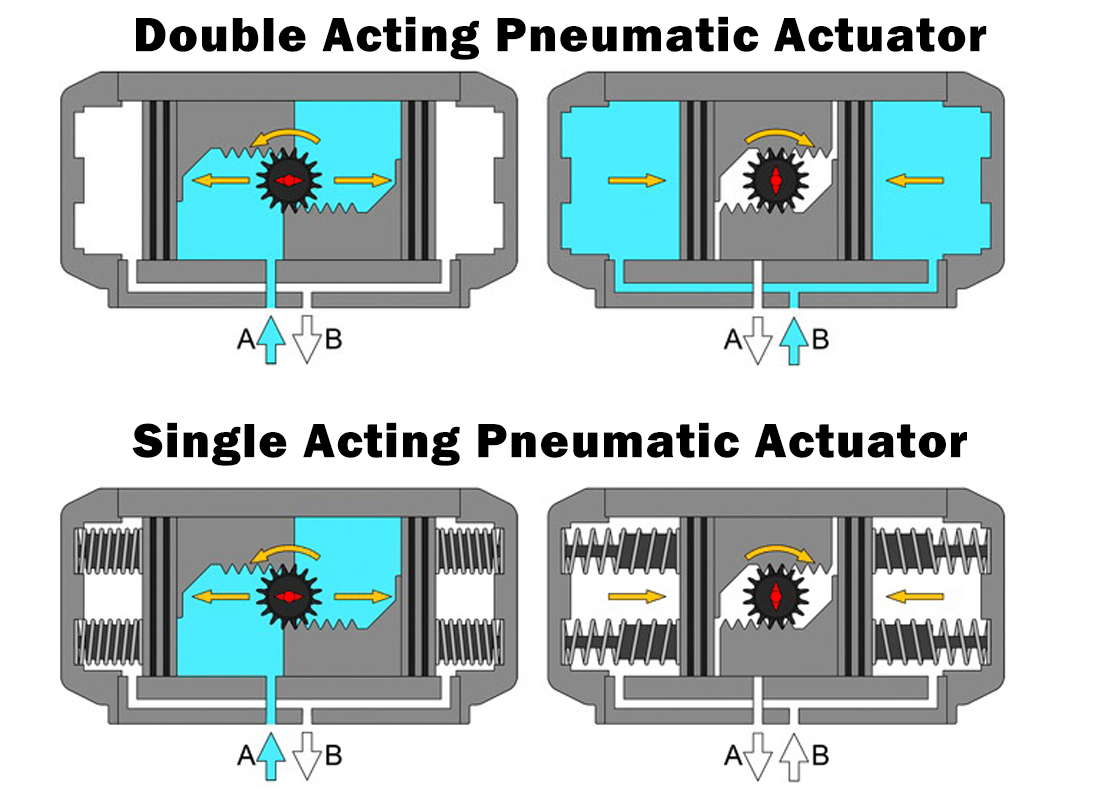

When selecting between different actuation modes, engineers often evaluate how the valve behaves during normal operation and under abnormal conditions. The following table summarizes the key differences between the two major actuation styles:

| Actuation Method | How It Works | Advantages | Limitations | Typical Applications |

|---|---|---|---|---|

| Single-Acting (Spring-Return) | Air pressure drives the valve in one direction; a built-in spring returns it to the fail-safe position. | Provides a defined fail-open or fail-closed state; safer for emergency scenarios; lower air consumption. | Spring force limits maximum cycle speed and torque; spring fatigue over long service life. | Safety-critical lines, steam systems, CIP/SIP units, shutoff functions. |

| Double-Acting | Air pressure is used for both opening and closing strokes. No spring is used. | Higher output force and torque; stable performance in high-pressure systems; ideal for high-cycle automation. | Loses fail-safe behavior unless combined with external safety devices; higher air consumption. | Automated process lines, mixing systems, high-frequency switching applications. |

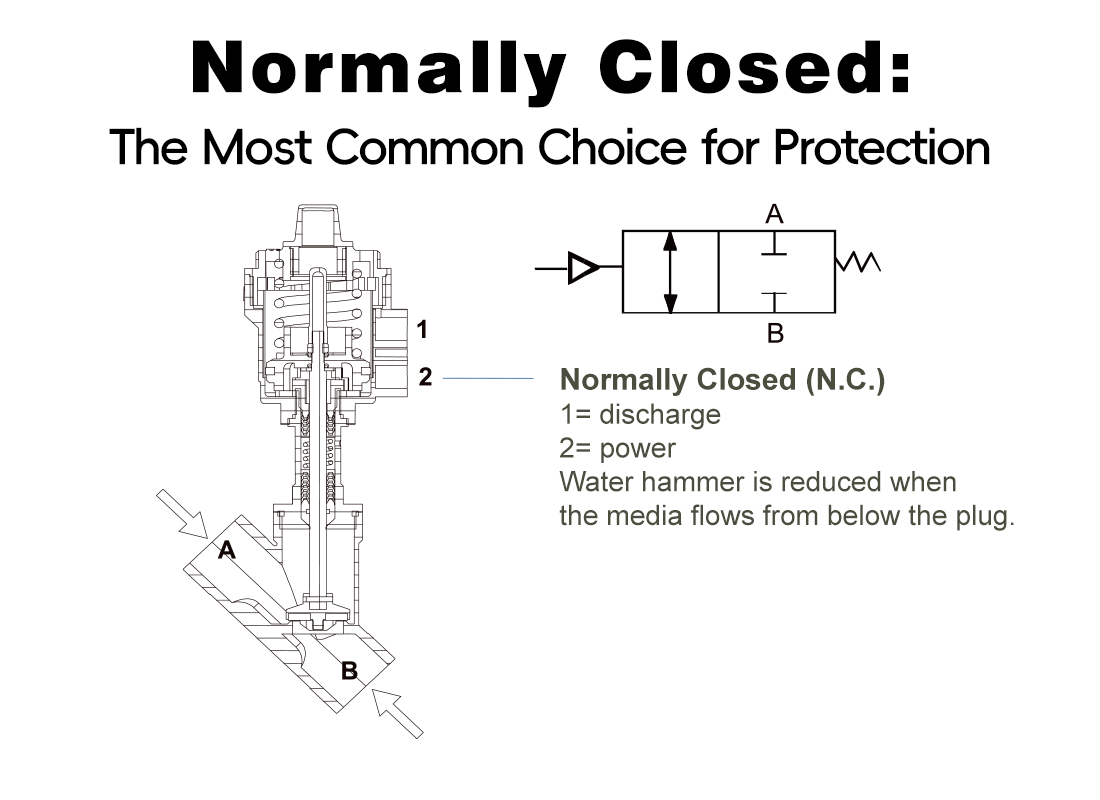

In a normally closed configuration, the valve stays shut until air pressure lifts the actuator stem. This setup is widely used because it naturally protects the system when something goes wrong.

It is the preferred option when:

◆ The process requires the valve to remain closed for most of the operating time

◆ Uncontrolled leakage would be dangerous or costly

◆ The medium involves steam, gases, or chemical fluids

◆ Shutdown procedures must be predictable and safe

In applications such as packaging, food equipment, sterilization lines, and steam distribution systems, a normally closed angle seat valve serves as a fundamental protection mechanism against accidental discharge.

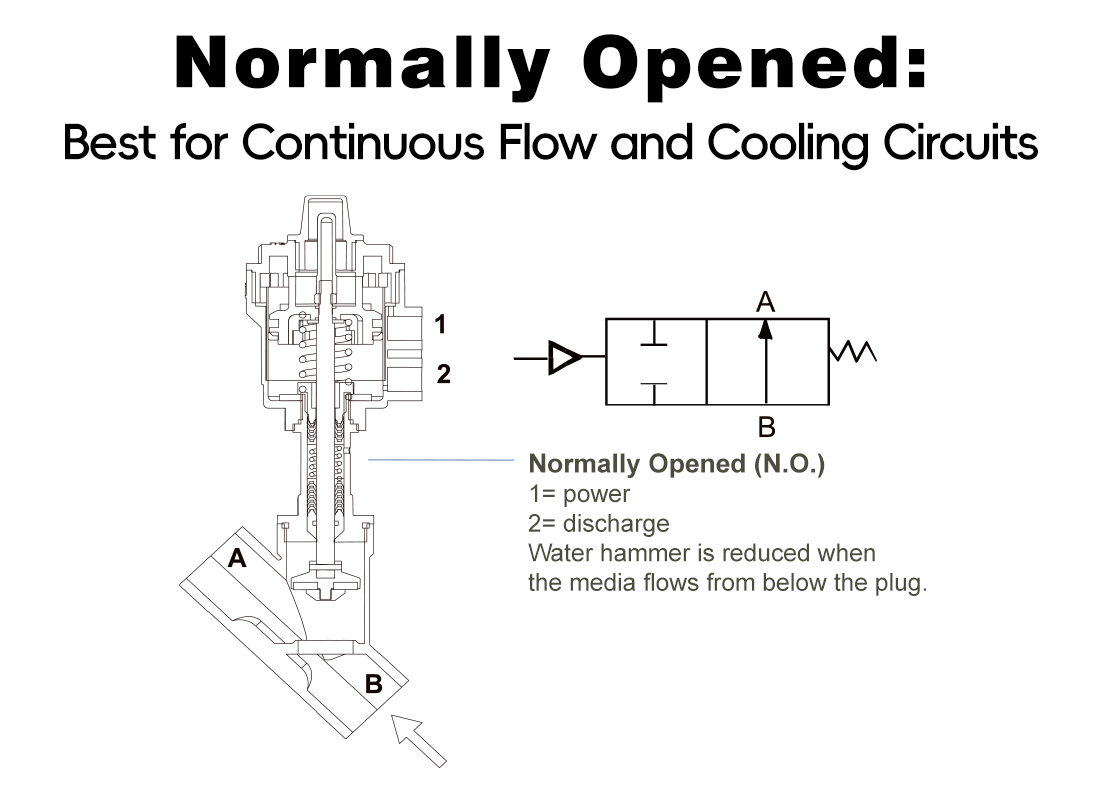

A normally open design suits systems where steady flow is more beneficial. The spring keeps the valve open, and an air signal forces it to close.

This arrangement is typically used when:

◆ The line must remain open for long periods

◆ Cooling or recirculation must continue even during air-supply interruptions

◆ The fluid contains particles that make frequent cycling undesirable

◆ Flow interruption may cause overheating or other risks

Cooling loops on machine tools, cleaning systems, and auxiliary process lines often rely on normally open valves to ensure safe and uninterrupted flow.

Most engineers can reach a clear conclusion by answering two practical questions:

•Mainly closed → normally closed is more efficient

•Mainly open → normally open reduces unnecessary cycling

A design that minimizes actuation extends the lifetime of both the actuator and the valve.

This is the defining factor for any single-acting angle seat valve.

•A closed position is safer → choose normally closed

(Typical for steam, gas, chemicals, or compressed-air mains)

•An open position is safer → choose normally open

(Typical for cooling water and recirculation systems)

Safety requirements, equipment behavior, and industry standards should guide this decision.

Although it offers no fail-safe position, a double-acting design remains valuable for demanding applications. It offers:

◆ Consistent movement under high pressure

◆ Better stability in precise flow-control sequences

◆ Reduced spring wear

◆ Longer life in high-cycle automation systems

These characteristics make it well-suited to systems where the fail position is handled by external safety devices.

If system safety depends on the valve’s default position, a single-acting design is usually the right approach. When operational continuity is the priority, a normally open version offers clear benefits. For high-pressure or high-cycle environments, a double-acting valve may be the most durable solution.

By understanding how each configuration behaves—mechanically and in real fail scenarios—you can choose the angle seat valve that best supports both safety and productivity. If you need angle seat vlaves, you can contact us directly.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

Nov 21, 2025 Blog

How to determine valve seat angleFOKCA ©1998-2025 All Rights Reserved Sitemap