Dec 11, 2025

In CNC machines, machining centers, and metal-cutting equipment, coolant plays a vital role in extending tool life and ensuring machining accuracy. It acts not only as a cooling medium but also as a lubricant and flushing fluid to remove metal chips. However, because coolant contains a large amount of metal debris and abrasive particles, the system demands valves with excellent wear resistance, corrosion resistance, and long-term stability. Based on these requirements, the VNC series coolant control valves—originally developed by SMC—have become a preferred choice for equipment manufacturers. Their structure, sealing method, and performance distinguish them from standard process valves.

Coolant carries large quantities of metal chips and abrasive particles, sometimes comparable to fine sand. If a standard valve—such as a soft-seal globe valve or engineering-rubber-sealed process valve—is used, the sealing surfaces can be quickly worn down by constant erosion. This often results in leakage, unstable switching, or spool sticking. Additionally, coolant contains highly alkaline chemicals that can corrode certain materials over time.

Therefore, the primary requirement for valves in coolant systems is resistance to abrasive flow, protection against seal damage, and reliable long-term operation. The VNC series addresses these challenges precisely.

Unlike most valves that rely on rubber sealing, the vnc series uses a metal-to-metal sealing structure. This brings two key advantages:

①Resistant to Chip Damage

Metal seals are unaffected by metal chip erosion. Issues common in rubber seals—tearing, indentation, chunking—simply do not occur. Even in harsh coolant environments, the durability remains significantly higher.

②Stable Sealing Across High-Cycle Operation

Metal seals maintain consistency during high-frequency opening and closing. Even with thousands of cycles per day, the valve continues operating without leakage or loss of precision.

For today’s high-speed production lines, fewer maintenance interruptions directly translate to higher productivity, and the VNC series aligns perfectly with this requirement.

Although vnc valves excel in coolant systems, they are not universal. Metal seals perform well in oil-based or additive-rich coolants, but pure water environments accelerate oxidation and rust, especially within the micro-gaps of the metal sealing surface. This may cause spool sticking or sealing failure.

Therefore, if the system uses pure water or high-water-content fluids, other process valves with appropriate sealing materials should be selected.

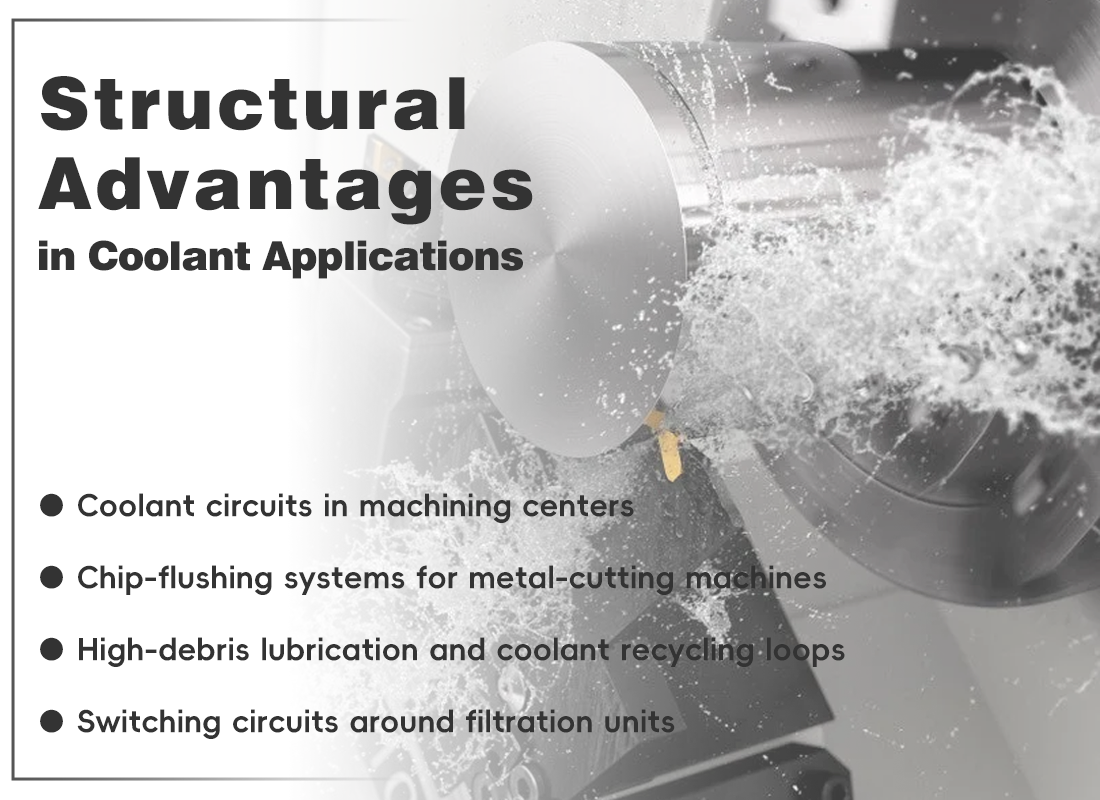

Beyond the sealing mechanism, the VNC series is structurally optimized for heavy-duty coolant systems. The valve features an enlarged flow path that reduces clogging risk; internal moving components use wear-resistant materials; and the outer body resists both chemical attack and mechanical impact.

These characteristics make VNC valves ideal for:

• Coolant circuits in machining centers

• Chip-flushing systems for metal-cutting machines

• High-debris lubrication and coolant recycling loops

• Switching circuits around filtration units

During high-speed machining, any coolant interruption may cause tool overheating or breakage. The VNC series is engineered to eliminate this risk at the valve level.

When choosing a VNC valve, the following parameters should be evaluated:

◆ Port size (bore): Match the required coolant flow rate and avoid unnecessary pressure loss.

◆ Body material: Choose based on the coolant’s chemical composition to ensure long-term

resistance.

◆ Pressure rating: Verify stability under pump startup surges and pressure fluctuations.

◆ Operation frequency: High-cycle systems should use the variants optimized for fatigue

resistance.

Thanks to a modular platform, the VNC series integrates seamlessly into various machine layouts and can replace many conventional globe valve designs while maintaining compatibility.

From the standpoint of equipment maintenance and productivity, the VNC series significantly reduces sealing wear, chip-induced damage, and spool sticking. For facilities that prioritize machining efficiency, a stable coolant system is essential—and the vnc series, with its durable metal sealing and robust internal design, has become a trusted industry solution.

Whether for new machine development or upgrading older systems, the VNC series provides a reliable foundation for coolant flow control.

If you need the VNC valves, you can contact us directly.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap