Dec 15, 2025

In pneumatic, hydraulic, and fluid control systems, pressure units appear everywhere—on valve datasheets, actuator nameplates, pressure gauges, and technical drawings. Yet in daily engineering work, one common challenge remains: different regions use different pressure units. Without a clear understanding of how they relate, selection mistakes and safety risks can easily occur.

A practical core conversion used across industrial applications is:

1 bar ≈ 1 kgf/cm² ≈ 0.1 MPa ≈ 101 kPa ≈ 14.5 psi ≈ 1 atm.

Mastering this relationship makes it much easier to read and compare specifications from different manufacturers.

The variety of pressure units is not a technical problem, but the result of historical and regional standards developing in parallel. Different industrial systems adopted units that suited their engineering habits, and many of them are still widely used today.

As a result, valves, pneumatic actuators, regulators, and filters often display two or even three pressure units on the same product—helping engineers avoid confusion when equipment is used internationally.

bar is one of the most widely used pressure units in industrial automation, especially in European-based systems. It is easy to read, intuitive, and convenient for on-site calculations.

A key advantage of bar is its simple relationship with MPa: 10 bar = 1 MPa

In pneumatic systems, typical operating pressures such as 6 bar or 8 bar are immediately recognizable, making bar especially practical for everyday engineering work.

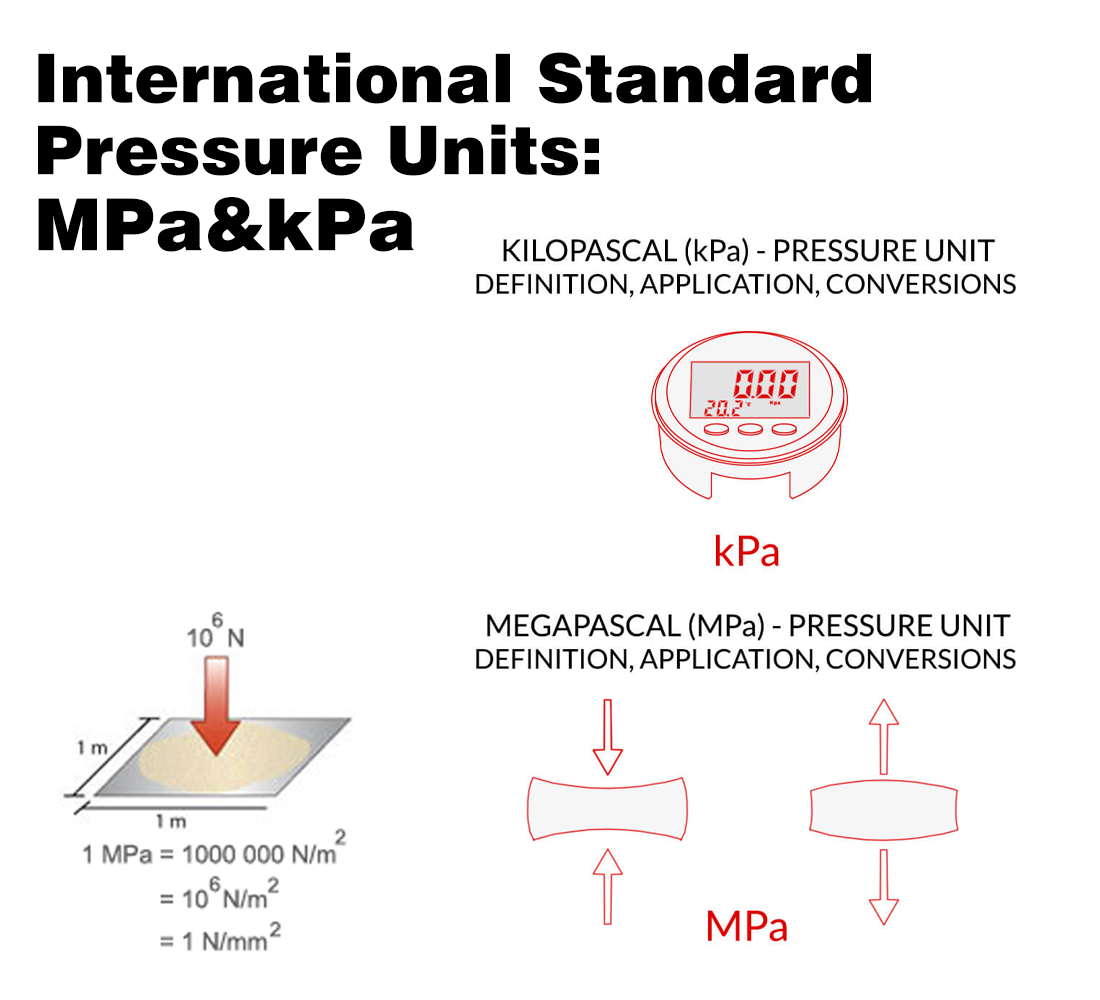

Pascal (Pa) is the official SI unit for pressure, with MPa and kPa used to express larger or smaller values.

In industrial specifications, MPa is commonly used for medium- and high-pressure ratings, such as valve pressure limits and actuator strength.

For example: 0.6 MPa ≈ 6 bar; 1.0 MPa ≈ 10 bar.

In China, Japan, and many technical documents, MPa is considered the most formal and standardized pressure unit.

kgf/cm², often shortened to kg or kgf in practice, is a pressure unit based on gravitational force. It is still frequently found on older equipment in China and Japan.

Its appeal lies in simplicity: 1 kgf/cm² ≈ 1 bar ≈ 0.1 MPa

Because of this near-equivalence, kgf and bar are often listed together on pneumatic valves and pressure regulators.

Anyone working with American equipment will encounter psi (pounds per square inch). It is the dominant pressure unit in North America and appears on many imported valves, actuators, and gauges.

A useful reference is: 1 bar ≈ 14.5 psi

For example: 90 psi ≈ 6.2 bar; 150 psi ≈ 10.3 bar.

Understanding this conversion is essential when servicing or integrating U.S.-made systems.

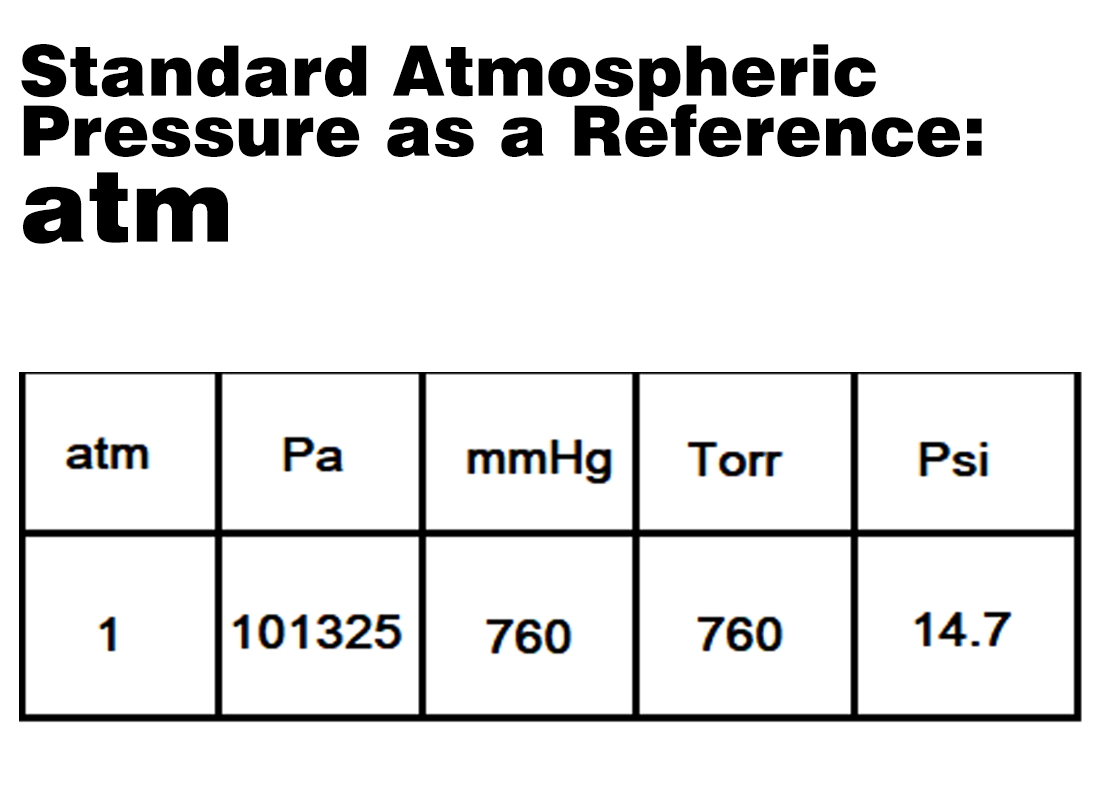

atm (standard atmosphere) is mainly used as a reference value rather than a design parameter.

One atmosphere represents average sea-level air pressure and is very close to bar: 1 atm ≈ 1.013 bar ≈ 101 kPa

In engineering practice, atm helps provide context for pressure values but is rarely used for component selection.

When selecting valves or pneumatic components, one rule is especially important:

always rely on the unit used for the product’s rated pressure, then convert if needed.

For example: If an actuator is rated at Max pressure: 0.8 MPa, The system pressure should not exceed 8 bar or 116 psi.

This approach is critical when integrating equipment from different regions or brands.

| Pressure Unit | Full Name | Typical Region of Use | Equivalent Value |

|---|---|---|---|

| bar | Bar | Europe, industrial standards | 1 bar |

| MPa | Megapascal | International (ISO, SI units) | 0.1 MPa |

| kPa | Kilopascal | International (SI units) | 100–101 kPa |

| kgf/cm² | Kilogram-force per square centimeter | China, Japan, legacy specs | ≈ 1 kgf/cm² |

| psi | Pounds per square inch | North America | ≈ 14.5 psi |

| atm | Standard atmosphere | Reference unit | ≈ 1 atm |

Pressure units themselves are not complicated—the real risk lies in assuming equivalence without conversion.

By remembering this core relationship:

1 bar ≈ 1 kgf ≈ 0.1 MPa ≈ 101 kPa ≈ 14.5 psi ≈ 1 atm,

engineers can confidently handle most industrial applications.

In valves, pneumatic actuators, and fluid control systems, understanding pressure units is fundamental to safety, reliability, and performance.

If you need any products, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap