Dec 11, 2025

In industrial fluid systems, the stability of equipment often depends on whether the selected valve can adapt to various working conditions. Fluid types may differ, pressure may fluctuate, and environments may change rapidly. This is why factories need a valve that performs reliably across multiple scenarios. The VNB process valves from SMC are built exactly for this purpose. Capable of handling air, water, light oil, and even vacuum, they serve as key components in manufacturing, processing, and automation equipment.

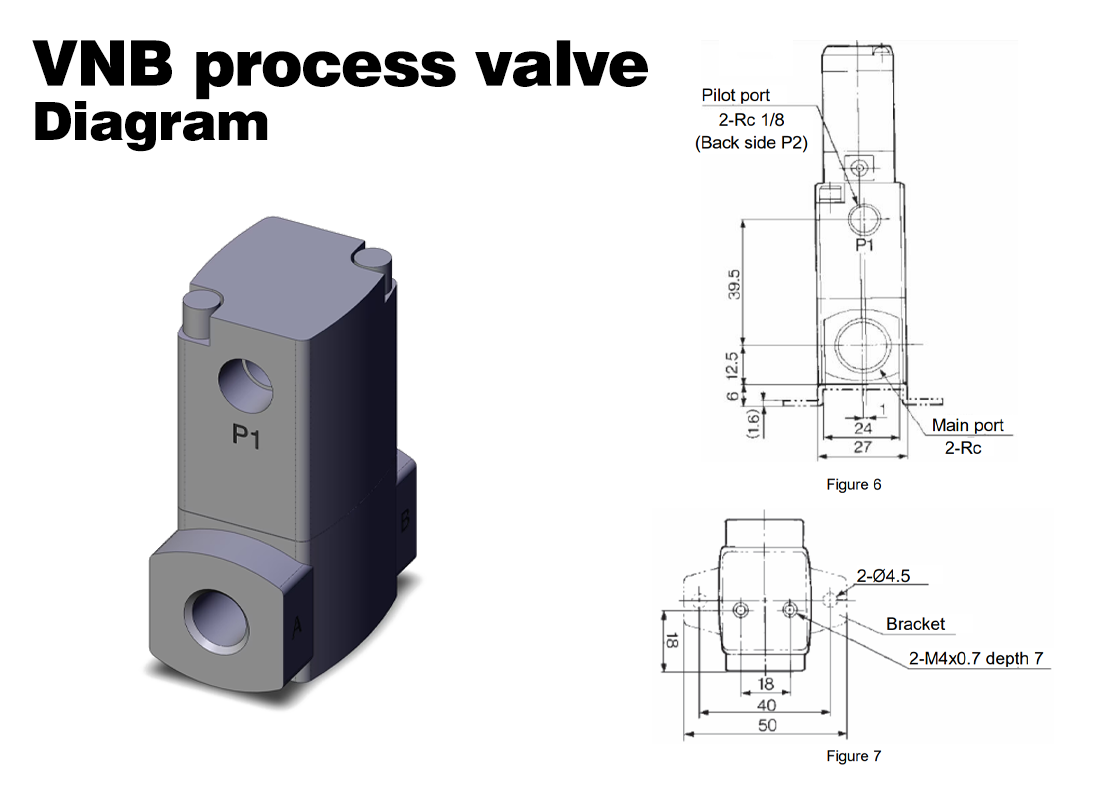

In production equipment, fluid conditions vary constantly, so a versatile valve must offer corrosion resistance, stable sealing, and dependable switching performance. The VNB process valves use brass, stainless steel, or corrosion-resistant alloys for the valve body, while the internal structure minimizes flow resistance, improving energy efficiency.

Available sealing options include NBR, FKM, and EPDM, allowing users to match materials with different fluid characteristics. EPDM is suitable for hot water and certain chemicals, while NBR performs well with oil-based fluids. This flexibility gives the VNB series wide application coverage without requiring multiple valve models.

On the production floor, one valve may need to be used for both pneumatic actuation and cooling water control, or for lubrication oil systems and vacuum circuits. The VNB process valves support multiple flow configurations and maintain stable switching even when handling high-viscosity oil or slightly contaminated water.

In vacuum applications, the valve design ensures extremely low leakage, making it a reliable choice for packaging systems, glass handling machinery, and electronic component transfer equipment.

From a maintenance standpoint, the VNB series offers a simple yet durable structure with longer service intervals than many general-purpose valves. The external threaded connection and standardized layout make disassembly efficient, allowing technicians to replace seals or clean internal passages quickly. For factories prioritizing continuous operation, this reduces downtime and helps maintain stable output.

VNB process valves do not rely on complex actuator structures, giving them exceptional installation flexibility. They perform reliably whether mounted vertically, horizontally, or upside down. In combination with SMC standard coils and waterproof connectors, the valves maintain consistent performance in environments exposed to moisture, oil mist, or dust.

From automated filling machines and cooling water loops to lubrication systems requiring frequent switching, engineers can integrate the VNB series into new or existing pipelines without major modifications.

The table below provides a practical overview of common VNB specifications to support quick evaluation:

| Parameter | Typical Range (VNB Series) | Application Value |

|---|---|---|

| Port size | R1/8 to R1 | Covers low- to high-flow pipeline systems |

| Max operating pressure | Approx. 1.0 MPa | Suitable for most air, water, and light-oil systems |

| Supported media | Air / Water / Light oil / Vacuum | Enables multi-purpose use |

| Seal materials | NBR / FKM / EPDM | Flexible selection for fluid and temperature conditions |

| Flow configuration | 2-port / 3-port | Greater design adaptability |

Many factories choose VNB process valves because they eliminate the need for multiple valve types across different fluid systems. Manufacturers of automation equipment, electrical systems integrators, and large production plants frequently use them in:

◆ Water or solution control in automated filling machines

◆ High-temperature water loops in plastic molding equipment

◆ Cooling oil circuits in metal processing lines

◆ Vacuum switching systems in packaging machinery

◆ Pure water and auxiliary gases in electronics manufacturing

In these scenarios, the VNB’s reliable operation and broad compatibility significantly reduce spare-parts complexity and make equipment maintenance more predictable and cost-efficient.

The VNB process valves strike a balance between cost, performance, durability, and versatility. They offer strong flow capacity, stable pressure tolerance, and reliable sealing options while supporting multiple fluid types.

For companies seeking a stable, efficient, easy-to-integrate fluid control solution, the VNB series offers outstanding value and long-term reliability.

If you need the VNB valves, you can contact us directly.

(FK9025)

Decoding Solenoid Valve Types: Key Differences of 4V, 3V, and 2V

Decoding Solenoid Valve Types: Key Differences of 4V, 3V, and 2V

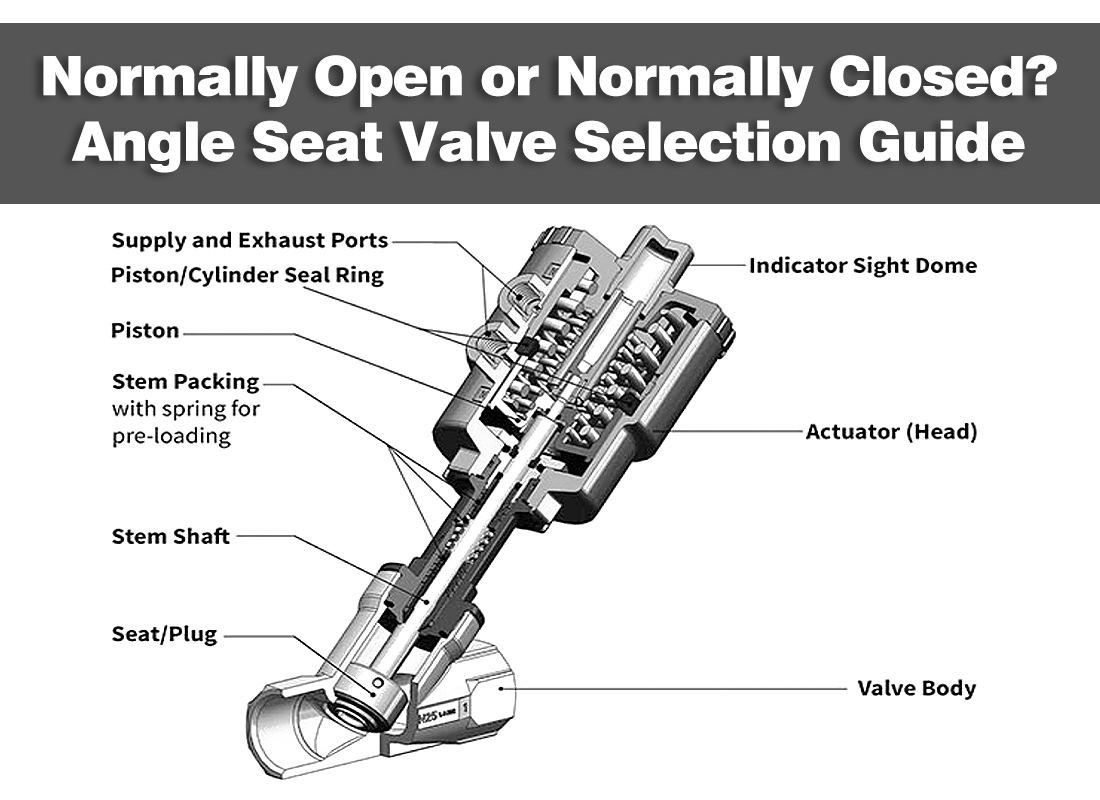

Normally Open or Normally Closed? Angle Seat Valve Selection Guide

Normally Open or Normally Closed? Angle Seat Valve Selection Guide

Why CNC Coolant Systems Prefer VNC Valves? A Reliable Solution for Leak Prevention

Why CNC Coolant Systems Prefer VNC Valves? A Reliable Solution for Leak Prevention

VNB Process Valves: An Efficient Solution for Multi-Purpose Fluid Control

VNB Process Valves: An Efficient Solution for Multi-Purpose Fluid Control

Valve Freezing Prevention Tips for Winter Maintenance

Valve Freezing Prevention Tips for Winter Maintenance

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap