Dec 12, 2025

When selecting solenoid valves, the model codes "4V", "3V" and "2V" often cause confusion. These codes are not product series—they describe the internal structure of the valve and how many flow paths it can control. Understanding these numbers helps you choose the right valve for flow direction, circuit design, and system reliability.

In pneumatic equipment, "V" stands for valve.

The number before it indicates:

Number of ports (flow paths)

Number of positions

Most commonly, the second number is "2" meaning two stable switching positions.

Thus:

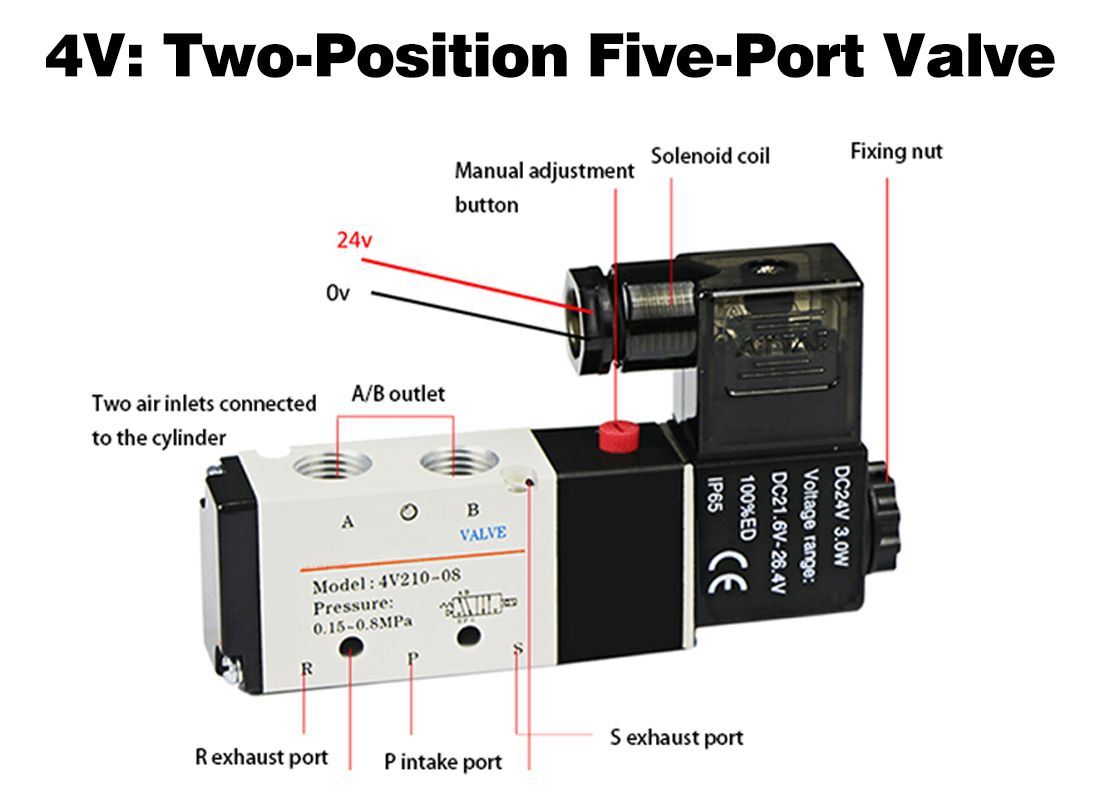

4V → 5/2 valve: two-position five-port valve

3V → 3/2 valve: two-position three-port valve

2V → 2/2 valve: two-position two-port valve

These structures determine whether the valve can reverse flow, exhaust air, or simply turn flow on and off.

A 5-port valve is the most common directional control valve in pneumatic systems.

It has five ports and two positions, designed to actuate double-acting cylinders.

◆ Typical port functions:

1 – supply

2 – output A

4 – output B

3 & 5 – exhaust

◆ Key strengths:

① Drives cylinders in both extend and retract directions

② Independent exhaust paths improve speed and responsiveness

③ Suitable for automated machines requiring directional switching

If the application involves back-and-forth motion, forward/reverse switching, or dual-direction control, the 4V (5/2) structure is the standard choice.

A 3-port valve includes inlet, outlet, and exhaust. Its structure is simpler and ideal for:

◆ Single-acting cylinders

◆ Angle seat valves and diaphragm valves

◆ Air blow-off or vacuum release

◆ Basic on/off pneumatic functions

Unlike a five-port valve, it cannot reverse direction, but it offers:

◆ Compact size

◆ Fewer leakage points

◆ Lower cost

If the actuator returns by spring or only needs a one-direction stroke, a 3V (3/2) valve is usually the best match.

A 2-port valve has only an inlet and outlet.

It is essentially a flow shut-off valve and is widely used in:

◆ Air, water, oil, and general fluid switching

◆ Main line open/close control

◆ Filling, dosing, and dispensing

◆ Simple system start/stop operations

It does not control flow direction and has no exhaust path, but it is the most reliable, cost-efficient and universal, Ideal when the requirement is strictly open or closed.

| Model | Ports | Positions | Typical Use | Function Characteristics |

|---|---|---|---|---|

| 4V (5/2 valve) | 5 | 2 | Double-acting cylinders | Full forward/reverse control, fast switching |

| 3V (3/2 valve) | 3 | 2 | Single-acting actuators, angle seat valves | Simple switching with automatic return |

| 2V (2/2 valve) | 2 | 2 | Fluid ON/OFF control | Basic shut-off, widest fluid compatibility |

You can determine the right structure with a simple decision process:

Yes → choose 4V (5/2 valve)

No → continue

Yes → choose 3V (3/2 valve)

Only flow ON/OFF required → choose 2V (2/2 valve)

5-port valves generally provide higher airflow; 2V valves depend on their orifice size.

When the system requires fast response, reversing motion, or heavy cycling, 4V and 3V valves are usually more suitable than 2V valves.

Although 4V, 3V, and 2V look like simple codes, they describe how the valve controls fluid paths.

A helpful rule of thumb: 5-port valves control direction, 3-port valves control switching, and 2-port valves control ON/OFF flow.

With this understanding, selecting the right solenoid valve for your pneumatic system becomes much easier and more precise.

If you need solenoid valves, you can contact us directly.

(FK9025)

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Fluid Retention During Supply and Exhaust Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Pressure Fluctuation During Flow Path Switching in 3-Way Solenoid Valves

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Control Characteristics of 2-Way Solenoid Valves in Intermittent Liquid Supply Systems

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

Impact of Contaminated Media on 2-Way Solenoid Valve Cores

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

2 Way Solenoid Valve Performance Differences in Gas and Liquid Media

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap