Dec 16, 2025

In the previous article "Valve Flow Coefficients CV & KV," we discussed in detail the differences, applications, and conversion formulas for valve Cv and Kv values. Essentially, both Kv and Cv accurately describe a valve's flow capacity under different standards. Higher values indicate greater flow capacity and lower resistance to fluid flow, which is one of the key criteria for evaluating valve performance.

However, whether it’s Cv under imperial standards or Kv under metric standards, both are measured using water as the medium at specified temperatures. For engineers handling oils, solutions, steam, or other viscous fluids, directly applying Kv values for valve selection will almost always lead to undersizing. This can result in failure to meet design flow rates, reduced production output, and even loss of control.

Therefore, we need to calculate correction factors for Kv based on different fluids to ensure accurate valve selection.

Before diving into calculations, it’s important to note that a safety margin is typically reserved during selection. For low-viscosity fluids (usually below 20–30 cSt), the effect of viscosity can be neglected, and the Kv value for water can be used directly.

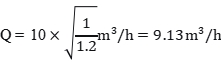

Assume a Fokca valve has a Kv of 10.

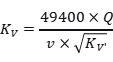

From the formula:

When the medium is water (G=1) and ΔP=1 bar, the flow rate m3/h.

If the fluid is changed to concentrated brine with a density 1.2 times that of water (ρ=1200 kg/m3), the relative density G=1.2. Then:

It can be concluded that higher fluid density reduces valve flow. Since the actual Kv′ is proportional to the flow rate, Kv′ also decreases.

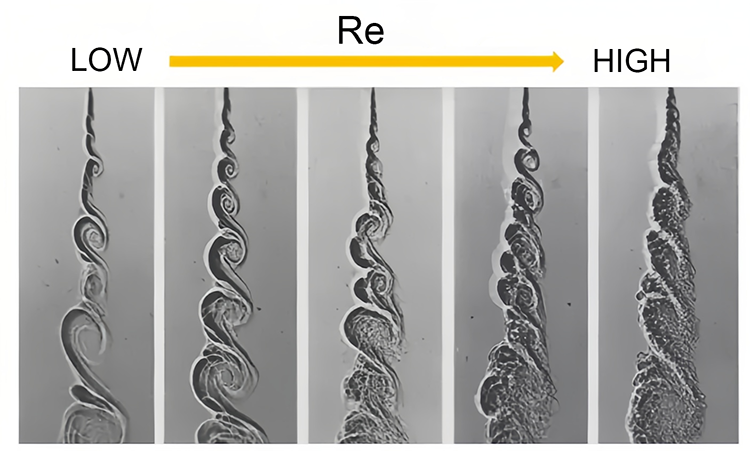

The behavior of viscous fluids through valves is more complex. The Kv value is derived from low viscosity Newtonian fluids like water, where inertial forces dominate over viscosity, leading to turbulent flow. In viscous fluids, however, fluid particles move in orderly, parallel layers with minimal mixing. Viscosity dominates in laminar flow, where internal friction is significant, making laminar flow more likely. In such cases, the Reynolds number—characterizing the flow regime—must be calculated.

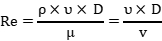

In piping systems, the Reynolds number is defined as:

where:

ρ: fluid density (kg/m³)

v: characteristic fluid velocity (m/s)

D: characteristic pipe diameter (m)

μ: dynamic viscosity (Pa·s)

ν: kinematic viscosity (m²/s), ν=μ/ρ

This formula represents the ratio of inertial forces to viscous forces.

For valve systems, after transformation, empirical data, engineering derivation, and unit conversion, the Reynolds number formula becomes:

This is a semi-theoretical, semi-empirical specialized formula. Its purpose is to bypass the complex internal geometry of the valve and directly use a dimensionless number (Rev) to assess the impact of viscosity on the valve flow coefficient, enabling accurate correction. In practical engineering, this formula is used directly as it has become a standard industry algorithm.

In classic pipe flow, Re<2000 indicates laminar flow, and Re>4000 indicates turbulent flow. If the calculated Reynolds number is ≤ 4000, viscosity correction is required.

Based on the calculated RevRev value, refer to the FR vs. Rev curve provided by the valve manufacturer. Different valve types (e.g., ball valves, butterfly valves, globe valves) have different curves. The general trend is: lower Rev (greater viscosity effect) leads to a lower FR.

Viscous fluids often also have densities different from water, so the density corrected Kv′ must first be calculated as described earlier.

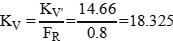

Finally, calculate the corrected actual required Kv value:

Since FR≤1, the corrected Kv value increases, meaning a larger valve bore is needed to achieve the same flow rate.

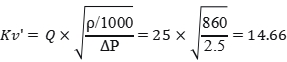

Assume a globe valve is required for a lubricating oil transfer line with the following process data:

Medium: ISO VG 68 industrial lubricating oil

Operating temperature: 40 °C

Maximum volume flow rate Q: 25 m³/h

Valve pressure drop ΔP: 8.0 (inlet) − 5.5 (outlet) = 2.5 bar

Medium density ρ: 860 kg/m³ (at 40 °C)

Medium kinematic viscosity ν: 68 cSt

Pipe size: DN100

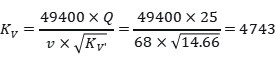

The calculated Rev≈4743 is just entering the turbulent region but far below the turbulence intensity for water (typically Rev105). This means viscosity has a significant effect and must be corrected.

Referring to the curve (common trend):

For Rev in the range 3000–7000, FR is approximately 0.80–0.90.

For conservative selection (ensuring flow rate is met), we take the lower value: FR=0.8.

18.325/25=0.73325

Valves are typically operated between 30% and 80% opening, which meets the requirement.

For any fluid with a kinematic viscosity > 20 cSt, the viscosity correction calculation above must be performed. The most reliable approach is to use the valve manufacturer’s official sizing software, input all parameters, and let the software perform precise calculations and product recommendations automatically.

(FK9009)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap