Dec 17, 2025

In industrial automation systems, many applications require more than a simple “open or close.” Media often needs to be diverted between different pipelines, switched from one outlet to another, or combined from multiple inlets. This is exactly where a pneumatic three-way seat valve shows its strength. Represented by the TV series, this type of valve differs fundamentally from a conventional globe valve and provides far greater flexibility in fluid control.

A pneumatic three-way seat valve is essentially a three-port valve driven by a pneumatic actuator. Unlike a standard globe valve with only one inlet and one outlet, a three-way seat valve has three ports, allowing different flow path configurations depending on the internal valve design.

The TV series follows this principle by using compressed air as the control force. The actuator moves the valve plug between defined positions, enabling the fluid to switch from one flow path to another.

In simple terms, a globe valve answers the question “on or off,” while a pneumatic three-way seat valve answers “where should the flow go.”

The structure of a conventional globe valve limits it to controlling a single flow path. It is ideal for isolation and basic shut-off tasks, but it cannot manage flow diversion.

The defining advantage of the TV series pneumatic three-way seat valve lies in its configurable flow functions.

Depending on the application, the valve can:

•Switch one medium between two pipelines

•Selectively combine two media into a single outlet

•Alternate between production flow and cleaning flow

This capability makes the three-way seat valve far more suitable for systems that require frequent process switching.

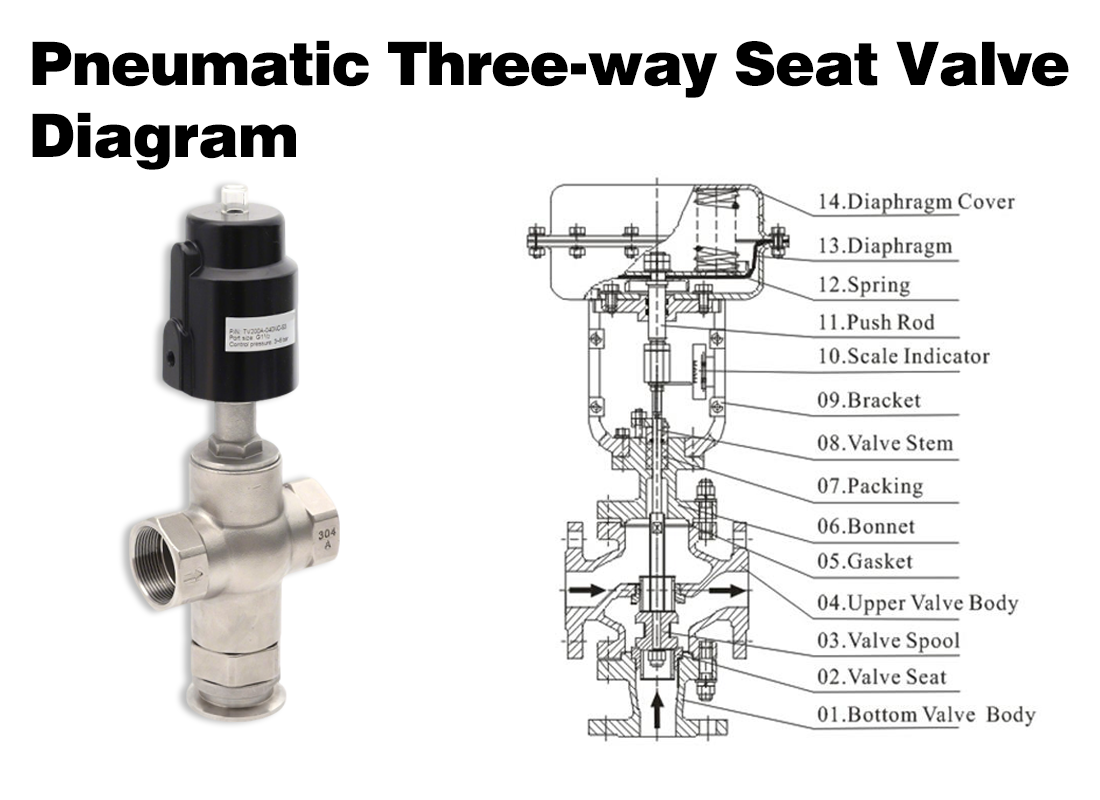

The TV series adopts a classic seat valve structure. The valve plug moves linearly against the valve seat and is actuated pneumatically, resulting in several practical advantages:

① Fast response: Pneumatic actuation ensures stable and rapid switching

② Reliable sealing performance: Seat valve design performs well under medium and low pressures

③ Multiple flow configurations: Flow paths can be selected to match process requirements

④ Easy maintenance: A clear structure supports long-term automated operation

For equipment manufacturers, this design helps simplify system layouts while maintaining reliable control.

During valve selection, engineers often compare a pneumatic three-way seat valve with a pneumatic three-way ball valve. Although both provide three ports, their strengths differ.

To better understand how a pneumatic three-way seat valve differs from other solutions, the table below compares it with a pneumatic three-way ball valve.

| Comparison Item | Pneumatic Three-Way Seat Valve (TV Series) | Pneumatic Three-Way Ball Valve |

|---|---|---|

| Flow path control | Multiple selectable flow paths, supports diversion and mixing | Fixed L-port or T-port configuration |

| Switching accuracy | High precision, suitable for frequent flow switching | Moderate, mainly for simple routing |

| Sealing principle | Seat sealing, optimized for process control | Ball sealing, focuses on shut-off |

| Response behavior | Smooth and stable during switching | Fast switching, less control resolution |

| Medium suitability | Liquids, gases, steam, process fluids | Clean fluids with low contamination |

| Typical applications | Process automation, dosing, flow distribution | On/off control and simple flow direction change |

| Control flexibility | High – flow function can be customized by valve design | Limited to predefined ball port structure |

This structural flexibility is why the TV series is often selected for systems that require more than simple on/off control.

Thanks to its flexible flow path control, the pneumatic three-way seat valve is widely used in:

◆ Process switching within automated production lines

◆ Rapid changeover between cleaning and operating modes

◆ Selective transport systems handling multiple media

◆ Equipment designs that aim to reduce valve count and simplify piping

In many cases, a single three-way seat valve can replace two conventional globe valves, saving installation space and reducing system complexity.

As industrial automation continues to advance, simple on/off control is no longer sufficient. The TV series pneumatic three-way seat valve upgrades the valve’s role from a basic shut-off component to a process flow control element.

For systems that demand flexible switching and stable operation, it represents a practical and efficient solution.

If you need TV series pneumatic three-way seat valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap