Dec 16, 2025

In industrial automation, engineers often face this question during selection: Can pneumatic valves be used in vacuum conditions? Many product datasheets list the working pressure range as “0–X MPa,” which may give the impression that pneumatic valves are only suitable for positive-pressure systems. In fact, as long as the valve’s structure and sealing type are appropriate, pneumatic valves can operate reliably in vacuum environments and have long been a mature solution on automated production lines.

To answer this question, it’s important to clarify the logic behind pressure ratings. Industrial valves typically indicate gauge pressure, not absolute pressure. Standard atmospheric pressure corresponds to an absolute pressure of approximately 0.1 MPa (~1 bar). When a gauge reads 0, the system is actually at atmospheric pressure.

Vacuum, by definition, is a condition below atmospheric pressure. Therefore, when a pneumatic valve is rated “working pressure 0–0.8 MPa,” the “0” does not mean it cannot operate below atmospheric pressure—it simply indicates the valve is not designed to withstand a positive pressure differential.

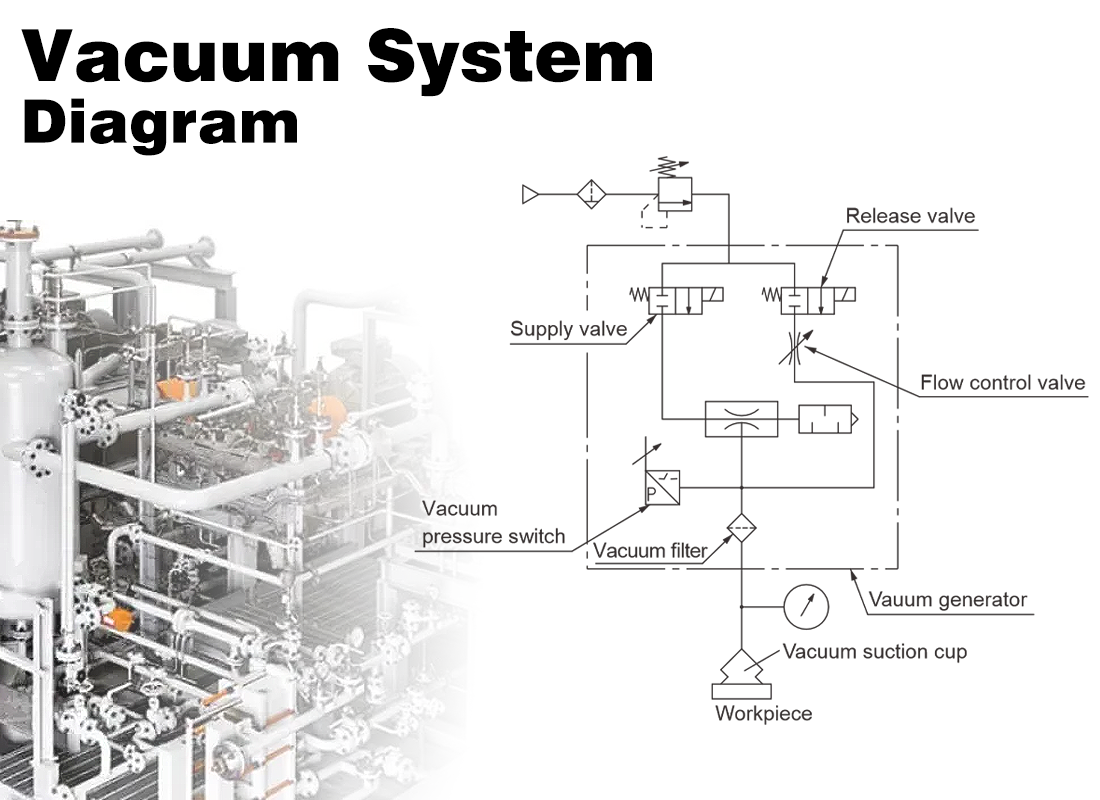

In a vacuum system, the core function of the pneumatic valve remains unchanged: it uses a pneumatic control signal to actuate the valve spool or poppet, enabling flow control or switching. The difference is that the medium flowing through the valve is no longer pressurized gas or liquid but air or process gas being continuously evacuated.

For practical reference:

Standard atmospheric pressure: ~0.1 MPa (1 bar absolute)

Common industrial vacuum levels:

10⁻¹ MPa range (~ -0.9 bar gauge)

10⁻² MPa range (higher vacuum)

Within this range, as long as the valve has reliable sealing and reasonable structural design, pneumatic valves can operate stably without affecting the system vacuum.

In vacuum applications, a smaller pressure value corresponds to a higher vacuum level:

-0.6 bar → Medium vacuum

-0.9 bar → High vacuum

Approaching -1 bar → Near ultimate vacuum (relative to atmospheric pressure)

This is why vacuum system specifications often use 10⁻¹, 10⁻², etc. For most industrial automation applications, pneumatic valves perform well in the 10⁻¹ to 10⁻² vacuum range.

While the answer is “yes, they can be used,” not all pneumatic valves are automatically suitable for vacuum systems. Selection should focus on:

Even minor leaks are amplified in vacuum conditions. The valve spool seal, seat fit, and O-ring material are critical.

Compared to positive pressure, vacuum more easily “sucks in” external air. Simpler structures with fewer sealing surfaces improve vacuum retention.

Pneumatic valves are driven by the control air source, not the medium itself, ensuring reliable operation under vacuum.

Ultra-high vacuum (e.g., semiconductor-grade) requires specialized vacuum valves. Standard pneumatic valves are sufficient for industrial vacuum levels of 10⁻¹ to 10⁻² MPa.

On many automated production lines, pneumatic valves are widely used for vacuum suction, workpiece handling, and vacuum clamping, for simple reasons:

Stable actuation force: Independent of medium pressure fluctuations

Fast response: Suitable for high-frequency switching

Mature structure: Low maintenance costs and high versatility

As long as the control air source is stable, valve operation is not affected by vacuum fluctuations.

In a word, pneumatic valves are not only usable in vacuum—they are a mature and reliable solution in medium to high vacuum ranges. Understanding pressure rating methods and distinguishing gauge vs. absolute pressure is key to proper selection.

With vacuum levels controlled within 10⁻¹ to 10⁻² MPa and careful choice of sealing structure and valve design, pneumatic valves can operate long-term and reliably in vacuum systems, providing dependable control for automated equipment.

If you need any pneumatic valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap