May 07, 2025

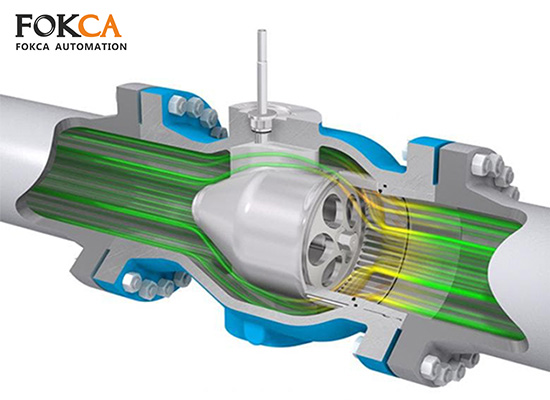

Pneumatic axial valve is a valve that controls fluid flow along an axis direction through a pneumatic actuator. Compared with other traditional valves, pneumatic axial flow valves typically use pneumatic control systems and do not require manual operation. The structure composed of pneumatic actuators provides power to drive the opening and closing of the valve, thereby adjusting flow rate, pressure, or fluid direction. It can achieve automated control, reduce manual intervention, and is commonly used in automation systems to ensure efficient and precise control of fluid systems.

Axial flow valve excels in high-precision regulation of fluid flow and pressure, while maintaining stable automation system safety. Before introducing the working principle of Axial valve, let's first introduce the components that make up Axial valve:

The pneumatic axial flow control valve is mainly composed of a valve seat, a valve disc, a valve body, an actuator, and a seal, each of which plays a different role:

Valve body: As the structural framework of the entire valve, the valve body is usually made of corrosion-resistant and high-strength materials, such as stainless steel or cast iron, to ensure long-term use of the valve in high-pressure and high-temperature environments.

Flap valve: A flap valve is a movable part inside a valve that is connected to a pneumatic actuator and moves forward or backward under its push. Control the opening of the fluid flow channel. When the pneumatic axial valve is fully open, the valve disc is usually pushed towards the other end of the pipeline by the pneumatic actuator, keeping the valve fully open; When the pneumatic axial valve is fully closed, the valve disc is pushed back to the valve seat, in close contact with the valve seat, thereby preventing fluid flow from moving in the direction of the fluid.

Pneumatic actuator: The movement of the valve disc is driven by compressed air. It can adjust the valve opening based on external control signals to achieve flow or pressure regulation.

Seals: Seals are used to ensure that fluid does not leak from the joints of valves, and are usually made of high wear-resistant and high-temperature resistant materials such as rubber, polytetrafluoroethylene, etc.

Control system: The control system of pneumatic axial flow control valve usually includes sensors, actuator controllers, and PLCs, all of which are used to accurately adjust the opening and operation of valves to ensure control accuracy.

Valve seat: The valve seat is a fixed part in contact with the fluid inside the valve body, providing a sealing surface,Effectively isolate the fluid between the valve disc and the valve body to prevent leakage. Due to the need to come into contact with fluids, the valve seat is made of corrosion-resistant and high-temperature resistant materials such as stainless steel and polytetrafluoroethylene. During the process of fluid flow, the valve seat should be designed to minimize fluid flow resistance and avoid excessive pressure drop or energy loss.

The working principle of Axial Flow Control Valve is relatively simple, mainly relying on pneumatic actuators to push the flap valve to move in the direction of fluid flow, thereby achieving flow regulation. The following are the specific working steps of a pneumatic axial flow valve:

Air supply: The air source supplies air to the pneumatic actuator through pipelines. Prior to this, the gas source would control the flow rate through regulating valves to ensure precise and stable pressure operation of the actuator.

Pneumatic control signal: The actuator receives a signal from the PLC or DCS control system to control the input pressure or flow rate of the gas, determining whether the flap valve moves forward or backward.

Open the valve: When the pneumatic actuator pushes the flap valve to move axially in the opposite direction of the valve seat, the valve flap moves away from the valve seat, and the flow channel gradually opens, allowing fluid to flow through the valve. The opening of the flap valve determines the flow rate of fluid through the valve, which is proportional to the control pressure of the pneumatic actuator.

Closing the valve: When the pneumatic actuator stops applying pressure or applies reverse pressure, the valve flap is pushed towards the valve seats and the flow channel gradually closes.

The uniqueness of pneumatic axial valves lies in their ability to regulate fluid flow through precise movement of valve flaps. As the flap valve opens, the fluid flow rate gradually increases; When the flap valve is closed, the flow decreases and eventually stops completely

The sealing performance of valve flap and valve seal is one of the important characteristics of axial vale. The design and material of the valve seal determine the sealing effect when closed. Usually, the sealing surface of a pneumatic axial flow control valve is achieved by the contact between the flap valve and the vale sealing.

Axial Vale is typically connected to automation control systems for remote monitoring and control in industrial applications. The action of the pneumatic actuator matches the instructions of the control system, ensuring that the valve adjusts the flow or pressure according to real-time demand.

Efficient fluid control: The most important advantage of axial valve is its precise regulation of fluid flow and pressure, ensuring stable operation of the system under different working conditions. This is crucial for various industrial applications.

Automation and Intelligence: Axial valve's pneumatic actuators can be connected to automation systems such as PLC or DCS, making valve operations more intelligent and automated. This can reduce manual errors and improve efficiency.

Energy saving and reduced failure rate: The design of pneumatic axial flow valves applies fluid dynamics principles, which can effectively reduce flow resistance, energy consumption, mechanical losses, and improve system stability and lifespan.

Safety and reliability: Pneumatic axial flow valves have a high degree of safety. In the event of a malfunction or abnormal situation, they can be quickly closed or adjusted to prevent further serious accidents or damage, ensuring the long-term stable operation of the system.

Oil and gas industry: Pneumatic axial flow valves can be used to control the flow direction and velocity of fluids in pipelines, ensuring the safe transportation and processing of oil and gas.

Chemical industry: In the process of chemical reactions, pneumatic axial flow valves can accurately control the flow rate and quantity of reactants, ensuring the stability and safety of the reaction.

HVAC system: Pneumatic axial flow valves are used to control the temperature, humidity, and air flow inside buildings, ensuring environmental comfort and energy efficiency.

Food and pharmaceutical industries: In these industries, pneumatic axial flow valves are used to precisely control fluid functions, ensuring product quality and hygiene requirements.

Choosing the appropriate pneumatic axial flow valve is crucial for ensuring the stable and efficient operation of the fluid system. Appropriate valves can improve system efficiency, extend equipment lifespan, and reduce failure rates. During the selection process, multiple factors need to be considered, including valve size, material, pressure rating, control method, installation environment, and maintenance requirements

1. Choose the appropriate valve size based on system requirements

The size of the valve directly affects the control ability of fluid flow and the performance of the system. Choosing the correct valve size can ensure efficient operation of the system

2. Choose valve material

The selection of valve materials should consider the characteristics of the fluid, the temperature and pressure of the working environment, and possible corrosiveness.

3. Select pressure level

The pressure rating of the valve needs to match the working pressure of the system.

4. Understand the control method of pneumatic valves

5. Consider installation environment and maintenance requirements

Fokcavalve's pneumatic axial flow valve not only supplies performance, but also service and technical support. Here are our brand advantages, showcasing how we can provide better value and products to our customers. As an axial flow control valve manufacturer, we offer the following services:

Customized services to meet multiple needs: Understanding that each customer's needs are unique, therefore providing flexible customized services.

High quality materials: Our pneumatic axial flow valve is made of high-quality materials that meet international standards, ensuring the stability and durability of the valve during long-term operation. For example, stainless steel SS3316 can ensure the long-term stable operation of valves in chemical corrosion environments.

Professional technical support: We help you solve various problems encountered during the selection, installation, and maintenance process.

Industry confidence: We have many successful customer cases covering different fields and industries.

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Jul 30, 2025 Blog

AWG:Why do We Need the American Wire Gauge?

Jul 28, 2025 Blog

How to check air solenoid valve?

Jul 24, 2025 Blog

How to check the solenoid valve?

Apr 22, 2025 Blog

Pneumatic Globe Control Valve

Apr 16, 2025 Blog

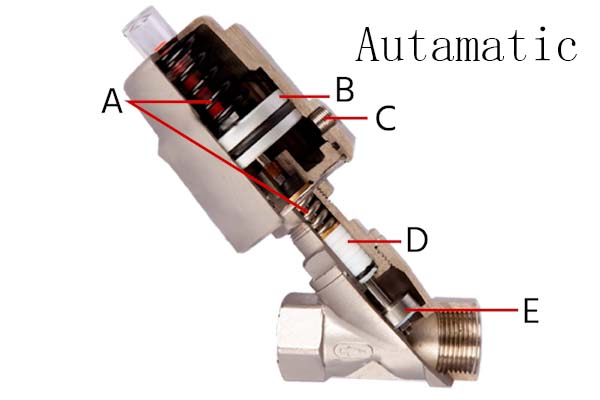

A Guide to Understand Angle Seat Valve

Apr 10, 2025 Blog

Limit Switches in Valve Control SystemsFOKCA ©1998-2025 All Rights Reserved Sitemap