Dec 23, 2025

In automated valve systems, the valve actuator plays a critical role by converting control signals into mechanical movement that opens or closes the valve. While much attention is often given to the valve body itself, actuator size is equally important. The size of an actuator directly affects valve sealing performance, response speed, and suitability for different pressure conditions. Choosing the right actuator size is therefore essential for reliable and efficient operation.

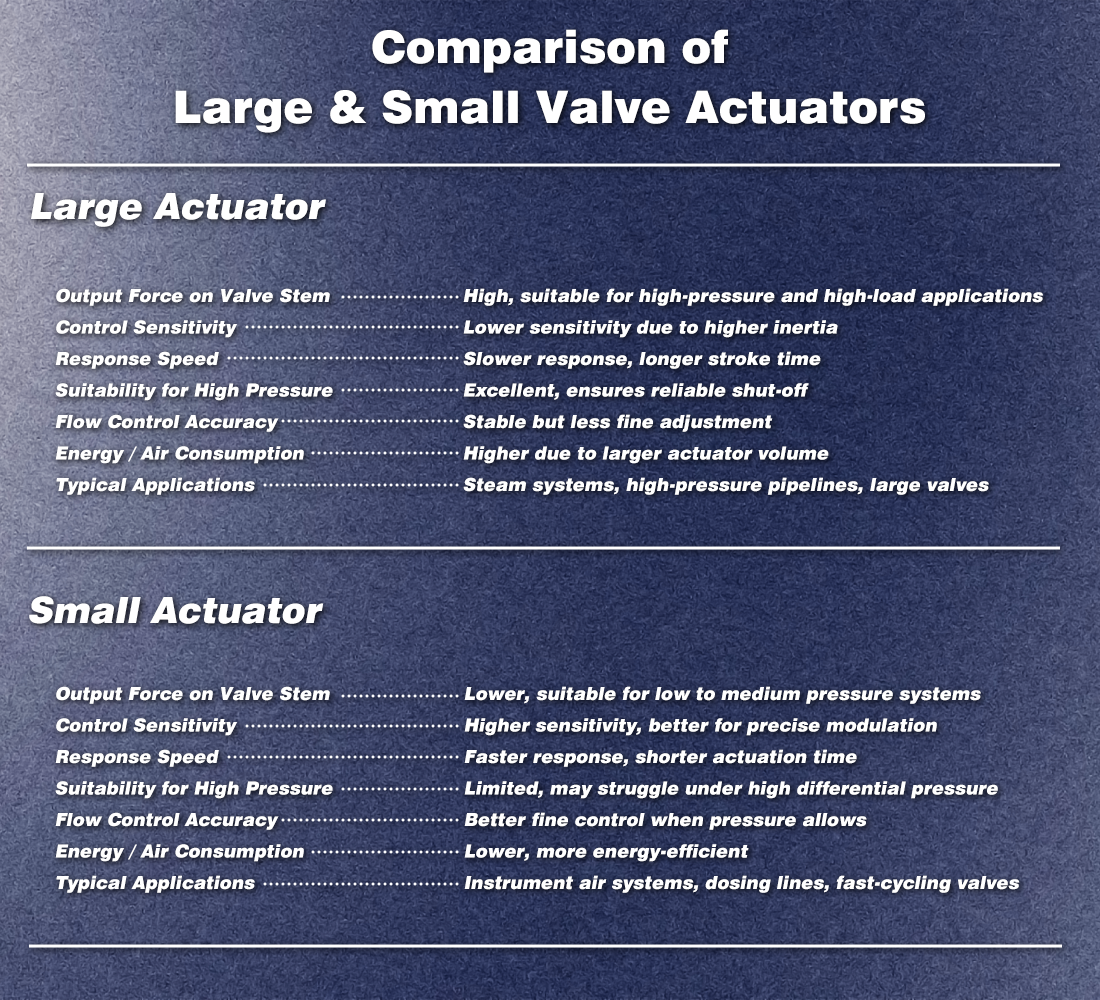

The most noticeable difference between small and large actuators is the output force applied to the valve stem. Larger actuators typically have greater piston or diaphragm areas, allowing them to generate higher thrust or torque. This increased force is especially important in applications involving high line pressure or large valve sizes.

Under high-pressure conditions, process media exert significant opposing force on the valve stem and sealing components. If the actuator output is insufficient, the valve may fail to close fully, resulting in leakage or unstable operation. For this reason, larger actuators are commonly selected for high-pressure applications where reliable shut-off is critical.

While larger actuators provide greater force, they also introduce certain trade-offs. Increased size and mass result in higher inertia, which can slow down valve movement. As a result, larger actuators often respond more slowly than smaller ones under the same control conditions.

In systems that require frequent operation or precise flow control, such as modulating valves or fast-switching processes, an oversized actuator may reduce control accuracy. In contrast, smaller actuators generally offer faster response and higher sensitivity, provided that their output force is sufficient to overcome system pressure and friction.

Actuator sizing should always be based on actual operating conditions rather than choosing the largest possible unit for safety. Different applications demand different performance priorities:

① High-pressure or viscous media systems benefit from larger actuators that can ensure consistent sealing and stable operation.

② High-cycle or fast-response systems are better suited to smaller actuators that improve responsiveness and reduce cycle time.

③ Precision control applications require a balanced approach, ensuring adequate force without sacrificing sensitivity or control stability.

Matching the actuator correctly to the valve and process conditions helps optimize both performance and energy efficiency.

Improper actuator sizing can lead to long-term operational issues. An undersized actuator may struggle to close the valve fully under pressure, increasing the risk of leakage and premature wear. Conversely, an oversized actuator may cause sluggish response, higher air or energy consumption, and unnecessary mechanical stress on valve components.

Additionally, larger actuators require more installation space and may limit flexibility in system layout. These factors should be considered during the design stage to avoid costly modifications later.

In valve automation systems, actuator size alone does not define performance. The optimal actuator is one that matches the valve’s pressure rating, media characteristics, operating frequency, and control requirements. By selecting an actuator that provides sufficient force while maintaining appropriate responsiveness, users can achieve stable, efficient, and long-lasting valve operation.

Understanding how actuator size influences valve behavior is a key step toward improving system reliability and overall control performance.

If you need acuators, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap