Dec 23, 2025

In industrial piping systems, globe valves are widely used not only for on-off control but also for flow regulation. The valve opening, expressed as a percentage of full open flow, is similar to how a faucet is rarely fully opened. Understanding the optimal opening for globe valves is essential to ensure system efficiency, valve longevity, and stable control performance.

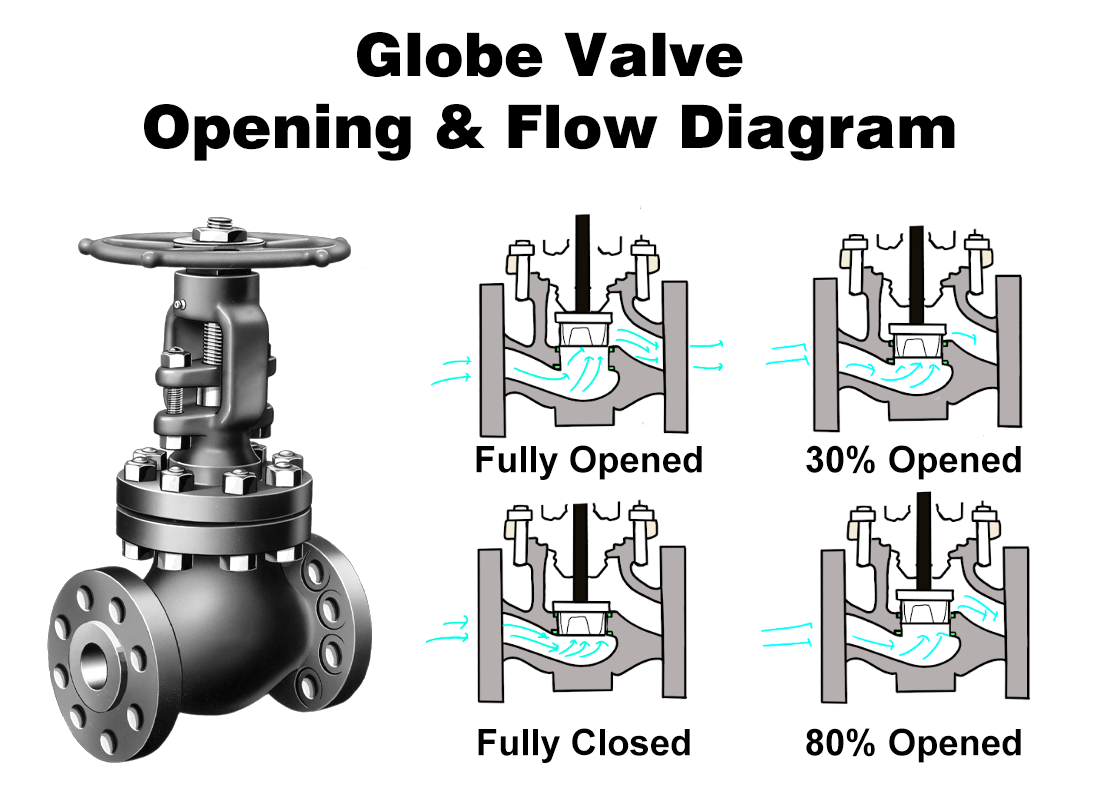

Globe valves are throttling valves, and their flow is not linearly proportional to valve opening. Small changes in stem position can result in significant flow variations, while near full open, additional opening causes relatively minor flow increase. Therefore, the valve opening directly affects the precision of flow control.

Maintaining an appropriate opening ensures that flow changes remain within a controllable range, preventing excessive pressure fluctuations or flow overshoot. Studies and practical experience suggest that globe valves perform best when operated between 30% and 80% opening, balancing flow control effectiveness and minimizing wear on the stem and seat.

Narrow flow passage increases velocity, leading to localized erosion and noise.

High pressure drop concentrates force on the valve stem and seat, accelerating wear or causing stem bending.

Extremely sensitive regulation may result in unstable flow from minor adjustments.

Valve is nearly fully open, making flow control less responsive.

Prolonged near-full open operation can cause slight friction or imperfect sealing, increasing leakage risk.

Full open position cannot fully utilize the valve’s throttling capabilities in modulating systems.

Maintaining 30%-80% opening is therefore considered best practice, balancing flow control, valve life, and system stability.

Valve selection should account not only for diameter, pressure rating, and material but also for expected system flow and operating opening range:

◆ High flow applications: Choose a valve with a flow coefficient (Cv) sufficient to meet requirements even near full open.

◆ Fine control applications: Ensure most operating flow is within the 30%-80% range, avoiding extreme open or close positions.

◆ Systems with significant pressure fluctuations: Consider non-linear effects of opening on flow and pressure, leaving a margin for safe regulation.

By evaluating how opening affects flow, engineers can prevent unstable operation and premature valve wear during design and selection.

In critical industries such as chemical, pharmaceutical, or food processing, globe valve opening is often managed through operational protocols:

① Maintain valve opening within 30%-80% during normal operation to avoid excessive wear or unstable flow.

② In automated systems, use position indicators to monitor and control valve opening within the desired range.

③ Perform periodic inspection of valve seats and stems, adjusting or maintaining as needed to ensure consistent performance.

These practices show that proper opening management impacts not only flow but also valve lifespan and system safety.

The optimal opening for a globe valve is not a fixed number but a range determined by system flow requirements and valve characteristics. Maintaining 30%-80% opening maximizes throttling performance while minimizing stem and seat wear. Considering valve opening during selection and system design helps achieve efficient, stable, and reliable piping system operation.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap