Dec 24, 2025

In industrial piping systems, valves play a critical role in controlling fluid flow, ensuring operational safety, and maintaining process stability. Different types of industrial valves are designed for specific functions and operating conditions. Understanding the characteristics of commonly used valves helps engineers and users make informed decisions during system design and valve selection.

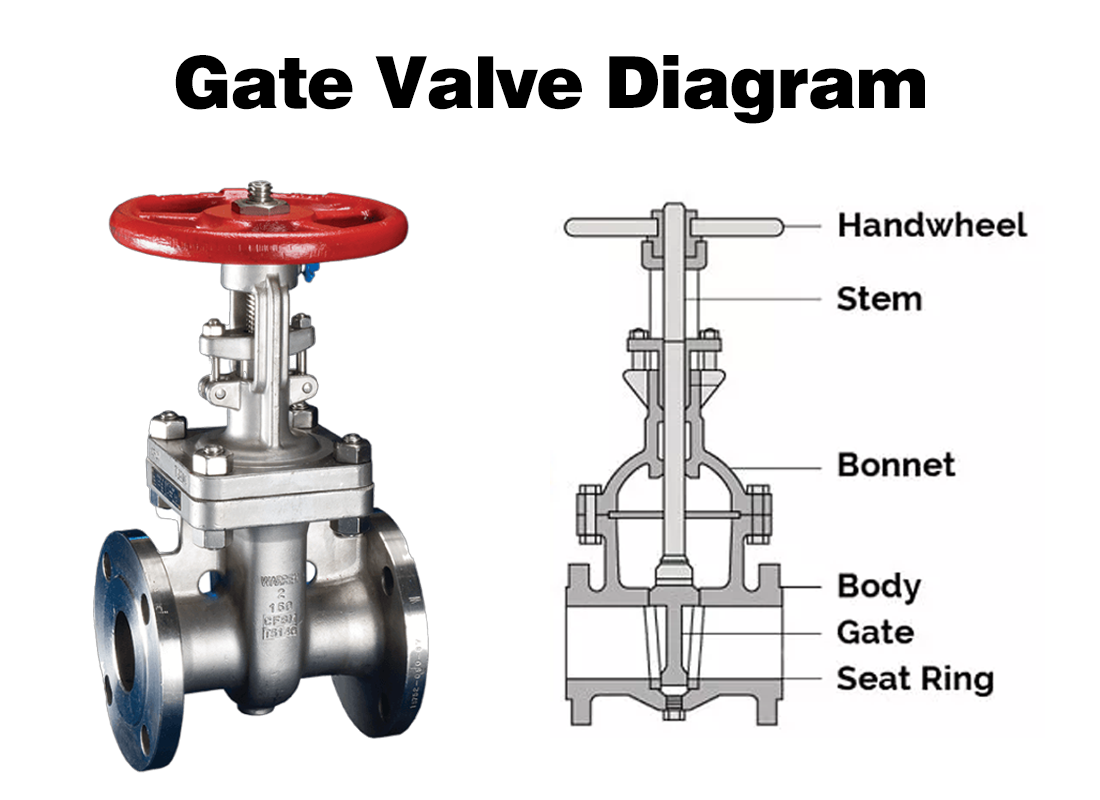

Gate valves are primarily used for isolating flow rather than regulating it. Their design features a gate that moves vertically to block or allow flow. When fully open, the flow path is nearly straight, resulting in minimal pressure loss.

Because of this design, gate valves are well suited for applications where the valve remains either fully open or fully closed for long periods. However, operating a gate valve in a partially open position can cause erosion of the gate and seats due to high-velocity flow. Gate valves are commonly found in water supply systems, oil and gas pipelines, and other large-scale industrial installations.

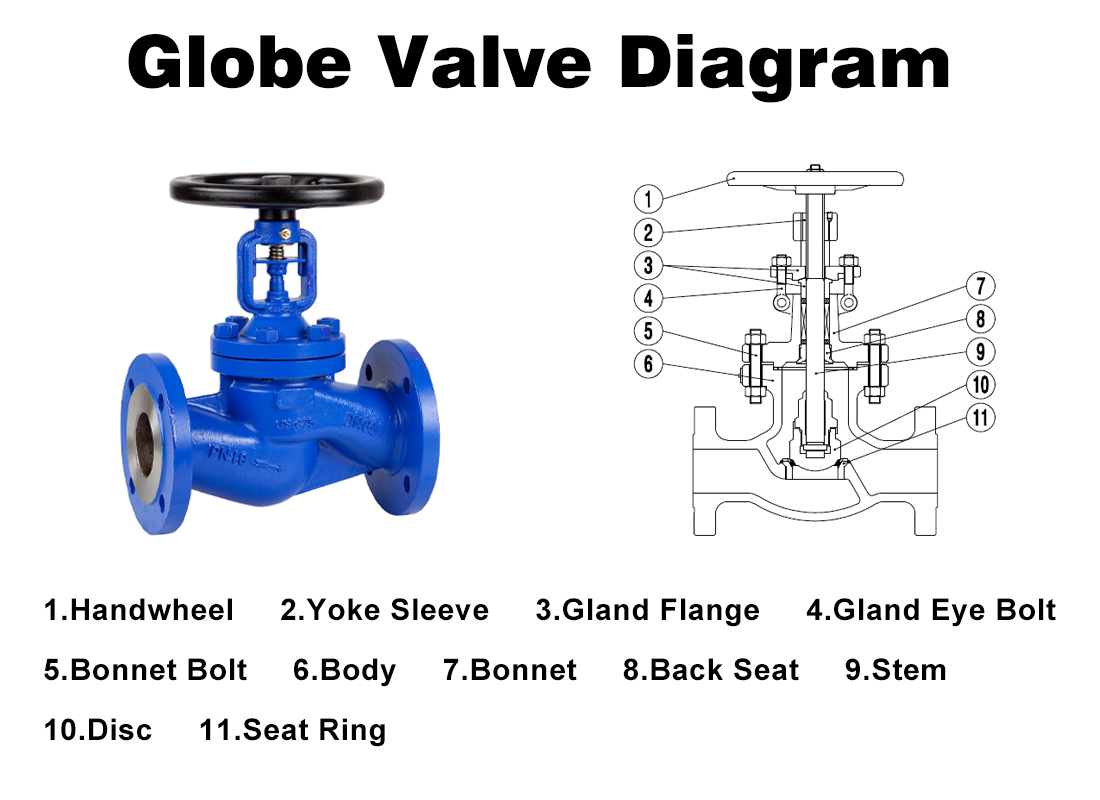

Globe valves are widely used in industrial systems where flow regulation is required. The valve disc moves along the stem axis, allowing precise control of the flow rate by adjusting the opening between the disc and the seat.

Although globe valves create higher pressure drop compared to gate valves, they offer better throttling capability and sealing reliability. They are frequently used in steam systems, chemical processing, and thermal pipelines where controlled flow and frequent operation are necessary.

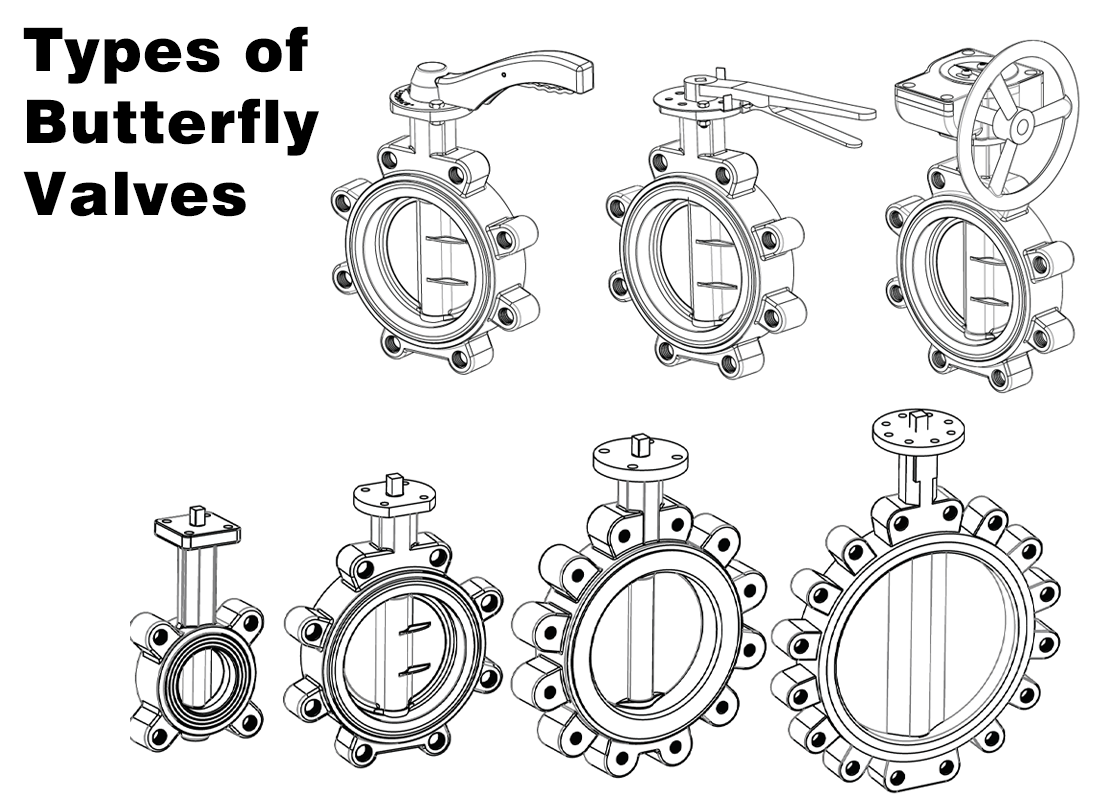

Butterfly valves use a rotating disc to control flow and are known for their compact structure and lightweight design. They require less installation space and are cost-effective, especially in large-diameter applications.

With fast opening and closing speed, butterfly valves are suitable for systems that require quick isolation. While their flow control capability is moderate, they perform well in low to medium pressure systems such as water treatment plants, HVAC systems, and general industrial piping.

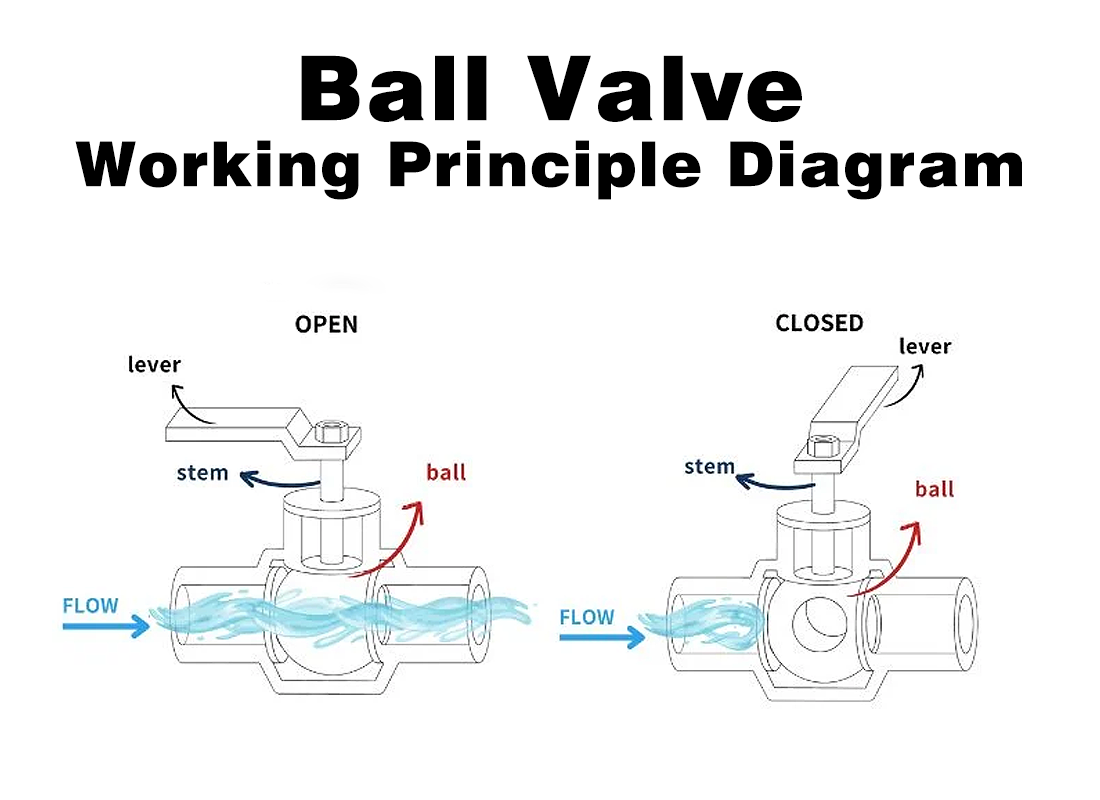

Ball valves feature a spherical ball with a through-hole that rotates 90 degrees to open or close the valve. This simple operation allows rapid shut-off and reliable sealing, even after long periods of inactivity.

Ball valves provide very low flow resistance when fully open, making them ideal for applications that require high flow capacity and tight shut-off. They are widely used in oil and gas, chemical, food, and pharmaceutical industries. However, ball valves are generally not recommended for fine flow control due to their non-linear flow characteristics.

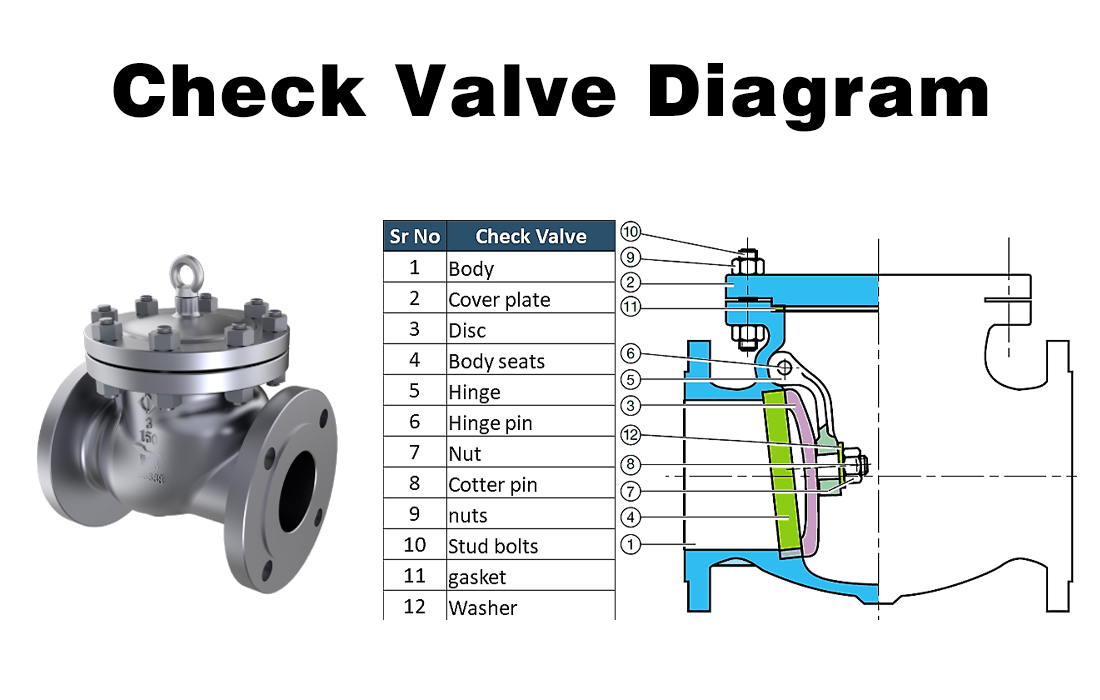

Check valves are designed to prevent reverse flow in piping systems, protecting pumps and other equipment from damage. They operate automatically, opening with forward flow and closing when flow reverses.

There are several types of check valves, including lift check valves and swing check valves, each suited to different flow conditions. Installed commonly at pump outlets or critical pipeline points, check valves are essential safety components in industrial systems.

Selecting the appropriate valve type requires careful consideration of multiple factors rather than focusing on a single feature. Key selection criteria include:

◆ Type of fluid (liquid, gas, steam, or corrosive media)

◆ Operating pressure and temperature

◆ Need for flow regulation or on-off control

◆ Frequency of operation

◆ Installation space and maintenance requirements

For example, butterfly valves are well suited for large-diameter, low-pressure systems, while ball valves and globe valves are preferred where tight sealing is critical. Understanding the strengths and limitations of each valve type ensures reliable performance and long-term system stability.

If you're interested in our products, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Nov 21, 2025 Blog

How to determine valve seat angleFOKCA ©1998-2025 All Rights Reserved Sitemap