Jan 08, 2026

During project procurement, it is common to encounter the idea of using a single valve type to simplify system design and inventory management. Since a globe valve can both shut off and regulate flow, some assume it could replace ball valves entirely. In practice, this approach often leads to higher energy consumption, slower response, and unnecessary costs.

While globe valves excel in flow control applications, they are not a universal substitute. Understanding the differences in pressure drop, cost, and opening speed helps engineers make informed decisions instead of blind replacements.

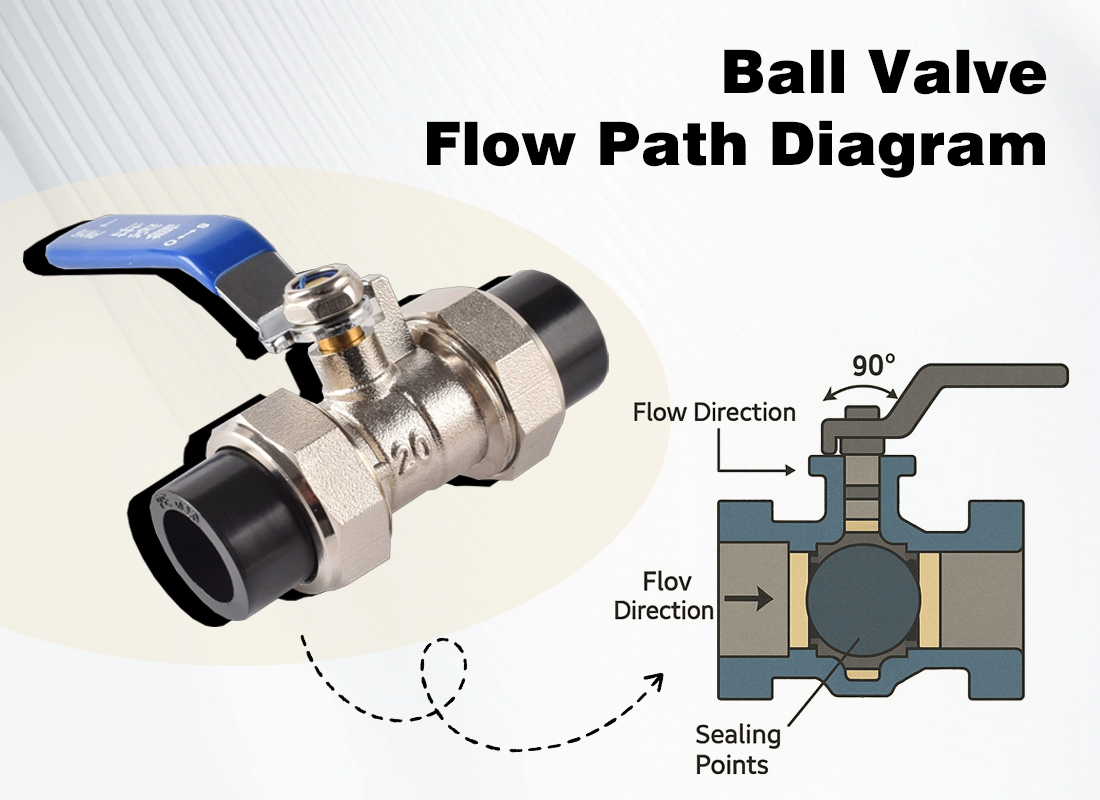

Ball valves feature a near-straight flow path. When fully open, fluid passes with minimal resistance, resulting in very low pressure drop. This makes ball valves ideal for large flow rates and energy-efficient piping systems.

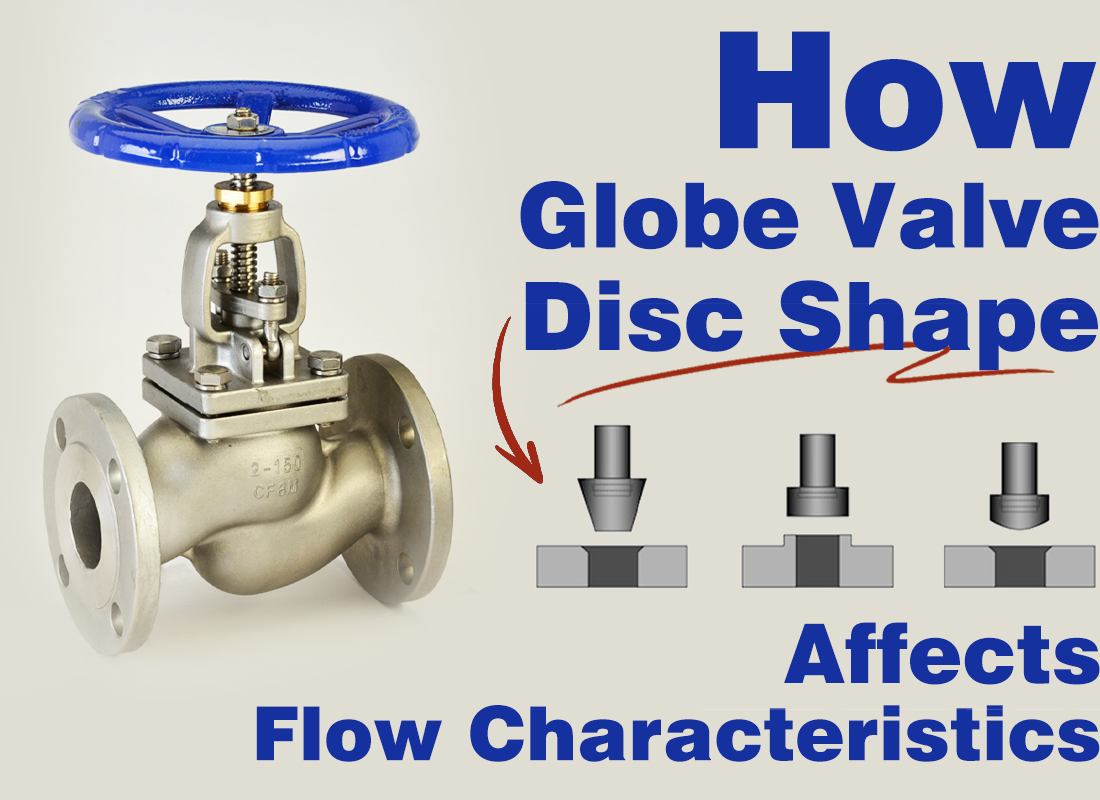

In contrast, a globe valve forces fluid to change direction and pass through a throttling zone between the disc and seat. This inherently creates higher pressure loss. While beneficial for flow control, it becomes a disadvantage in pure on/off or transport lines.

Replacing ball valves with globe valves in main pipelines often increases system resistance and operating energy costs without functional benefit.

From a purchasing perspective, globe valves usually cost more than ball valves of the same size. Their internal structure is more complex, requiring tighter machining tolerances and more material.

Beyond initial cost, operating cost matters. Using globe valveswhere regulation is unnecessary results in continuous pressure loss and higher energy consumption. Additionally, internal components experience ongoing wear under throttling conditions, increasing maintenance frequency.

In lifecycle terms, replacing ball valves with globe valves can significantly raise total ownership cost.

Ball valves operate with a simple 90-degree rotation, enabling fast opening and closing. This makes them suitable for emergency shutoff and safety interlock systems.

Globe valves rely on linear stem movement and longer travel. Even with pneumatic or electric actuators, their response time is slower. While this controlled movement is beneficial for regulation, it may be unsuitable for applications requiring rapid isolation.

Using globe valves in place of ball valves in such systems can compromise responsiveness and safety margins.

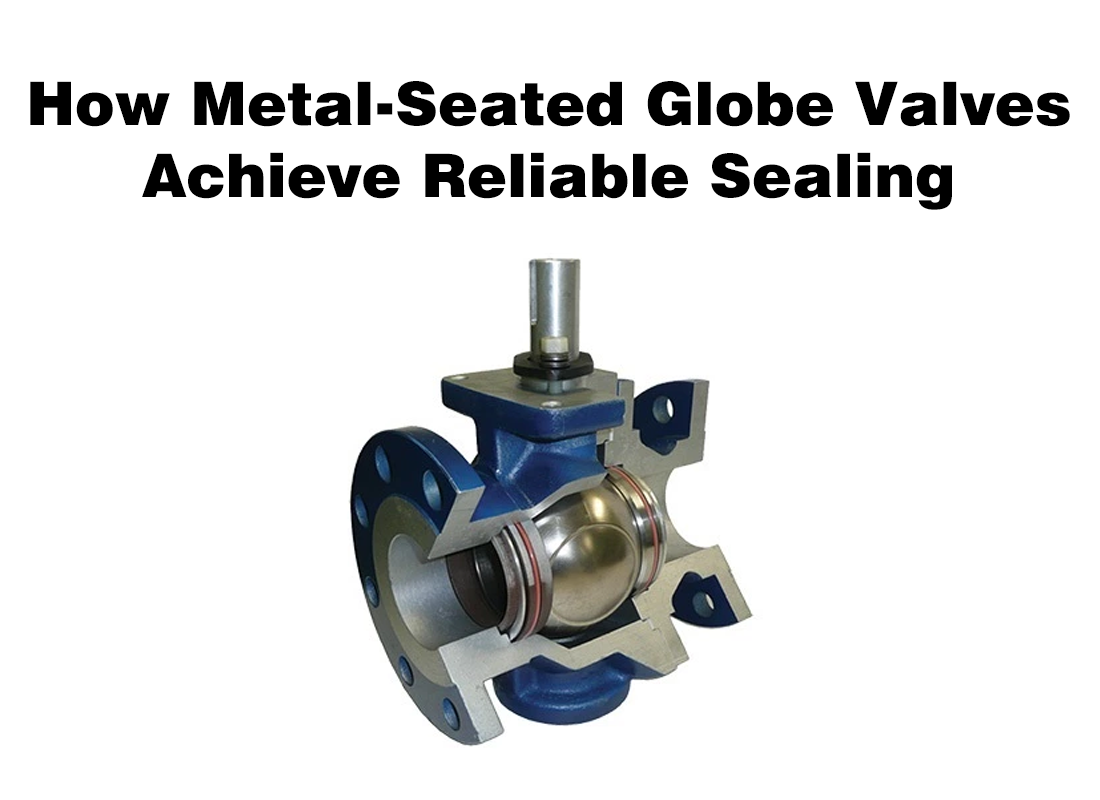

The primary advantage of globe valves lies in their predictable flow characteristics and stable modulation at partial openings. They perform exceptionally well in control loops with fluctuating pressure.

However, many pipelines are designed solely for fluid transmission, not control. In these cases, ball valves offer lower resistance, faster actuation, and simpler construction with excellent reliability.

Proper valve selection is about functional suitability, not feature count.

Well-designed industrial systems often use both valve types strategically:

◆ Globe valves in control lines requiring throttling and stability

◆ Ball valves in main lines, isolation points, and fast-acting applications

This approach allows each valve to operate within its optimal range, improving reliability and reducing long-term costs.

Effective engineering design prioritizes matching valve characteristics to application needs, rather than forcing one solution everywhere.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap