Dec 16, 2025

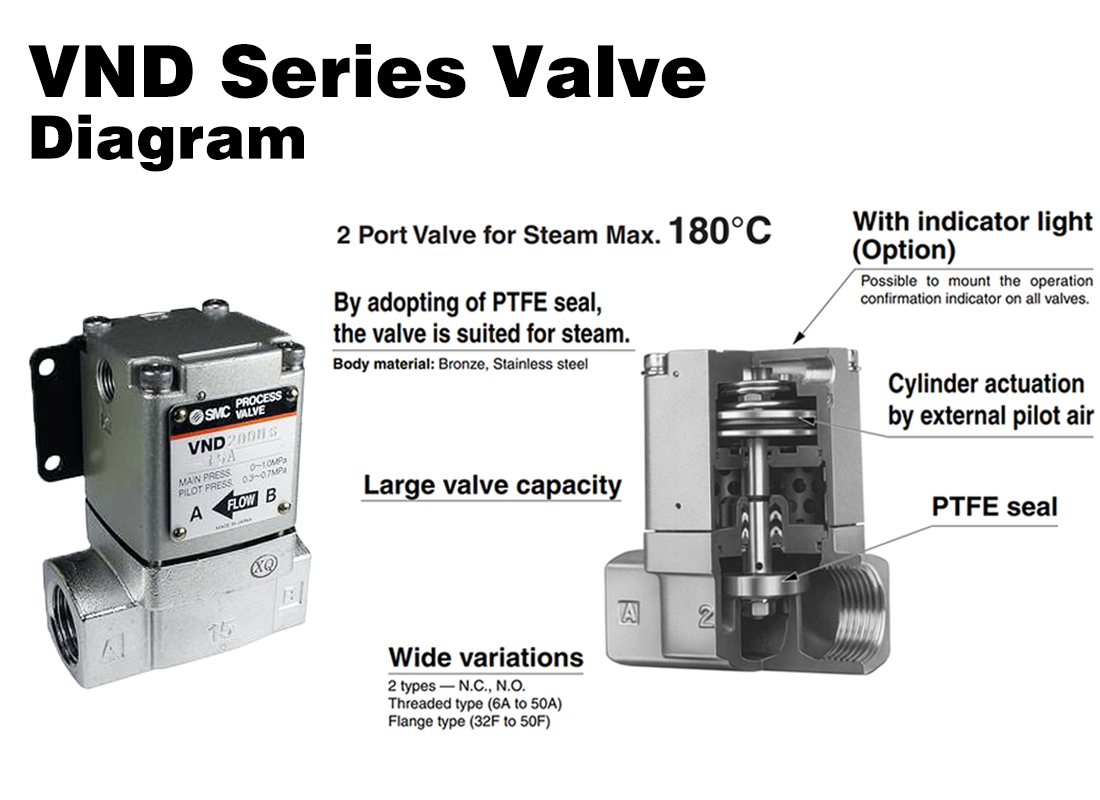

Selecting valves for steam systems is never as simple as allowing flow. High temperatures, corrosive environments, and frequent thermal cycling place heavy demands on both valve structure and sealing materials. When the wrong valve is used, minor leakage can quickly turn into operational instability or safety risks. This is why the VND series steam valve, designed specifically for steam service, is widely applied in food processing, pharmaceuticals, packaging, and chemical industries.

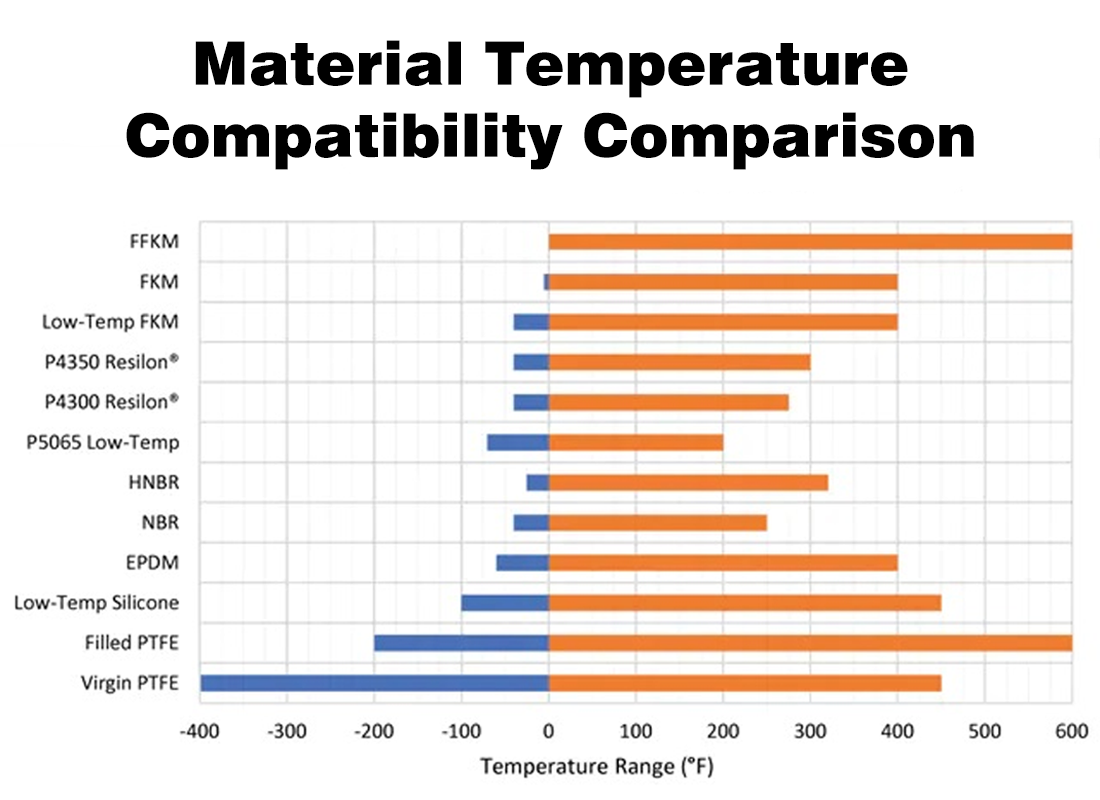

Many steam-related failures are not caused by insufficient valve strength, but by seal materials that cannot withstand sustained high temperatures. Conventional elastomer seals begin to harden or degrade around 120°C, leading to internal leakage, external seepage, or even valve sticking.

Steam systems also experience frequent start-stop cycles, generating condensate and thermal shock, which further accelerates seal wear and structural fatigue.

| Comparison Aspect | VND Series Steam Valve | Standard Fluid Control Valve |

|---|---|---|

| Primary Sealing Material | PTFE seal | NBR, EPDM, or other engineering elastomers |

| Operating Temperature Range | -5°C to 180°C | Typically ≤120°C |

| High-Temperature Resistance | Designed for long-term steam exposure without deformation or aging | Elastomer seals tend to harden and fail under steam |

| Corrosion Resistance | Excellent resistance to steam, scale, and cleaning agents | More susceptible to chemical and thermal degradation |

| Suitable Media | Steam, hot water, selected process fluids | Water, air, and low-temperature fluids |

| Internal Flow Design | Optimized for steam flow, minimizing condensate buildup | General-purpose flow path, prone to condensate issues |

| Maintenance Frequency | Low, suitable for continuous operation | Higher, frequent seal replacement required |

| Operational Risk | Stable and reliable under steam conditions | Higher leakage risk in steam applications |

The defining feature of the VND series steam valve is its PTFE (polytetrafluoroethylene) seal, replacing common rubber-based materials. PTFE is well recognized in industrial fluid control, and its advantages become especially evident in steam applications.

First, thermal stability. The VND series operates reliably within a temperature range of -5°C to 180°C, covering most industrial steam systems. PTFE maintains dimensional stability even under continuous heat, resisting hardening, deformation, or carbonization.

Second, excellent chemical resistance. Steam systems often involve fluctuating water quality, cleaning chemicals, or residual process media. PTFE withstands these conditions without degradation, ensuring long-term sealing performance.

Beyond materials, the internal structure of the VND series is engineered with steam behavior in mind. The streamlined flow path reduces areas where condensate can accumulate, helping to minimize water hammer and pressure fluctuations.

In real-world operation, this design improves reliability during frequent actuation and reduces localized thermal stress that can damage seals in conventional valves.

For equipment requiring stable steam on/off control—such as sterilizers, steam-heated jackets, or branch line isolation—these steam-specific structural advantages become increasingly valuable over time.

Even when the correct steam valve is selected, problems can still arise if standard pneumatic or water fittings are used in the system. High-temperature steam quickly deteriorates seals not designed for heat, leading to leaks and potential safety hazards.

When installing a VND series steam valve, it is essential to use steam-rated pipes and fittings, such as metal connectors or components explicitly specified for steam service. This should be considered during system design rather than addressed after failures occur.

The VND series is commonly used in:

◆ Steam sterilization and heating in food and beverage processing

◆ Steam-in-place (SIP) systems in pharmaceutical equipment

◆ Industrial steam heating circuits

◆ Temperature control and steam-driven functions in packaging machinery

During selection, attention should be given not only to port size and connection type, but also to actual steam temperature, operating pressure, and actuation frequency. For systems with frequent cycling or sustained high temperatures, a dedicated steam valve often delivers better long-term reliability and cost efficiency than a general-purpose alternative.

The stability of a steam system often depends on details that are easy to overlook. By combining PTFE sealing, steam-adapted internal design, and clearly defined operating limits, the VND series steam valve provides a dependable solution for high-temperature steam control.

In real industrial environments, selecting the right valve and compatible accessories from the outset reduces maintenance, downtime, and long-term operating costs—making correct steam valve selection a critical part of system reliability.

If you need VND series valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap