Dec 17, 2025

In industries such as food processing, chemical production, steam systems, and automation lines, angle seat valves are often regarded as “fit and forget” valves. Even under high-frequency operation or continuous use, they rarely require seal replacement or extra maintenance. This maintenance-free feature is not accidental—it comes from the design of the connection between the valve body and the actuator, which uses a PTFE V-type packing with spring compensation and silicone lubrication.

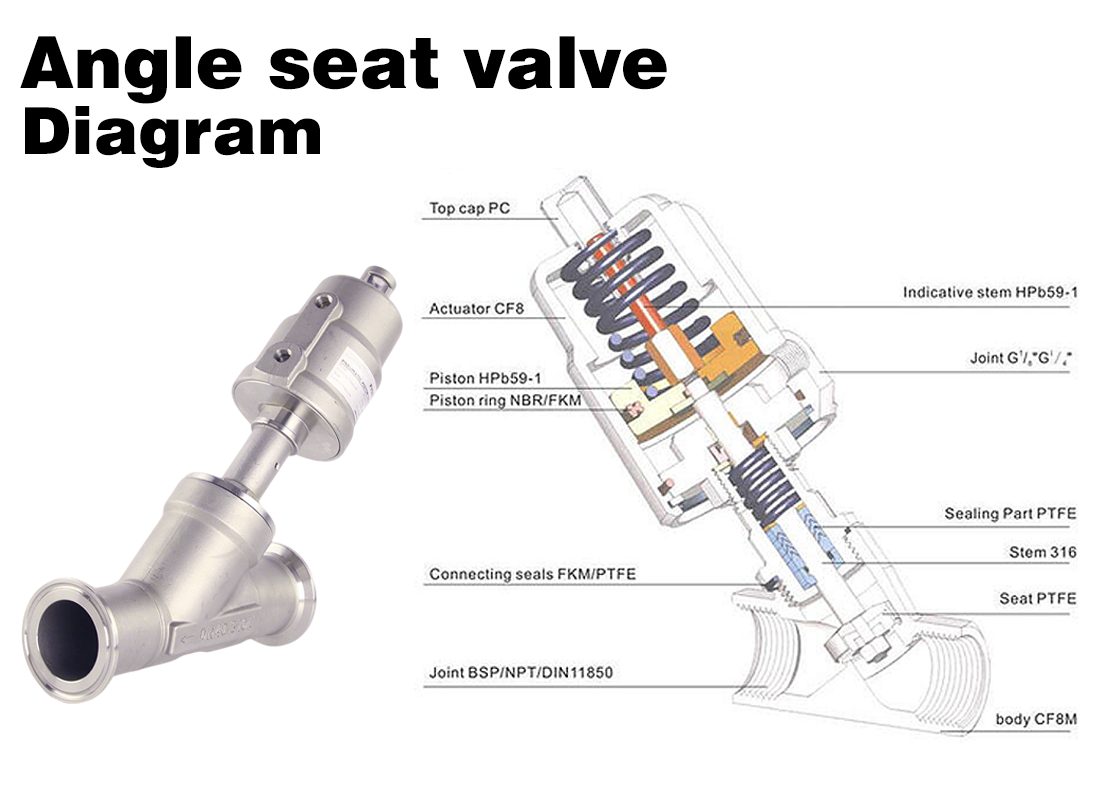

Many focus on the valve seat or stem, but in long-term operation, the area most prone to leakage is the valve stem passing through the valve body. This section must allow high-speed movement of the stem while withstanding system pressure, temperature fluctuations, and medium erosion. Without a stable sealing structure, leakage will inevitably occur.

Angle seat valves solve this problem with a V-type PTFE packing combined with a spring-loaded compensation mechanism, fundamentally addressing wear, loosening, and aging issues.

Unlike ordinary O-rings, the packing used in angle seat valves consists of multiple layers of PTFE V-type packing. Once installed, this packing forms a self-adjusting sealing system that responds dynamically to pressure changes.

Under system pressure, the V-type packing expands outward, closely contacting the valve stem and packing chamber walls. This creates a pressure-tight seal that becomes tighter as pressure increases. Compared to static seals, V-type packing maintains stable contact even under reciprocating motion, significantly reducing leakage risks.

Material alone is not enough for ultra-long service life. Below the V-type packing, angle seat valves incorporate a spring-loaded mechanism that continuously applies axial preload to the packing.

When minor wear occurs over long-term operation, the spring automatically compensates for the displacement, maintaining a stable seal without manual adjustment or replacement. This feature is crucial in high-frequency operations and is a key reason why angle seat valves can operate millions of cycles reliably.

During assembly, a small amount of high-temperature silicone grease is applied to the V-type packing and valve stem. This lubrication does not only provide short-term smoothness but reduces friction over long-term reciprocating motion, minimizing PTFE wear.

Silicone grease also helps isolate moisture and medium residues, slowing down aging and keeping the seal effective for years.

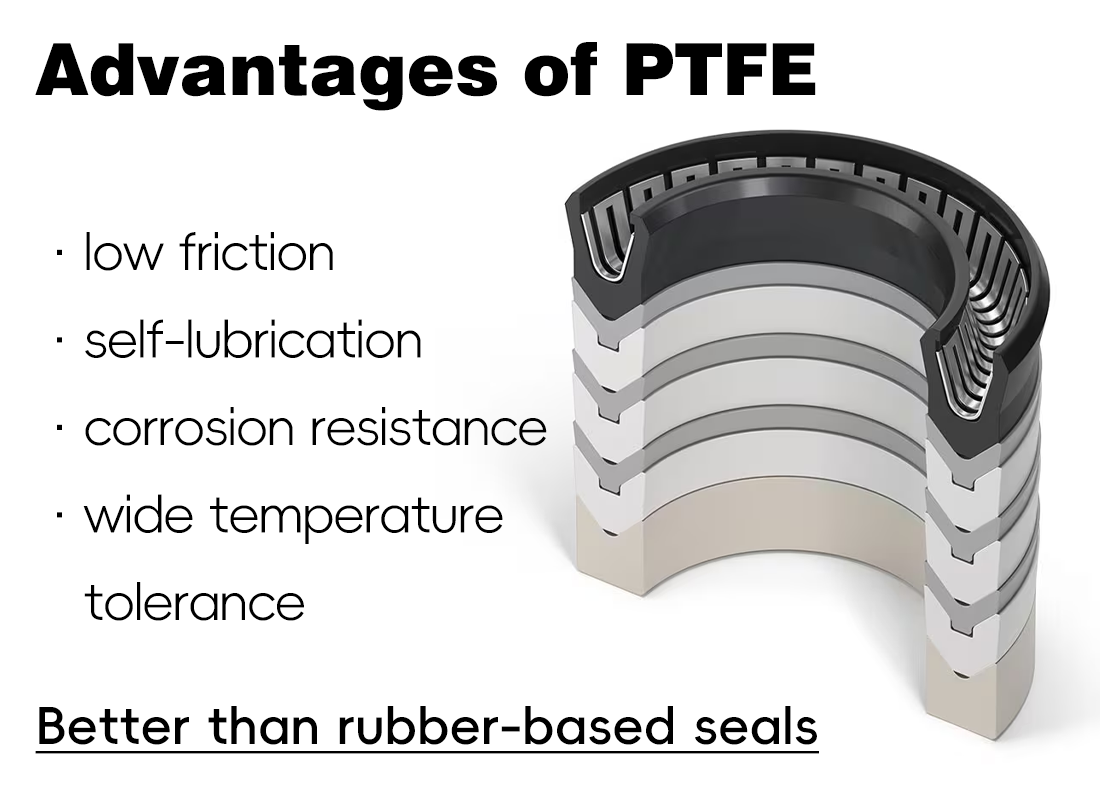

PTFE offers low friction, self-lubrication, corrosion resistance, and wide temperature tolerance, making it ideal for dynamic valve stem sealing. In steam, water, and mild acid/alkaline environments, PTFE maintains dimensional stability far better than rubber-based seals, ensuring extremely low leakage rates over long-term use.

Many standard globe valves or low-quality angle seat valves still rely on single O-ring seals, lacking adaptive compensation. Once wear or thermal expansion occurs, maintenance or replacement becomes unavoidable.

In contrast, PTFE V-type packing + spring compensation + silicone lubrication allows angle seat valves to adapt automatically, providing maintenance-free operation and ultra-long life from a structural perspective.

The widespread use of angle seat valves in automation is not because they “never need maintenance,” but because designers have proactively accounted for wear, temperature, pressure, and long-term operation at critical sealing points. By choosing the right materials and designing adaptive structures, maintenance needs are minimized—this is the essence of reliable industrial valve engineering.

If you need angle seat valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap