Dec 30, 2025

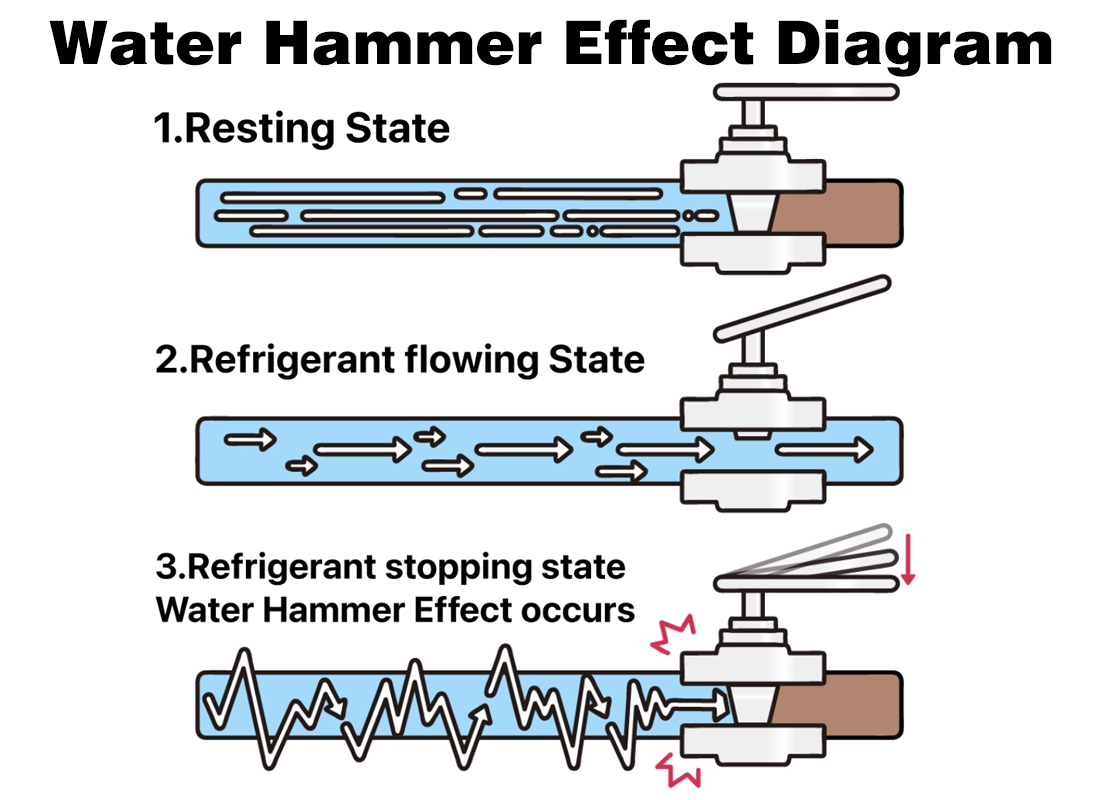

Sudden knocking noises in pipelines during valve operation are often a clear sign of the water hammer effect. This phenomenon occurs when flowing media is abruptly stopped, causing a rapid pressure surge that travels through the piping system. Over time, these pressure spikes can damage valves, pipes, and seals, leading to unplanned downtime.

Water hammer is typically associated with fast valve closing under high flow velocity. The kinetic energy of the fluid is converted into pressure energy almost instantly, generating a shock wave that may exceed normal operating pressure by several times.

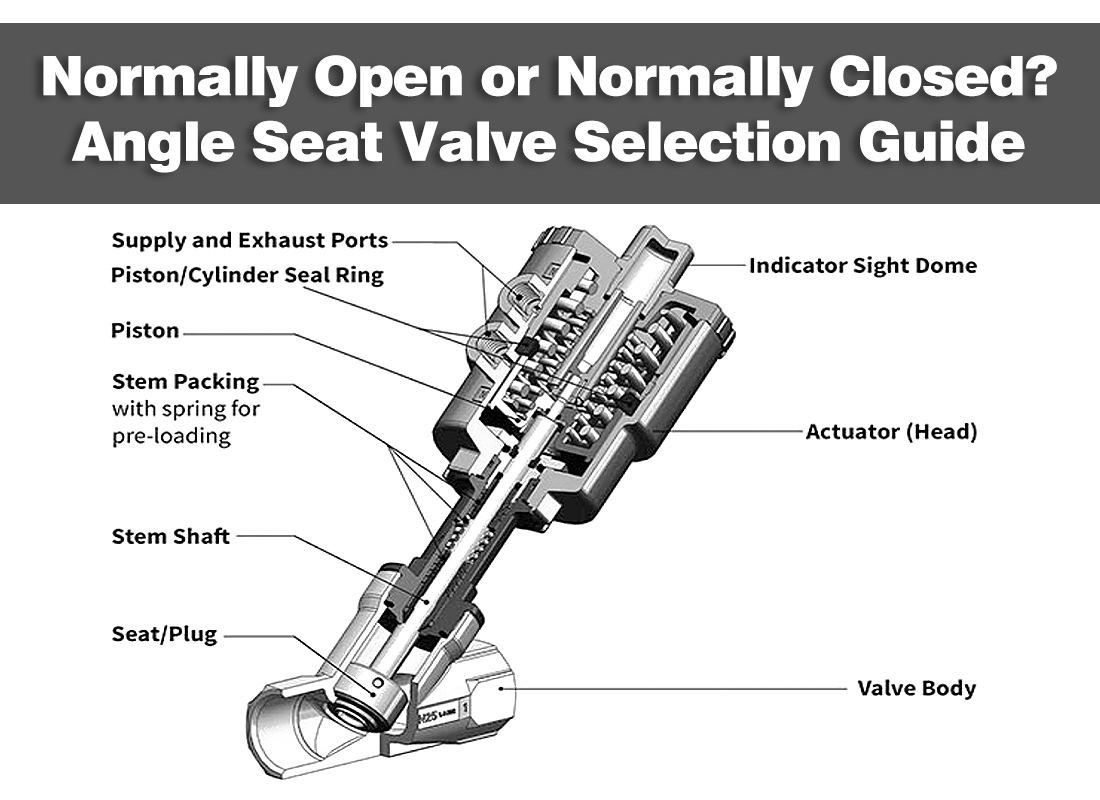

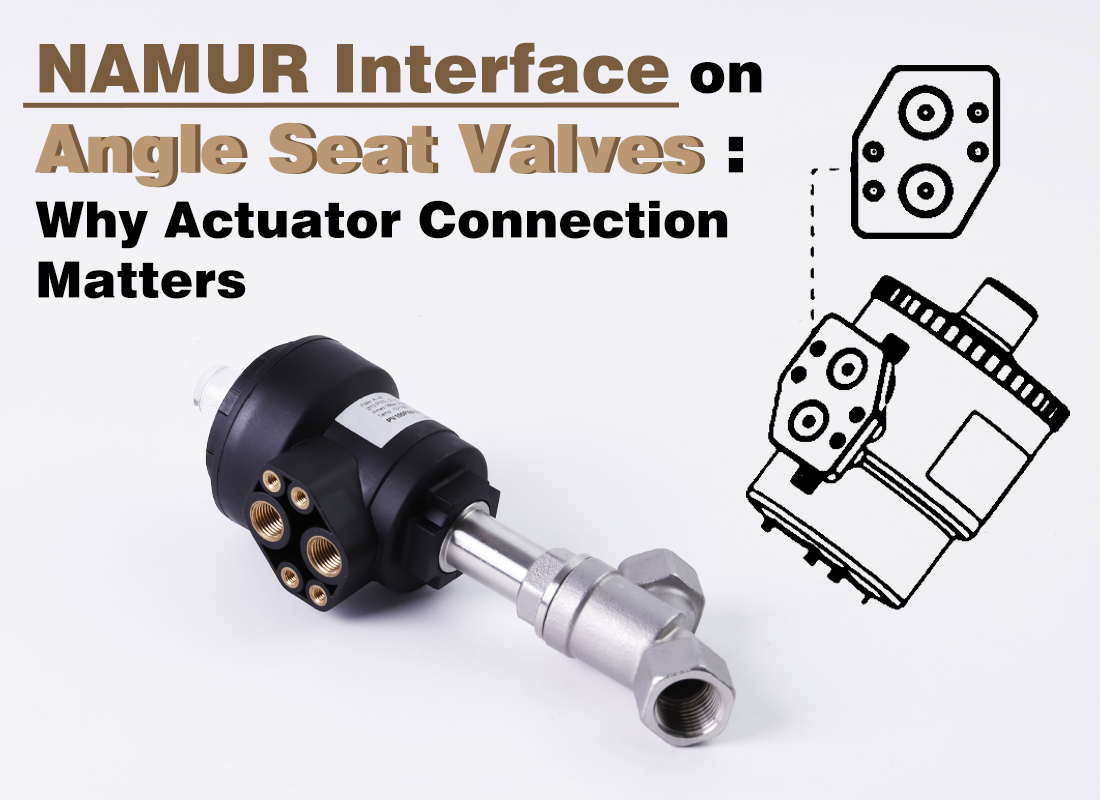

An angle seat valve features a unique flow path where the me dia enters from below the valve seat. This design allows the valve plug to move vertically, enabling a more controlled opening and closing process. Unlike straight-through valves, the flow is not abruptly cut off.

During closing, fluid pressure acts against the valve plug, naturally slowing its movement. This creates a gradual pressure transition, reducing the intensity of pressure spikes and minimizing shock waves inside the pipeline.

Inside an angle seat valve, the fluid changes direction as it passes through the valve body. This redirection dissipates energy and smooths pressure variation. From a fluid dynamics perspective, the rate of pressure change is reduced, which is critical for limiting water hammer damage.

This makes angle seat valves especially suitable for steam systems, condensate lines, and high-speed liquid applications.

Another advantage lies in the axial force direction acting on the valve stem. Axial loading minimizes bending stress, improving stem alignment and reducing wear on seals and actuators. For pneumatic angle seat valves, this results in more stable actuation and longer service life.

Angle seat valves are commonly used in:

① Steam distribution systems

② Beverage and food processing lines

③ Pharmaceutical clean utilities

④ Automated washing and filling equipment

In these environments, controlling water hammer is not just about noise reduction, but about protecting equipment and ensuring process reliability.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap