Dec 29, 2025

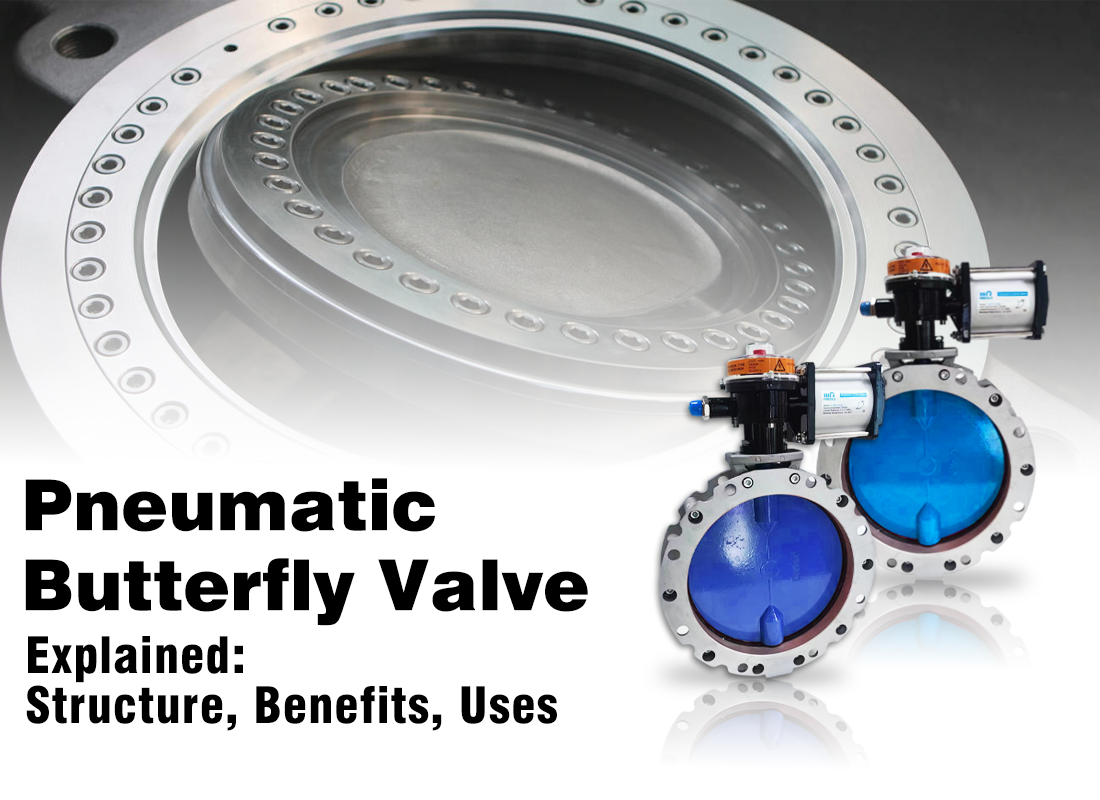

In industrial piping systems, valves do far more than simply open and close a line. They influence response speed, installation space, automation capability, and long-term operating cost. A pneumatic butterfly valve is widely used because it balances these factors effectively. With a compact structure and fast actuation, it is especially suitable for applications that require frequent operation or automated control. Understanding what a pneumatic butterfly valve is—and why it is so commonly selected—helps engineers and system integrators make better decisions during design and maintenance.

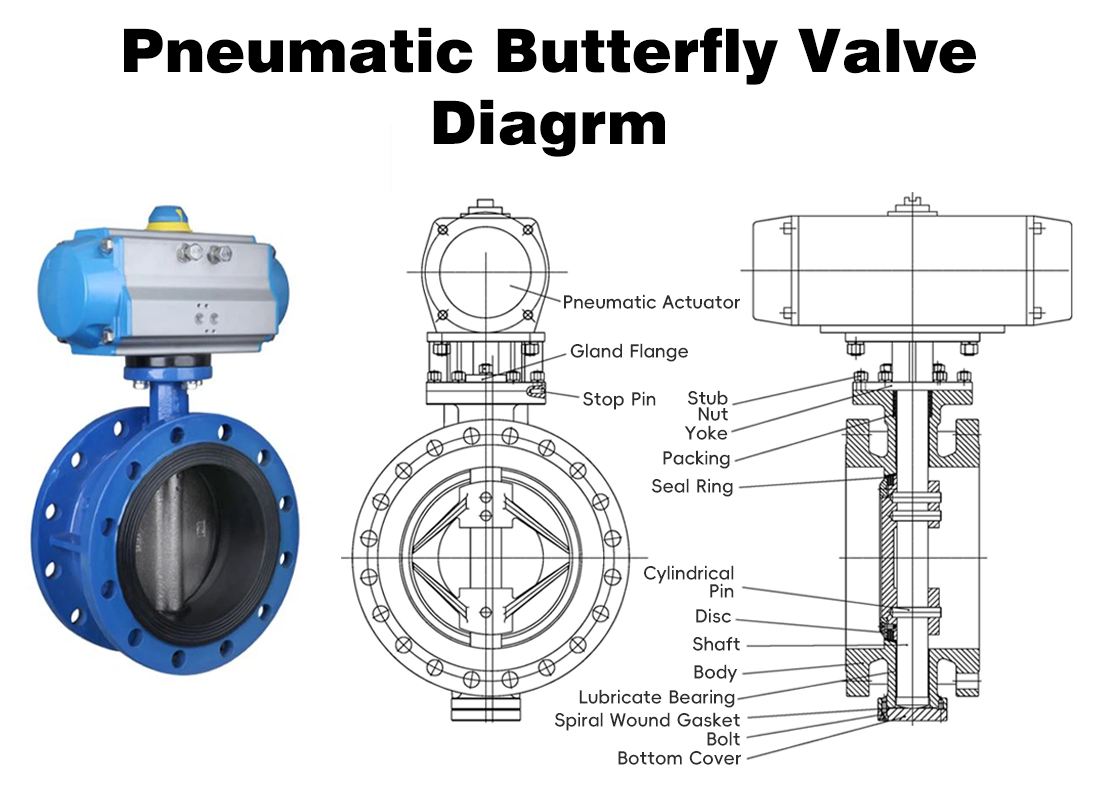

A pneumatic butterfly valve is a quarter-turn valve driven by compressed air through a pneumatic actuator. Its main components include the valve body, butterfly disc, stem, and pneumatic actuator. When compressed air enters the actuator, it generates rotational torque that turns the stem, causing the disc to rotate inside the pipeline and control the flow of the medium.

Unlike gate or globe valves that rely on linear movement, butterfly valves operate with a 90-degree rotation. This simple motion allows the valve to move quickly between fully open and fully closed positions, giving butterfly valves a clear advantage in response speed and structural simplicity.

In practical operation, a pneumatic butterfly valve is typically paired with either a double-acting or single-acting actuator. When compressed air is supplied, pistons or vanes inside the actuator rotate, transmitting torque to the valve stem through a coupling. The butterfly disc then rotates, changing the effective flow area within the pipeline.

When the air supply is switched or released, the disc rotates back to its original position. The entire process does not rely on electric motors, which means fewer components, fewer failure points, and higher reliability in demanding industrial environments.

For large-diameter pipelines, valve size and weight directly affect installation difficulty and structural support requirements. Compared with gate or ball valves of the same nominal size, pneumatic butterfly valves have a much thinner body profile and significantly lower weight.

This compact design makes pneumatic butterfly valves easier to install in tight spaces and reduces the load on piping systems. In retrofit projects or dense pipeline layouts, this advantage often becomes a decisive factor during valve selection.

Because only a quarter-turn rotation is required, pneumatic butterfly valves offer rapid opening and closing times. In automated production lines, consistent and fast valve response is critical. When combined with solenoid valves, positioners, or limit switches, pneumatic butterfly valves integrate seamlessly into PLC or DCS systems for remote and centralized control.

For applications with frequent cycling, pneumatic actuation provides stable performance without the heat buildup or wear commonly associated with electric motors.

When fully open, the butterfly disc aligns nearly parallel to the direction of flow, resulting in relatively low pressure loss across the valve. This makes pneumatic butterfly valves well-suited for large flow rates, particularly in water, air, and other low-viscosity fluids.

Although butterfly valves are not designed for precise flow regulation, they perform well in applications that require on-off control or coarse flow adjustment with minimal energy loss.

Pneumatic butterfly valves are available with various sealing designs to match different operating conditions. Soft-seated valves provide excellent sealing performance and are commonly used in low-pressure, ambient-temperature applications. Metal-seated butterfly valves offer higher resistance to temperature, abrasion, and certain corrosive media, making them suitable for steam or particle-containing fluids.

This flexibility allows pneumatic butterfly valves to be adapted to a wide range of industrial environments, from general utilities to selected chemical processes.

From a maintenance perspective, pneumatic butterfly valves are relatively easy to service. Their internal structure is straightforward, and the number of wear parts is limited. Routine maintenance typically focuses on seals and the air supply system rather than complex internal mechanisms.

Over the full lifecycle of a system, maintenance time and replacement costs remain predictable, which is especially important in installations with a large number of valves operating simultaneously.

Thanks to their structural and operational advantages, pneumatic butterfly valves are widely used in water supply and drainage systems, compressed air lines, HVAC installations, food processing equipment, and certain chemical processes. In these applications, the priority is reliable and fast on-off control rather than ultra-precise flow modulation.

Understanding the structure, benefits, and typical uses of pneumatic butterfly valves helps engineers select a solution that balances performance, reliability, and cost. While no single valve type fits every application, pneumatic butterfly valves remain a practical and efficient choice wherever compact design, fast actuation, and automated operation are required.

If you need pneumatic butterfly valves, you can contact us directly.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap