Dec 18, 2025

A shuttle valve, also known as an executing OR logic pneumatic valve, is a fundamental component in pneumatic control systems. Its core function is to compare two input pressures and output the higher one, enabling efficient control in automation circuits. This simple yet powerful logic mechanism is widely used in industrial automation, machinery, and safety systems.

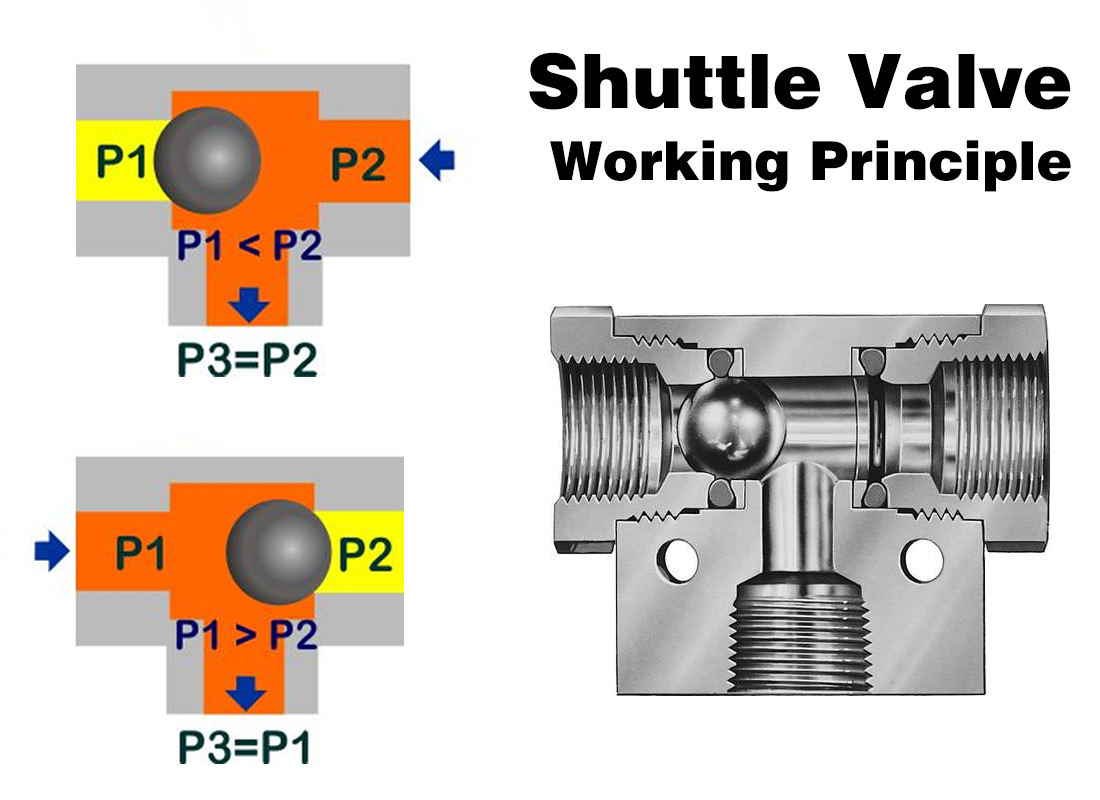

The operation of a shuttle valve relies on a steel ball inside the valve body, as illustrated in the diagram above. The valve has three ports: two inputs and one output. When pressure is applied to either input, the steel ball shifts to block the lower-pressure side, allowing the higher-pressure air to pass through to the output.

For example, if the left input pressure exceeds the right, the ball is pushed to the right, blocking the right port. In this state, the left input port communicates directly with the output port, ensuring that the higher pressure is transmitted efficiently. Conversely, if the right input pressure is higher, the ball moves to block the left port, connecting the right input to the output.

When both input pressures are equal, the valve is designed to allow the output port to connect with the port that receives air first. This ensures deterministic behavior in timing-critical pneumatic circuits.

① OR Logic Functionality: A shuttle valve essentially performs an OR logic operation in pneumatic systems. It outputs the higher of the two input signals, making it useful in scenarios where multiple pressure sources need to be prioritized.

② Automatic Pressure Comparison: The steel ball mechanism automatically compares pressures without the need for electrical sensors or controllers. This passive operation improves reliability and reduces complexity.

③ Fail-Safe Operation: By ensuring that the higher pressure always reaches the output, shuttle valves help maintain stable actuation in emergency or backup pneumatic circuits.

④ Simple Structure and Low Maintenance: The internal design typically includes only a few moving parts, such as the steel ball and spring seats, which makes the shuttle valve durable, easy to maintain, and cost-effective.

Shuttle valves are versatile components widely used in industrial automation and pneumatic control systems.

| Application Scenario | Function of Shuttle Valve | Practical Benefit |

|---|---|---|

| Redundant air supply systems | Selects the higher pressure from two air sources | Ensures continuous operation when one air line fails |

| Pneumatic cylinder control | Combines signals from two control valves | Allows multiple control points for one actuator |

| Emergency stop circuits | Prioritizes emergency air signal | Improves system safety and fail-safe response |

| Vacuum and blow-off systems | Switches between vacuum and compressed air | Enables fast part release and handling efficiency |

| Pneumatic logic circuits | Performs OR logic function | Reduces need for electrical control components |

| Automated packaging machines | Selects active control signal | Improves reliability in high-cycle operations |

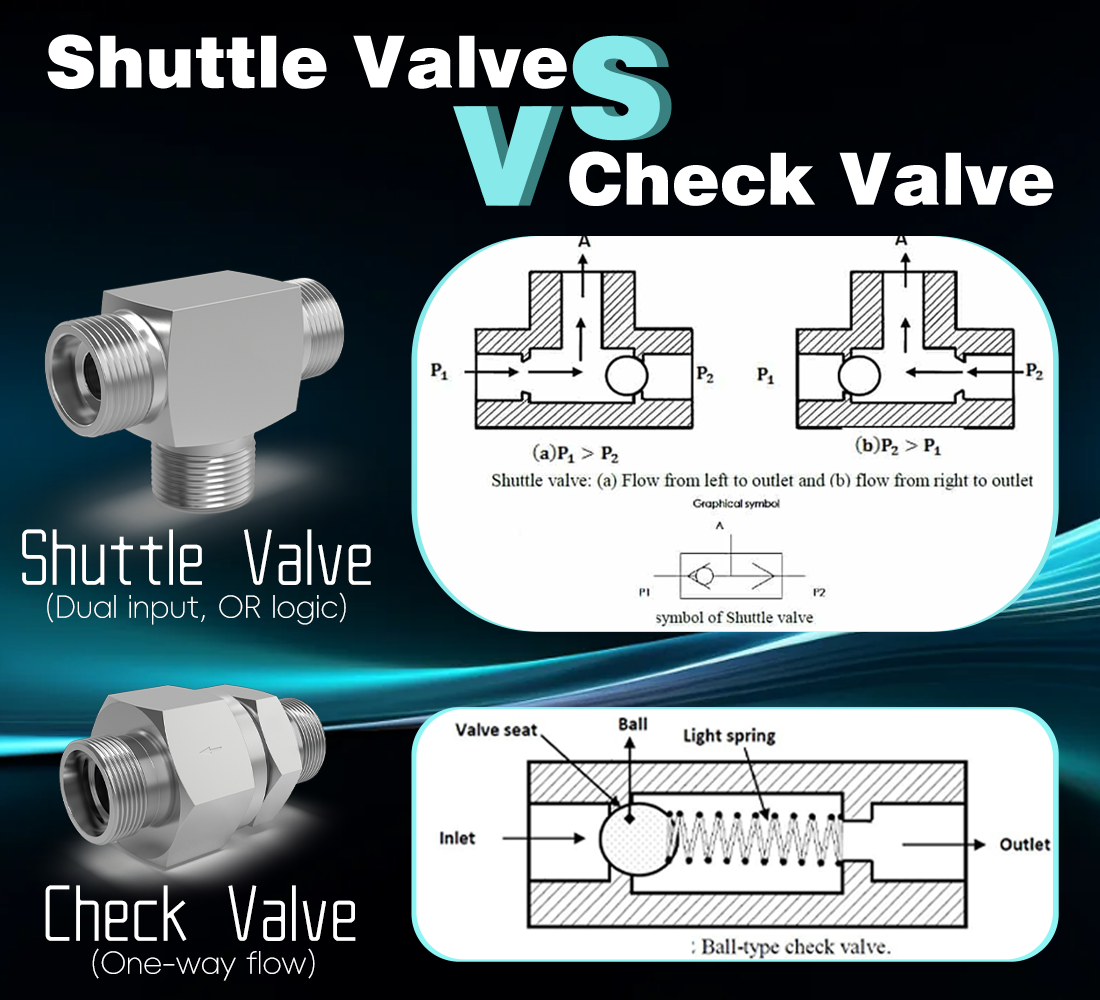

When selecting valves, the working principles of shuttle valves and check valves differ significantly, so engineers need to choose the appropriate type based on application requirements.

When selecting the right shuttle valve, engineers should consider:

◆ Pressure Rating: Ensure the valve can handle the maximum system pressure without leakage.

◆ Material: Steel or stainless-steel balls improve durability in harsh industrial environments.

◆ Port Size: Match the input and output ports with the existing pneumatic tubing to prevent flow restriction.

◆ Response Speed: For high-frequency operations, choose valves with minimal internal friction and lightweight balls for faster switching.

Understanding how a shuttle valve works is crucial for designing reliable pneumatic systems. Its OR logic functionality, pressure comparison mechanism, and robust design make it an indispensable component in modern industrial automation. By correctly selecting and installing shuttle valves, engineers can ensure efficient airflow control, system reliability, and simplified circuit design in a wide range of applications.

If you need shuttle valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Nov 21, 2025 Blog

How to determine valve seat angleFOKCA ©1998-2025 All Rights Reserved Sitemap