Dec 25, 2025

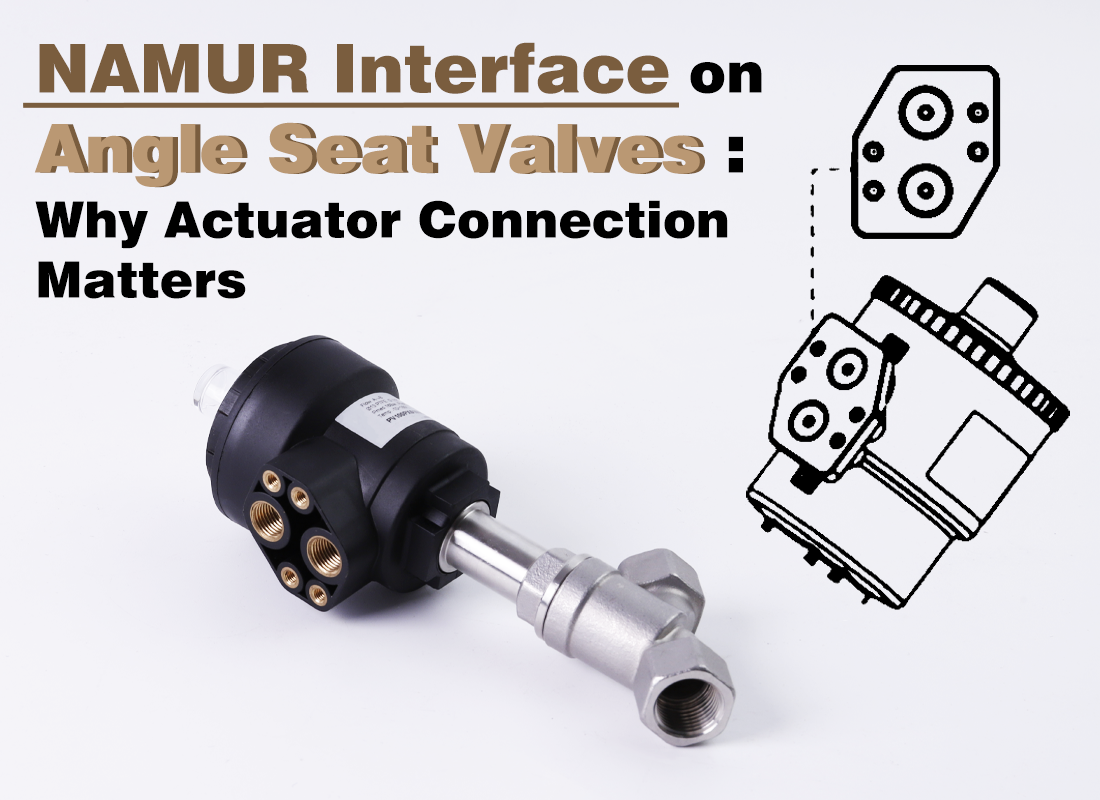

When selecting an actuator for an angle seat valve, many users focus primarily on the actuator material. Models such as P, PX, and PR actuators are all made of nylon, which often leads to the assumption that their performance is largely the same. In practice, however, the way an actuator connects to external control devices can have a far greater impact on system efficiency, installation time, and long-term reliability. This is where the NAMUR interface becomes especially important.

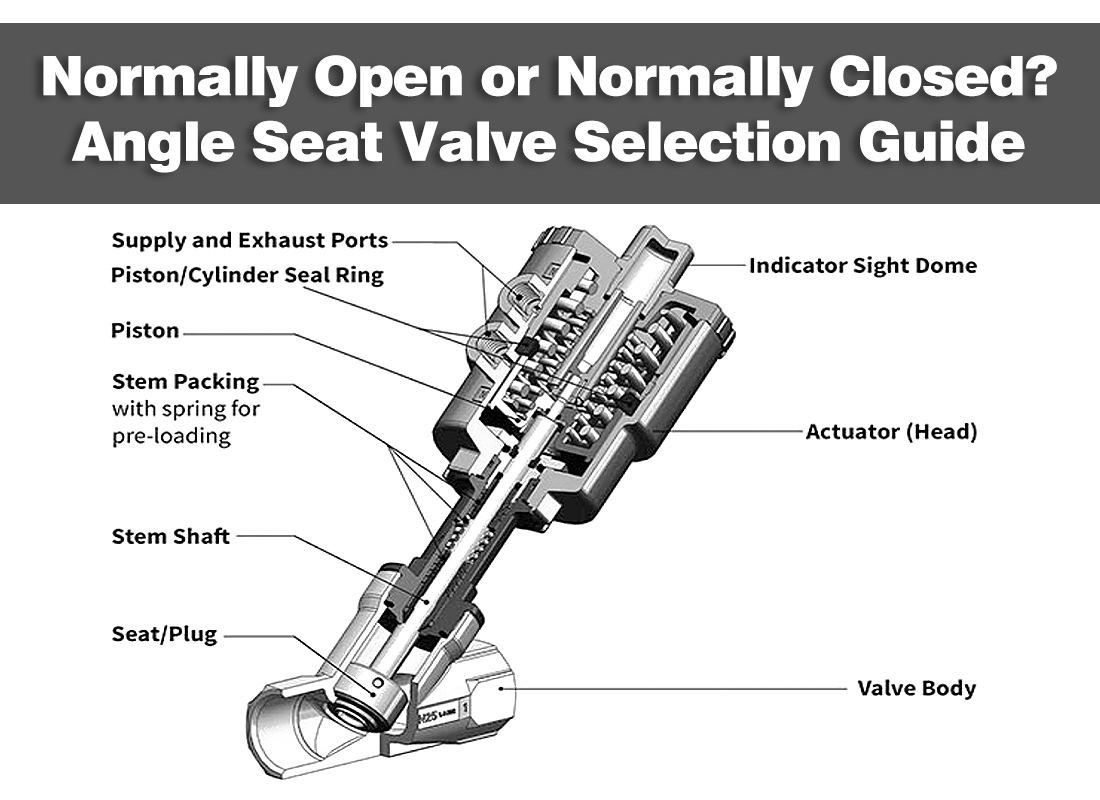

An angle seat valve actuator does more than simply move the valve stem to open or close the valve. It also serves as the interface between the valve and the pneumatic control system, including solenoid valves and air supply components. The actuator’s interface design directly affects how easily a solenoid valve can be installed, how compact the air circuit can be, and how reliably the valve responds to control signals.

In real industrial projects, non-standard actuator interfaces often require additional fittings, tubing, or adapter plates. These extra components increase installation complexity and introduce potential leakage points. As a result, standardized actuator interfaces are increasingly valued in modern automation systems.

From a material perspective, P, PX, and PR actuators share similar characteristics. Their nylon construction provides light weight, corrosion resistance, and good cost performance, making them suitable for applications in food processing, beverage production, and chemical systems. However, the real differences lie in their structural design and connection methods.

| Feature | P Actuator | PX Actuator (NAMUR Type) | PR Actuator |

|---|---|---|---|

| Material | Nylon | Nylon | Nylon |

| NAMUR Interface | No | Yes (Standard NAMUR) | No |

| Solenoid Valve Mounting | External mounting with tubing | Direct mounting on actuator | External mounting with tubing |

| Pneumatic Connection | External air hoses required | Integrated air passages | External air hoses required |

| Installation Complexity | Medium | Low | Medium |

| Response Time | Standard | Faster due to shorter air path | Standard |

| Leakage Risk | Moderate (more fittings) | Lower (fewer connections) | Moderate |

| Maintenance Convenience | Moderate | High, quick solenoid replacement | Moderate |

| System Appearance | More piping, less compact | Compact and clean layout | More piping, less compact |

| Recommended Applications | Basic automation systems | Highly automated, standardized systems | General industrial control |

| Overall Cost Efficiency | Good initial cost | Best long-term value | Good initial cost |

P and PR actuators typically require external pneumatic tubing to connect a solenoid valve. While this allows flexibility, it also leads to more complex air routing. In contrast, PX actuators are designed with an integrated NAMUR interface, allowing a standard solenoid valve to be mounted directly onto the actuator without additional adapters.

This design makes PX actuators especially attractive for automated valve systems.

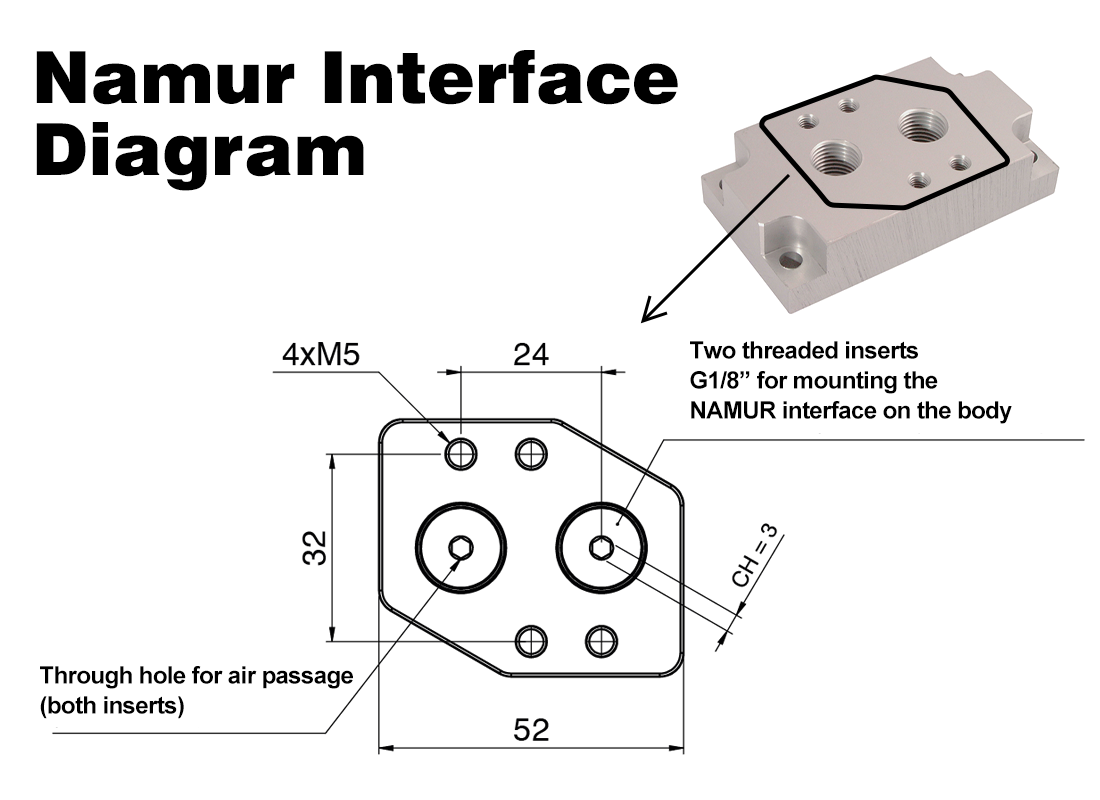

NAMUR is not a brand, but an international standard that defines the mechanical dimensions, mounting surface, thread positions, and air port locations for mounting solenoid valves on pneumatic actuators. When both the actuator and solenoid valve comply with the NAMUR standard, they can be assembled directly and securely.

For angle seat valves, an actuator with a NAMUR interface offers several practical advantages:

◆ Direct mounting of NAMUR-compliant solenoid valves

◆ Shorter air paths and faster response times

◆ Fewer external hoses and fittings, reducing leakage risk

◆ Cleaner and more compact system layout

◆ Easier installation and maintenance

These benefits become especially significant in systems with a large number of automated valves.

Among nylon actuators, PX actuators with a NAMUR interface are particularly well suited for modern automation environments. When control cabinets are equipped with standardized NAMUR solenoid valves, PX actuators can be installed quickly and consistently across the entire system.

In industries such as food and pharmaceutical processing, cleanliness and reliability are critical. Reducing external tubing simplifies cleaning procedures and improves overall system hygiene. In addition, when valves require maintenance or replacement, the NAMUR interface allows for fast removal and reinstallation of solenoid valves, minimizing downtime.

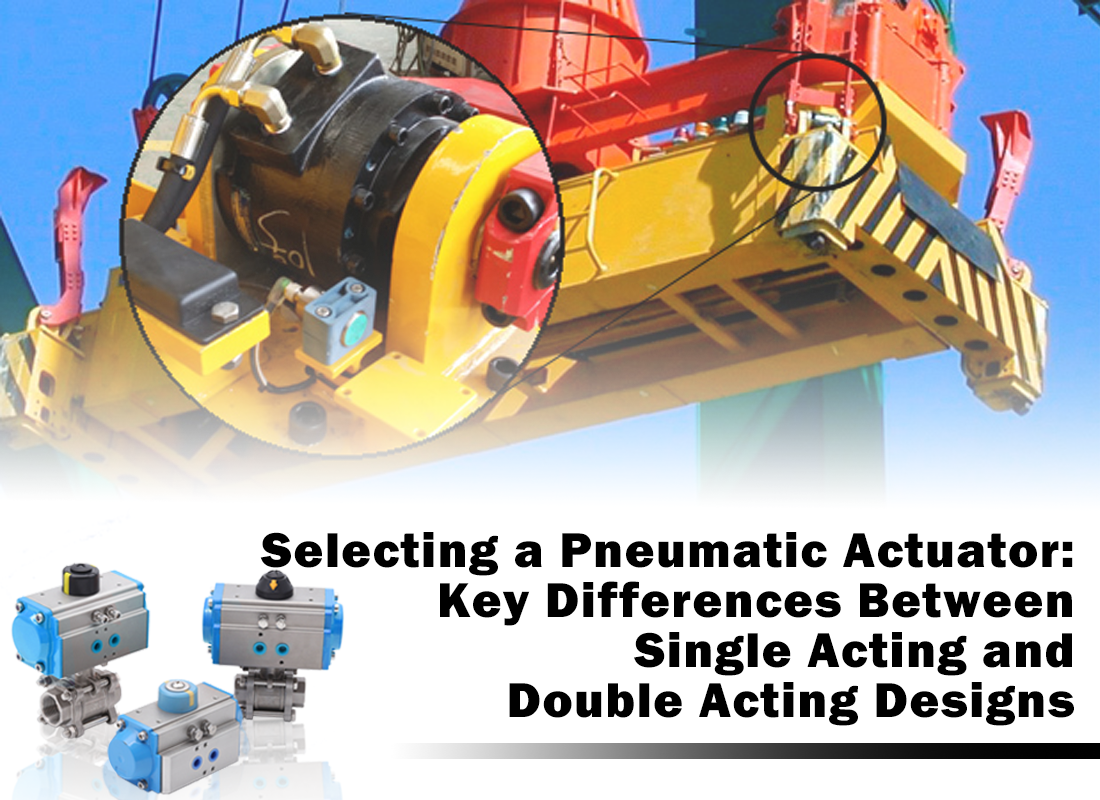

While actuator material remains an important consideration, it should not be the only factor in the selection process. Compatibility with NAMUR standards, ease of solenoid valve integration, and system-level efficiency are equally important, especially in highly automated installations.

In applications with frequent valve switching, large valve counts, or strict hygiene requirements, PX actuators with NAMUR interfaces often provide a clear advantage.

Although actuators with a NAMUR interface may have a slightly higher initial cost, they often deliver lower total system costs over time. Standardized mounting reduces engineering and installation labor, while fewer pneumatic connections mean fewer failure points and less maintenance, selecting angle seat valve actuators with NAMUR interfaces is a forward-looking decision that supports system scalability, reliability, and ease of maintenance.

If you're interested in our products, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

FOKCA ©1998-2025 All Rights Reserved Sitemap