Dec 22, 2025

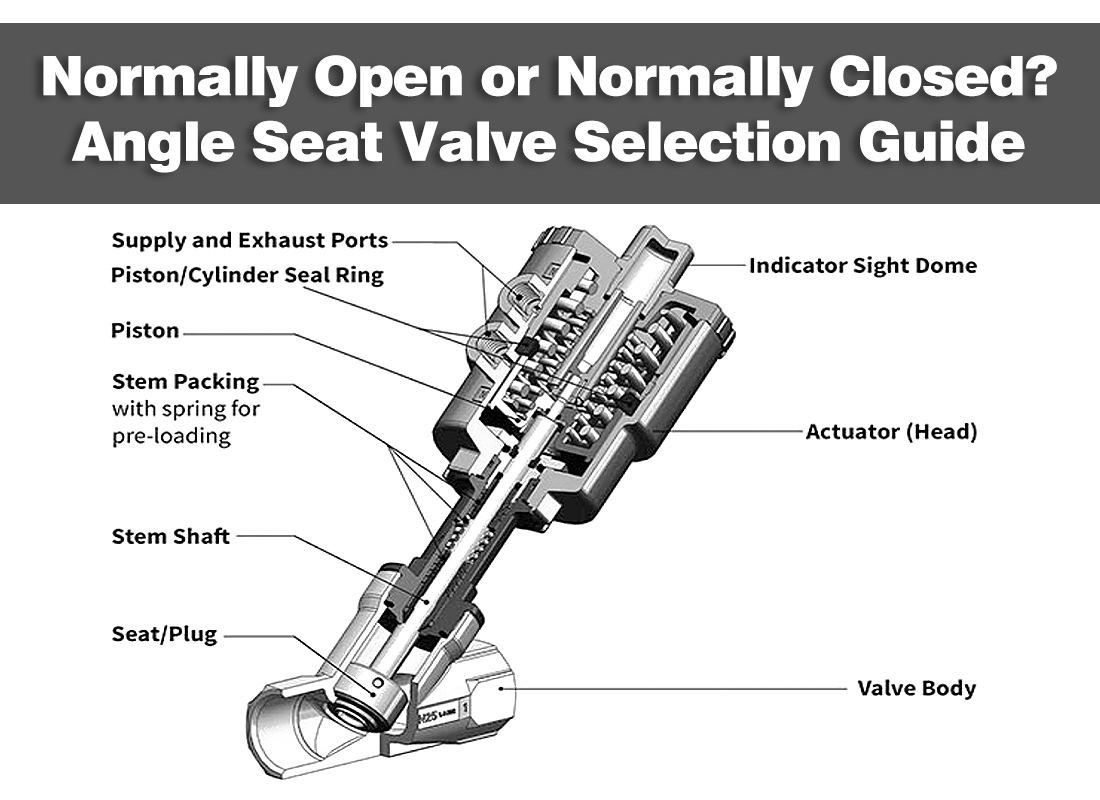

Angle seat valves are widely used in steam, water, compressed air, and various industrial fluid systems due to their high flow capacity and long service life. However, one practical question is often overlooked during installation:

Should the valve be installed with flow under the seat or over the seat?

The choice directly affects water hammer resistance, sealing performance, and long-term reliability.

An angle seat valve features an inclined seat design, with the valve plug moving axially under pneumatic actuation. Depending on how the medium enters the valve body, two installation directions are commonly used:

Flow under the seat (low inlet, high outlet)

Flow over the seat (high inlet, low outlet)

Each configuration serves a different engineering purpose and should be selected based on system conditions.

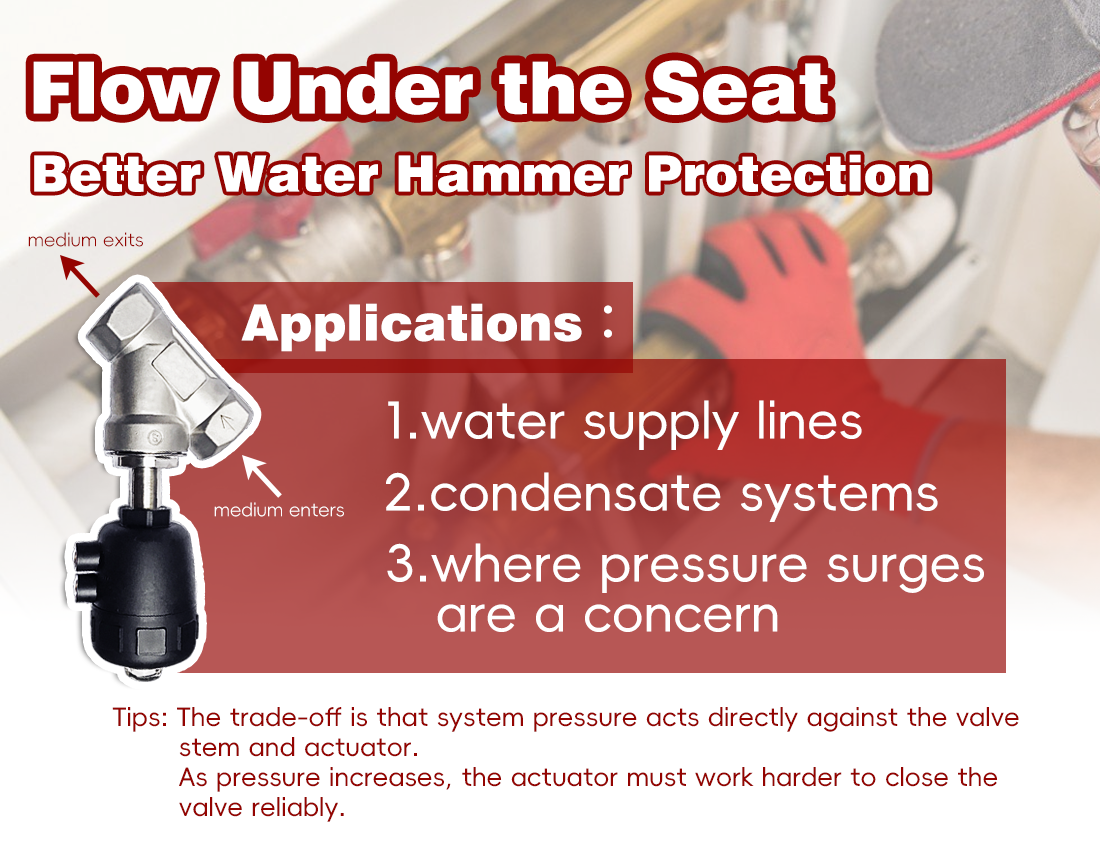

When the medium enters from below the valve seat and exits upward, it is considered flow under the seat.

This configuration helps reduce water hammer because the closing force is not directly amplified by the system pressure.

In applications such as water supply lines or condensate systems, where pressure surges are a concern, this flow direction can significantly reduce mechanical shock during valve closure.

However, the trade-off is that system pressure acts directly against the valve stem and actuator. As pressure increases, the actuator must work harder to close the valve reliably.

For this reason, flow-under-seat installation is generally recommended for low to medium pressure systems.

In most industrial installations, flow over the seat is the standard choice. In this configuration, the medium enters above the valve plug and flows toward the seat.

Here, system pressure assists valve closing rather than opposing it. This improves sealing performance and reduces stress on the actuator, making it ideal for high-pressure steam, air, or liquid applications.

The limitation is that water hammer protection is weaker compared to flow-under-seat installation. When fast closing is required, additional damping or controlled actuation may be necessary.

Most angle seat valves are marked with a flow direction arrow on the valve body. This marking reflects the manufacturer's design intent based on structural strength, sealing performance, and durability testing.

A practical guideline is:

Water hammer sensitive systems → Flow under the seat

High pressure and frequent cycling → Flow over the seat

Uncertain conditions → Follow the valve’s flow direction marking

Many valve failures—such as premature seal wear or actuator fatigue—are not caused by material defects but by incorrect flow direction.

Choosing the correct installation orientation ensures stable operation, longer service life, and reduced maintenance, especially in high-temperature and high-pressure systems.

In industrial fluid control, the installation direction of an angle seat valve is a small detail that delivers a big impact.

If you want to know more about angle seat valves, you can contact us directly.

(FK9025)

Medium Trapping in Pneumatic Ball Valve Rotation

Medium Trapping in Pneumatic Ball Valve Rotation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Influence of Insufficient Pneumatic Actuator Torque on Ball Valve Operation

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Cavity Pressure Accumulation: Causes of Abnormal Internal Pressure in Pneumatic Ball Valve

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Considerations When Using 3 Way Solenoid Valve in Vacuum Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

Switching Efficiency of 3 Way Solenoid Valve in Compressed Air Systems

You May Interest In

Nov 21, 2025 Blog

How to determine valve seat angleFOKCA ©1998-2025 All Rights Reserved Sitemap