Dec 30, 2025

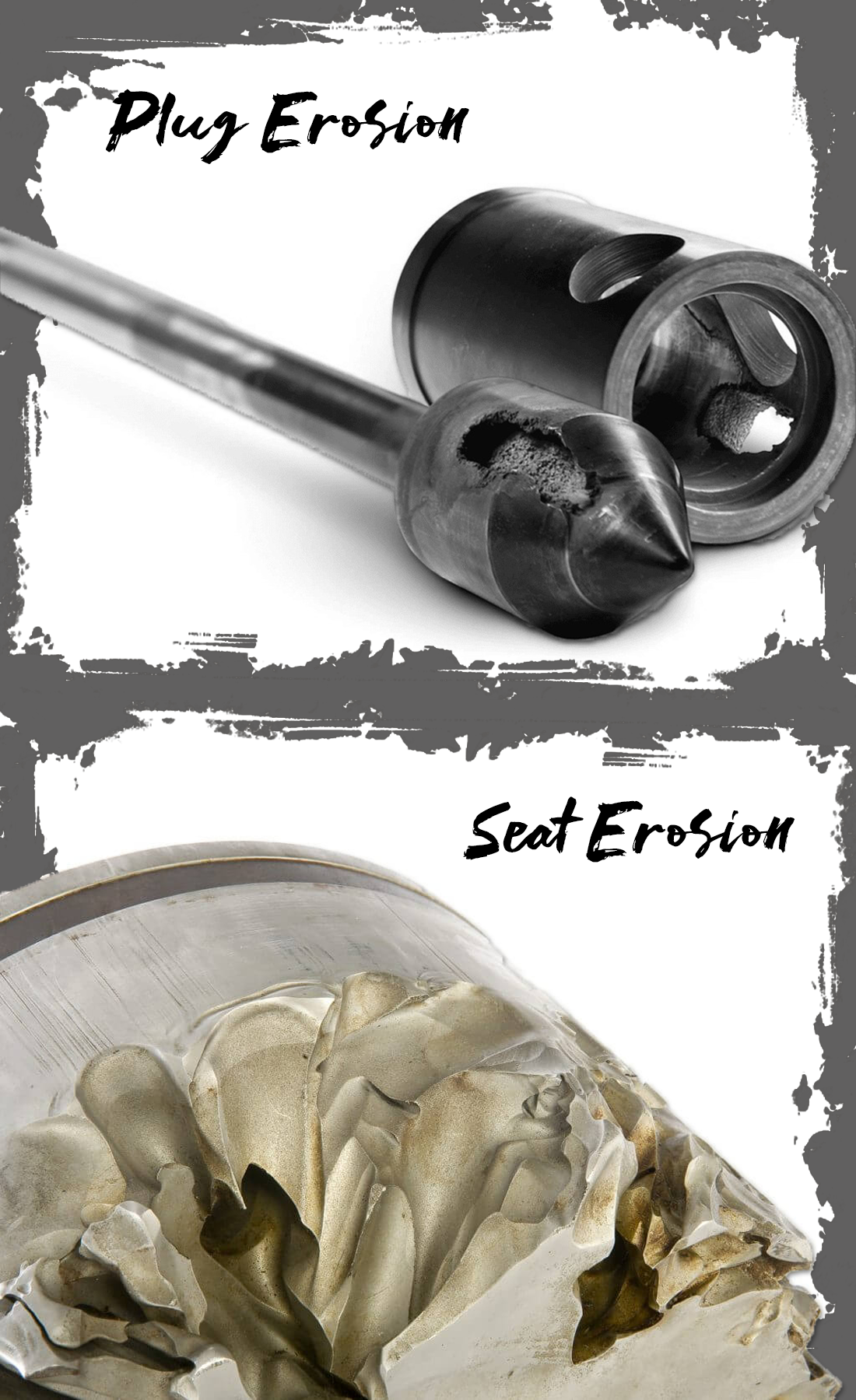

In systems handling high-velocity fluids such as steam, water, and compressed air, valve erosion is a common yet underestimated issue. Continuous exposure to fast-moving media can gradually wear down valve seats and plugs, especially in applications involving frequent cycling.

Erosion typically occurs where fluid velocity peaks—most often at the valve seat edge and the upstream surface of the valve plug. When a valve operates at partial opening, the flow is forced through a restricted area, increasing velocity and kinetic energy, which accelerates material wear.

An angle seat valve features a straight-through or gently redirected flow path that minimizes abrupt changes in flow direction. This design reduces turbulence and prevents excessive velocity concentration in localized areas. As a result, erosive forces are distributed more evenly across internal surfaces.

Unlike valves with complex internal cavities, angle seat valves allow the fluid to expand quickly after passing the seat, reducing prolonged impact on critical sealing surfaces.

The plug opening angle plays a crucial role in erosion behavior. Angle seat valves provide a relatively large effective flow area even at partial openings, helping maintain a stable velocity profile. This significantly lowers erosion intensity during high-frequency operation.

For systems requiring rapid and repeated cycling, this structural advantage translates into improved durability and consistent sealing performance.

High-cycle applications demand both fast response and long-term reliability. The axial motion of the valve plug minimizes side loads and uneven wear. Combined with erosion-resistant flow characteristics, angle seat valves are well suited for steam control, compressed air distribution, and automated process lines.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap