Jan 06, 2026

In many industrial systems, valves do not operate only in fully open or fully closed positions. Long-term operation at small openings is common during regulation phases, such as in boiler steam control, hot water circuits, and cooling water flow management. Under low-flow conditions, valves often encounter flow oscillation, unstable control, and frequent pulsation, affecting system stability and process efficiency.

The main difficulty in low-flow control is high sensitivity of flow to valve movement. When the flow is only 10–20% of full open capacity, small stem displacement or pressure fluctuations can cause noticeable flow variation. Rotating valves like ball valves or gate valves have severe nonlinearity between the flow path and the closing element at low openings, resulting in unstable control and pulsating flow, which may accelerate wear on seals and stems.

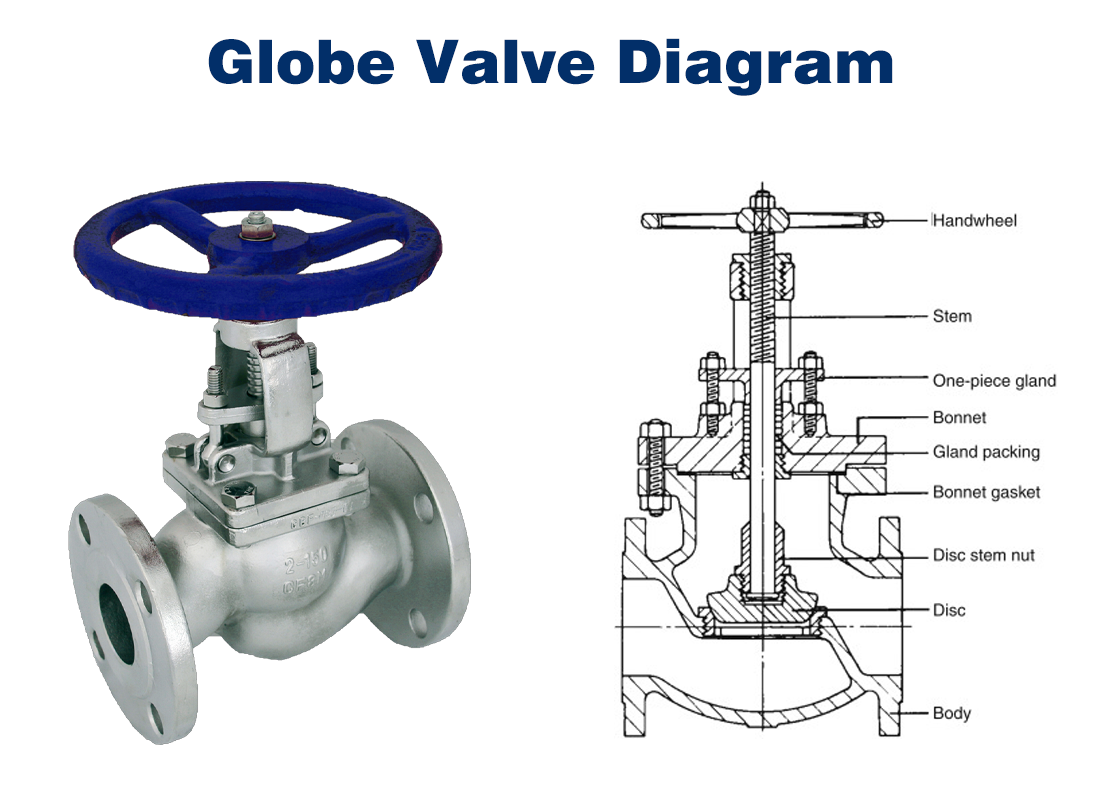

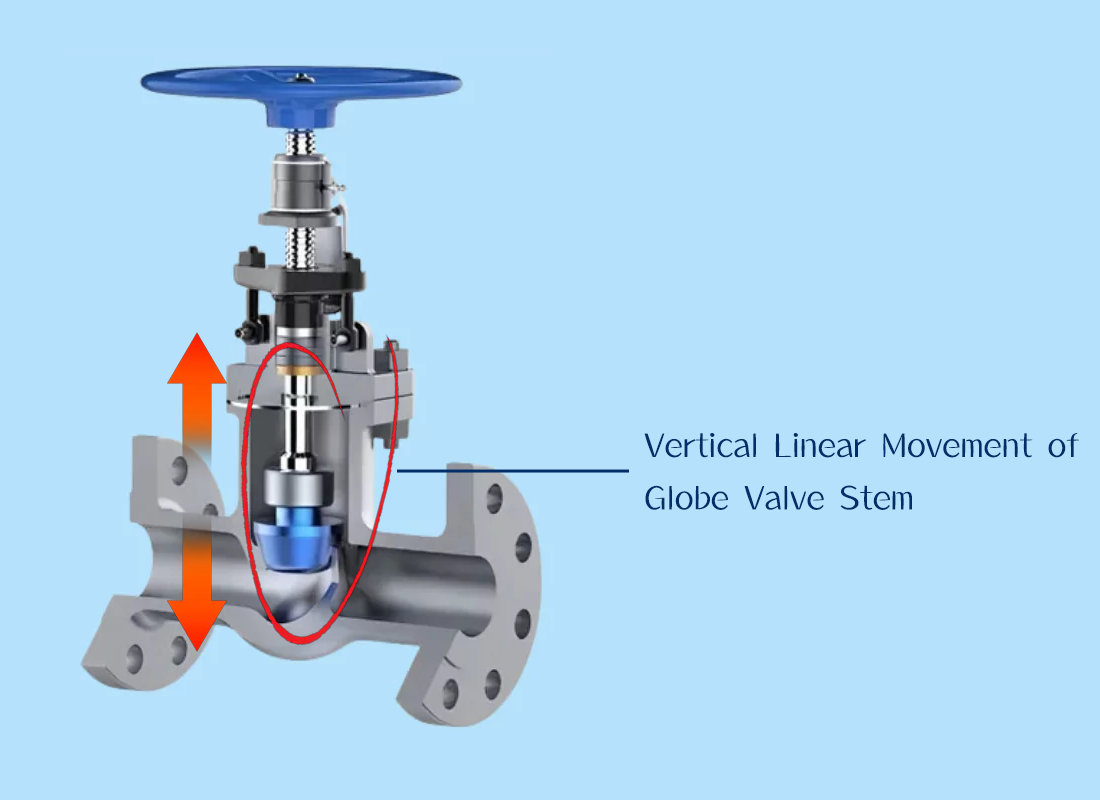

A key advantage of the globe valve is its linear stem motion, providing more predictable flow characteristics. Compared with ball or gate valves, the flow varies almost linearly with stem travel, maintaining stable flow even at low openings. This linear relationship is critical for precise control, minimizing flow oscillation and pulsation.

In boiler steam distribution systems, engineers often need to fine-tune steam flow to maintain pressure stability. Globe valves can provide smooth flow in the 10–50% opening range, while ball valves may “jump,” causing pressure or temperature fluctuations. In chemical reactors or cooling water loops, precise low-flow control affects product quality and energy efficiency. Globe valves enable stable, precise adjustment in these systems.

Combined with pneumatic or electric actuators, globe valves deliver high-precision automated control. The linear relationship between disc position and flow simplifies PID tuning, preventing overshoot or undershoot. In multi-valve or zoned control applications, globe valves maintain consistent flow rates across each control point.

For low-flow, precise control scenarios, the linear flow characteristics, straight stem design, and stable throttling of globe valves make them superior to ball and gate valves. Whether handling steam, hot water, cooling water, or chemical fluids, globe valves improve control stability, reduce pulsation risk, and extend valve service life. For industrial systems requiring accurate flow management, globe valves are an essential choice.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

FOKCA ©1998-2025 All Rights Reserved Sitemap