Jan 06, 2026

In high-pressure steam systems, valve stability matters more than simple on-off capability. Steam flow is characterized by high velocity, large density variation, and frequent pressure fluctuations, which place significant mechanical stress on valve components. This is where the globe valve demonstrates clear advantages over other valve types.

Pressure fluctuations are common in industrial steam systems due to load changes, equipment cycling, and condensate discharge. In high-pressure steam applications, these fluctuations translate into rapidly changing forces acting on valve internals. Valves that cannot handle these dynamic loads often suffer from vibration, noise, and premature wear.

Unlike liquids, steam expands rapidly as pressure drops across the valve. This expansion leads to high flow velocity and unstable force distribution, especially at throttling positions. Managing these forces effectively is critical for long-term valve reliability.

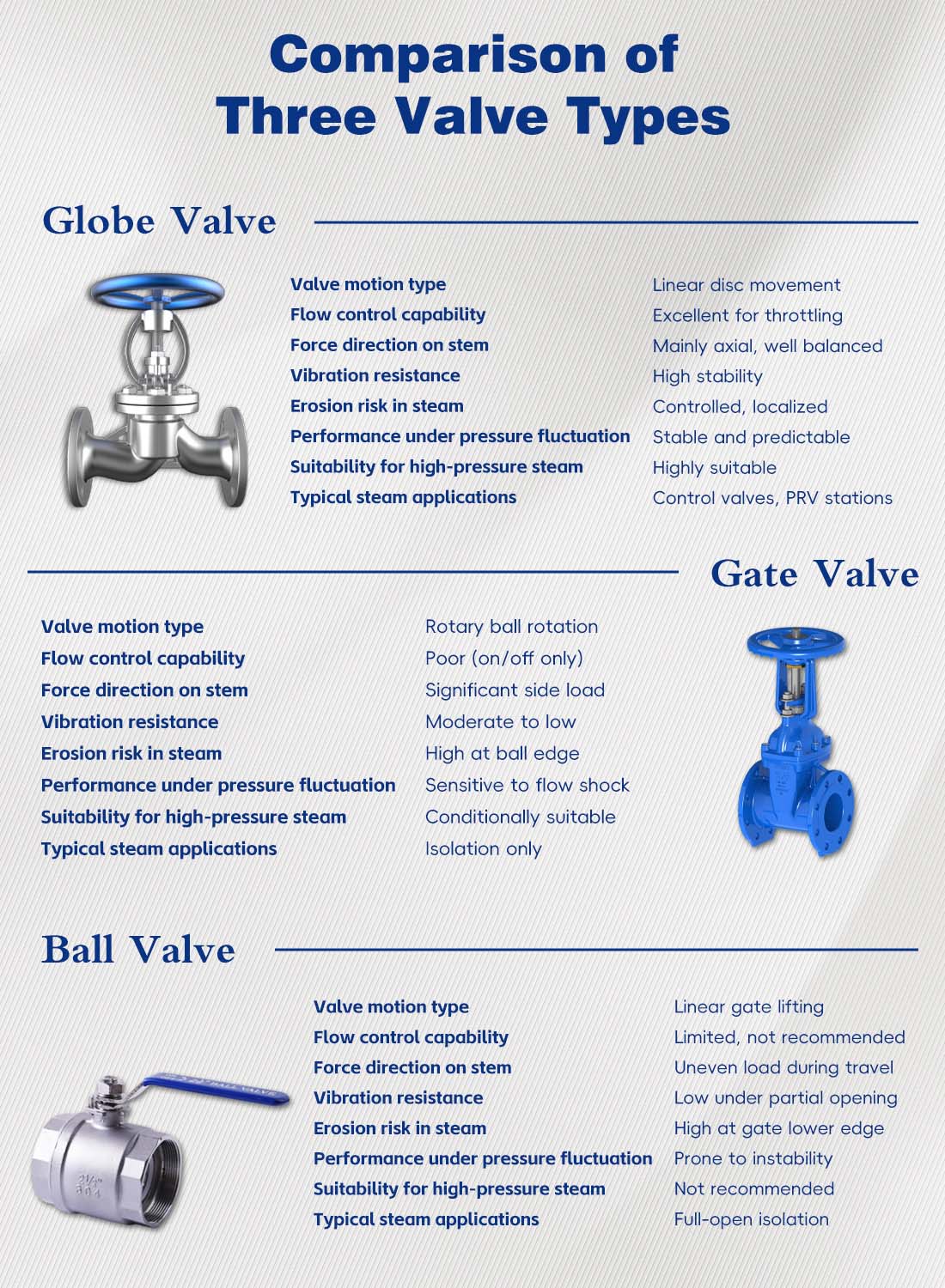

While ball valves perform well in liquid service, their rotating ball design is less suitable for high-pressure steam. During operation, the steam flow impacts the ball edge unevenly, increasing the risk of erosion, vibration, and stem loading. Over time, this can compromise sealing performance.

Gate valves are designed for full open or full close service. In steam systems, partial opening exposes the gate to high-velocity flow concentrated at the lower edge. This localized impact often results in seat damage and unstable operation, especially under frequent cycling.

A key advantage of the globe valve is its linear stem movement. The valve disc moves directly along the stem axis, ensuring that forces remain aligned and predictable. This minimizes lateral stress and reduces vibration under high-pressure steam conditions.

Globe valves are engineered with a balanced disc structure, allowing steam pressure to act more evenly during opening and closing. This balance significantly reduces dynamic instability and helps maintain consistent sealing performance even under fluctuating pressure.

Although globe valves introduce a controlled pressure drop, the erosion-prone zones are fixed and manageable. Engineers can optimize materials and surface treatments at these locations, making globe valves more durable in demanding steam control applications.

For these reasons, globe valves are widely used as steam control valves in boilers, distribution headers, and pressure-reducing stations. Their ability to manage high-pressure steam, limit vibration, and resist erosion makes them a reliable choice for long-term operation.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

FOKCA ©1998-2025 All Rights Reserved Sitemap