Jan 06, 2026

Hot oil systems are widely used in chemical processing, plastics, and thermal oil heating units, where operating temperatures often remain above 250–350°C for long periods. Unlike steam systems, hot oil has higher density and viscosity, which places continuous thermal stress on valve components. Under such conditions, globe valves are preferred for precise control, yet they are also exposed to specific high-temperature failure risks.

The primary challenge in hot oil systems is not peak temperature, but continuous thermal exposure. Repeated thermal expansion and contraction gradually affect valve body alignment, sealing performance, and mechanical tolerances. Over time, these effects can lead to performance degradation rather than sudden failure.

Engineers often notice increased operating torque or reduced control accuracy before visible leakage occurs.

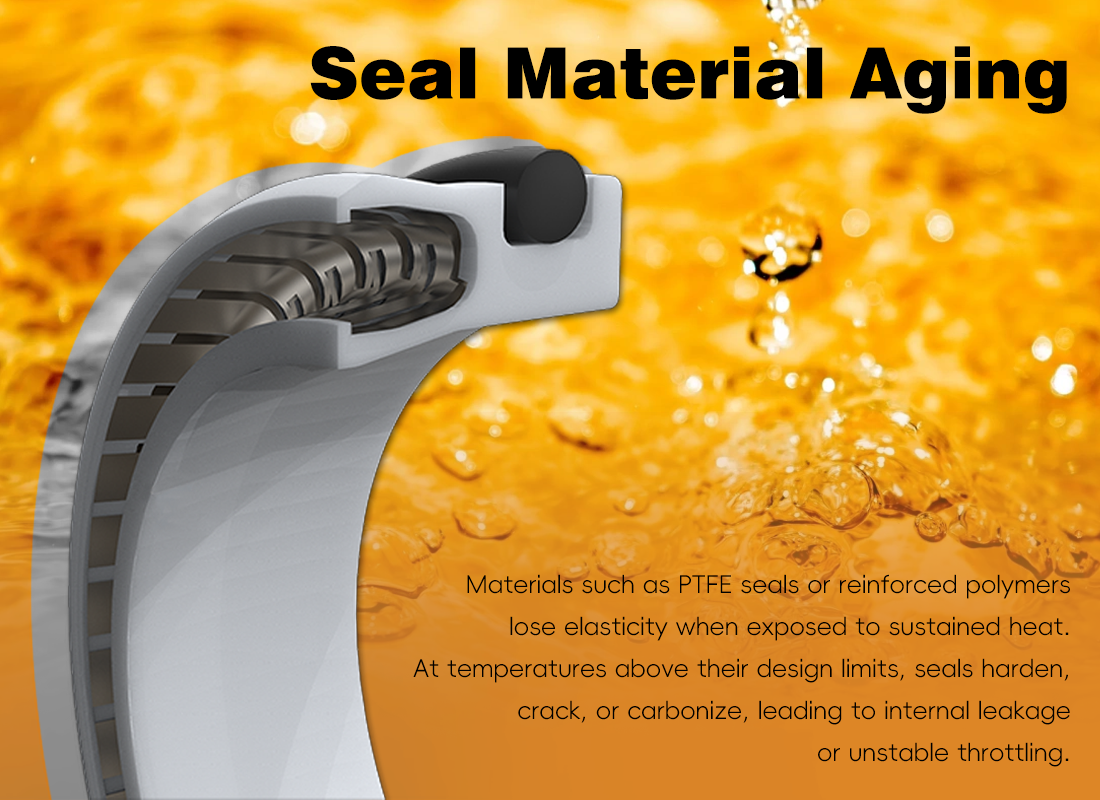

Seal degradation is one of the most common failure initiators in high-temperature globe valves. Materials such as PTFE seals or reinforced polymers lose elasticity when exposed to sustained heat. At temperatures above their design limits, seals harden, crack, or carbonize, leading to internal leakage or unstable throttling.

In many hot oil installations, sealing issues emerge after one to two years of continuous operation, even when the valve body remains structurally intact.

Thermal expansion of the valve seat presents another major risk. When the seat and body expand at different rates, excessive contact pressure can develop between the disc and seat. This increases operating torque and may cause disc sticking or accelerated wear.

Under partial-open conditions, localized heating further intensifies thermal stress, especially in flow control applications.

The valve stem plays a critical role in maintaining linear control. In high-temperature environments, inadequate material selection or surface treatment can result in stem oxidation or thermal bending. Increased friction between the stem and packing compromises the valve’s response accuracy.

This often appears as delayed positioning or uneven movement during regulation.

Packing systems are especially vulnerable in hot oil service. Conventional packing materials lose preload force over time, resulting in leakage along the stem. Graphite packing or high-temperature packing sets are commonly used to improve sealing reliability and allow in-service adjustment.

Reducing failure risk begins with proper valve design. Metal-to-metal seats, high-temperature alloys, and optimized stem finishes significantly enhance durability. From an operational standpoint, avoiding continuous minimal opening conditions helps reduce erosion and thermal concentration.

Routine monitoring of operating torque and control response provides early indicators of internal wear, allowing maintenance before leakage or shutdown occurs.

Despite these challenges, globe valves remain widely used in hot oil systems due to their balanced disc force and linear stem movement. Compared with ball valves and gate valves, globe valves offer better control stability and lower vibration under high-temperature conditions.

With appropriate material selection and maintenance planning, globe valves can deliver reliable long-term performance even in demanding hot oil applications.

(FK9025)

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

Overlooked Environmental Factors Affecting Solenoid Valves in Outdoor Applications

You May Interest In

Dec 23, 2025 Blog

How Actuator Size Affects Valve Performance

FOKCA ©1998-2025 All Rights Reserved Sitemap