Jan 04, 2026

In industries such as food processing, pharmaceuticals, steam control, and automated production lines, angle seat valves are often exposed to high-cycle operation. In these conditions, valves may open and close thousands of times per day. Compared to static or low-frequency applications, high-cycle use significantly increases mechanical wear and demands closer maintenance attention.

Each valve cycle involves contact between the valve plug and seat, as well as repeated force from the pneumatic actuator. Under high switching frequency, even minor friction and impact forces accumulate rapidly.

When combined with steam, compressed air, or high flow velocity, these repeated movements accelerate wear on sealing and guiding components, gradually reducing valve performance.

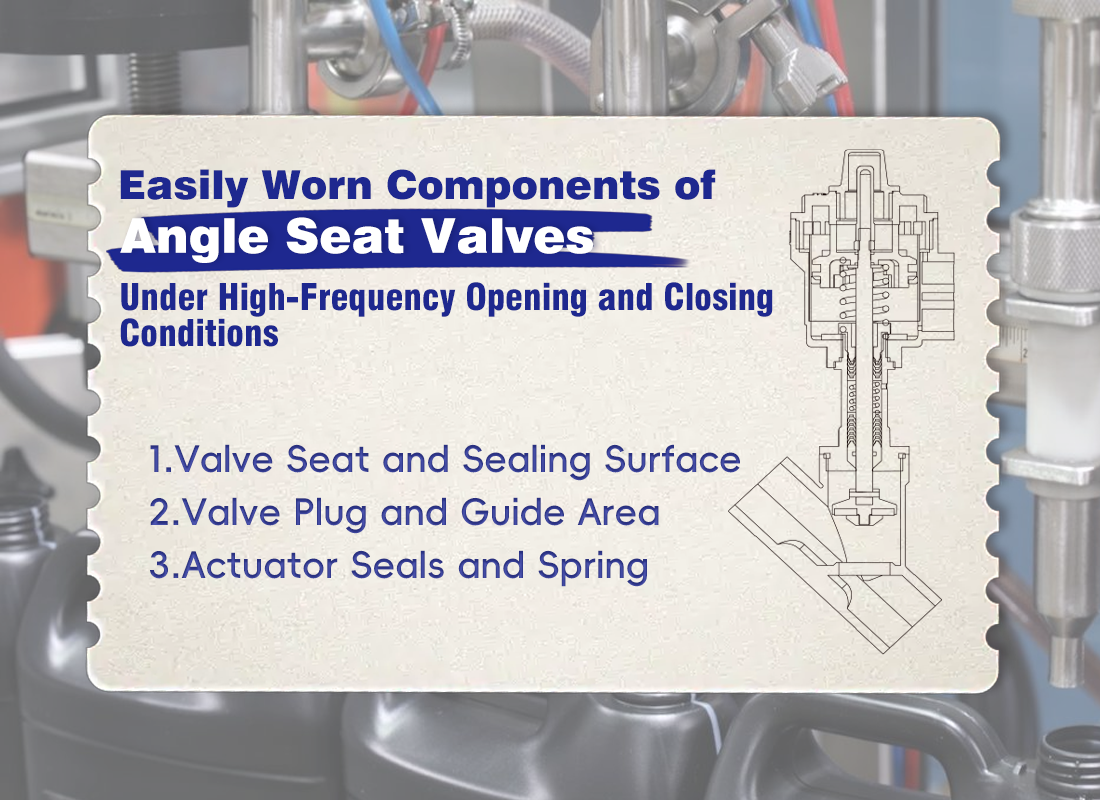

The valve seat experiences repeated compression during every closing cycle. Over time, this leads to surface wear, especially in applications with condensate or particles, resulting in internal leakage.

Angle seat valves rely on linear motion. In high-cycle service, wear in the guide area can cause inconsistent movement or increased friction, affecting opening and closing speed.

Inside the pneumatic actuator, seals and return springs are constantly stressed. Seal aging or spring fatigue may cause slower response or incomplete stroke.

High-cycle valve failure rarely happens without warning. Common early indicators include:

◆ Changes in opening or closing speed

◆ Increased air consumption

◆ Minor leakage after closing

◆ Unusual noise or vibration during operation

Identifying these signs early allows maintenance before performance drops significantly.

For high-frequency applications, proactive maintenance is more effective than reactive repair:

◆ Track valve cycle counts instead of only operating hours

◆ Inspect sealing surfaces during scheduled shutdowns

◆ Monitor actuator responsiveness and repeatability

◆ Avoid running actuators continuously at maximum load

These measures help extend valve service life and reduce unexpected downtime.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap