Dec 31, 2025

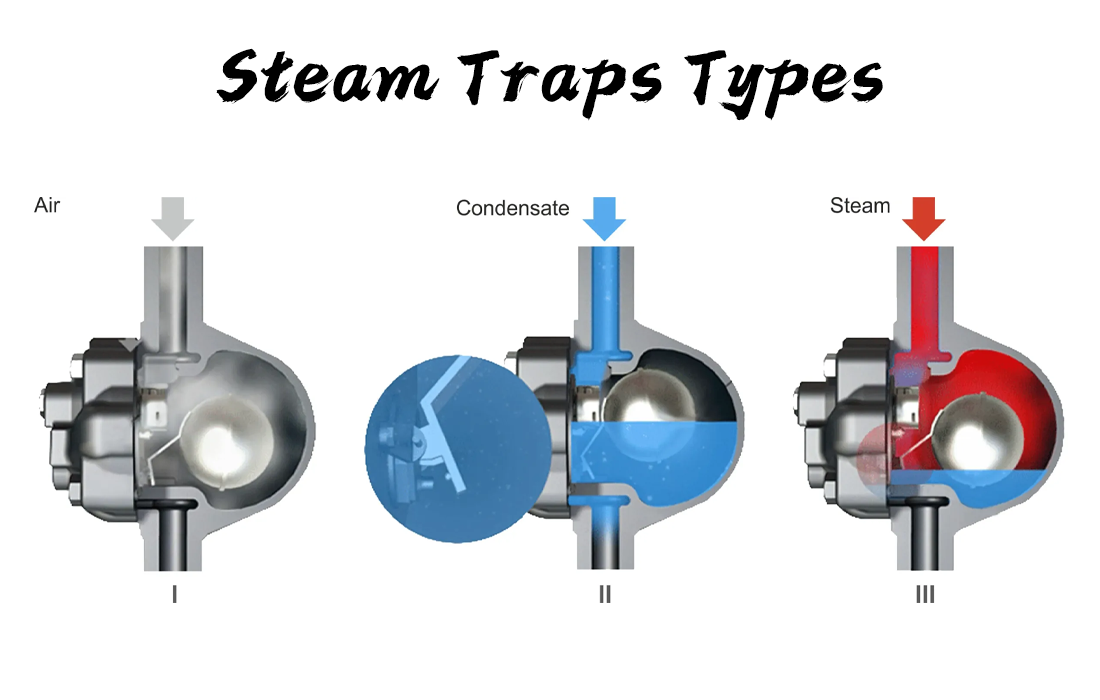

In steam systems, condensate formation is unavoidable. During startup, shutdown, or load changes, part of the steam inevitably condenses into liquid water. If not properly drained, this condensate can significantly shorten valve service life, particularly in angle seat valves used for frequent on-off control.

Unlike steam, liquid water has much higher density and inertia. When high-speed steam carries condensate through a valve, water droplets or slugs strike the valve seat and sealing surfaces with considerable force. This intermittent impact is far more damaging than steady fluid flow.

In steam service, valve seats operate at elevated temperatures. When cooler condensate contacts these hot surfaces, thermal shock occurs alongside mechanical impact. Over time, this combination causes micro-cracks, surface deformation, and gradual loss of sealing integrity.

As sealing surfaces become uneven, the valve can no longer maintain uniform contact pressure, leading to leakage and reduced shut-off performance.

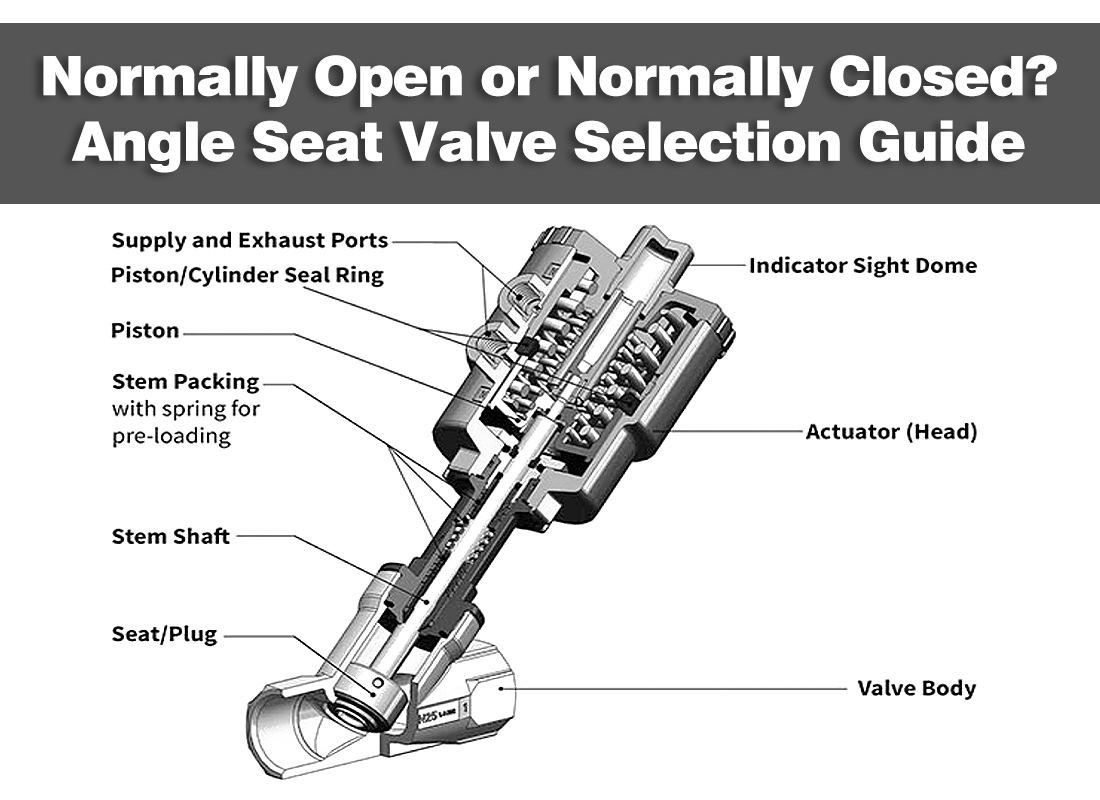

Angle seat valves in steam systems are typically installed with the stem upright and flow entering from below the seat. This orientation helps prevent condensate from collecting near the sealing area and allows steam to pass smoothly through the valve body.

Incorrect installation can trap condensate inside the valve chamber, exposing the seat and seals to repeated water impact during every cycle.

Effective drainage is essential for protecting angle seat valves. Installing steam traps, maintaining proper pipe slope, and positioning valves downstream of drainage points significantly reduce condensate entering the valve.

Angle seat valves perform best when installed in well-drained steam branches, rather than in sections where condensate accumulates.

The straight-through flow path and vertical plug movement of angle seat valves help distribute flow energy more evenly. When combined with proper installation and drainage, these features minimize localized damage and extend service life in demanding steam applications.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 18, 2025 Blog

How Does a Shuttle Valve Work in Pneumatic Systems?

FOKCA ©1998-2025 All Rights Reserved Sitemap