Jan 09, 2026

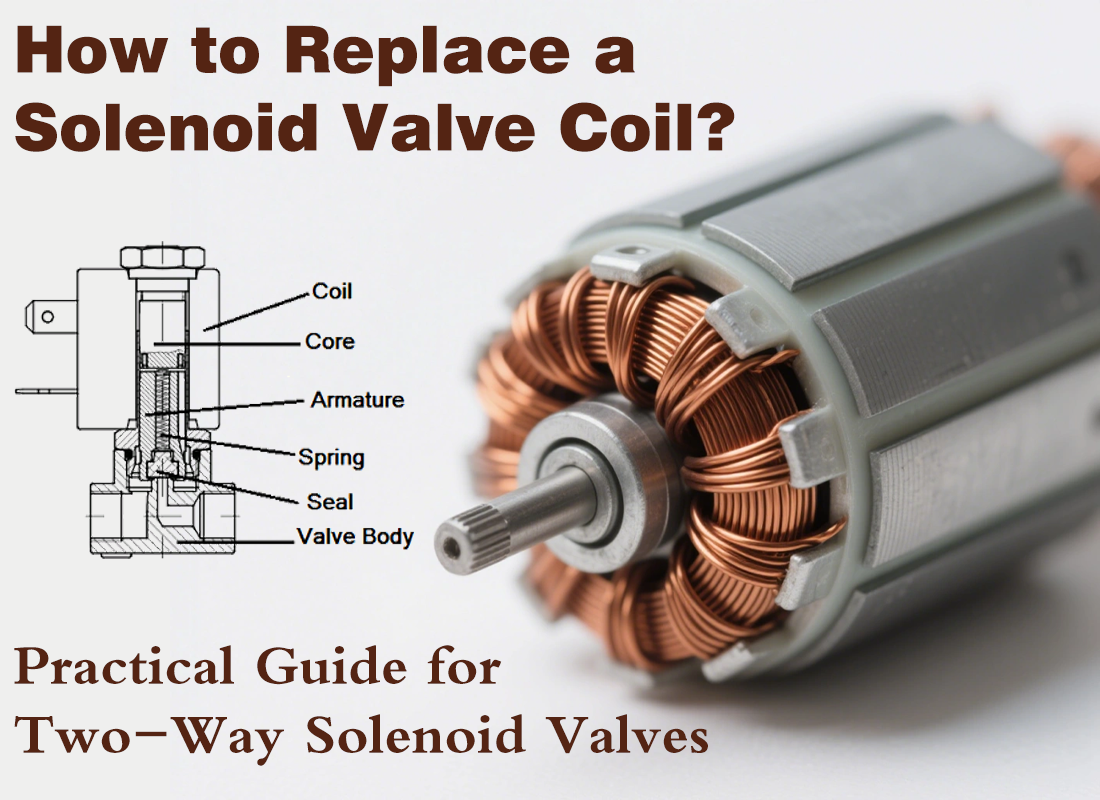

In automation systems, the solenoid coil of a two-way solenoid valve is one of the most failure-prone components. Many technicians replace the coil immediately when a valve stops working, but experience shows that not every malfunction is caused by a failed coil. Proper diagnosis can save time, cost, and unnecessary downtime.

A solenoid coil generates a magnetic field when energized, and long-term exposure to voltage, heat, and environmental factors makes it a typical wear component.

Common causes of failure include unstable voltage, poor heat dissipation during continuous operation, moisture ingress, and thermal fatigue caused by frequent switching.

Once the internal insulation degrades, the coil may short-circuit or break internally, resulting in valve failure.

Before replacing the coil, it is important to verify whether the fault truly lies in the coil. Many apparent coil failures are actually caused by external issues.

Start by checking the power supply voltage and ensuring it matches the coil rating. Inspect wiring connections for looseness or oxidation. If the voltage is correct but the valve does not actuate, measure the coil resistance with a multimeter. An open circuit or abnormal resistance usually indicates a damaged coil.

Mechanical issues should also be considered. Damaged seals, stuck valve cores, or contamination inside the valve body can prevent operation even when the coil is functioning properly.

Many two-way solenoid valves are equipped with a manual override button. If the valve opens and closes normally using manual control but fails under electrical control, the problem is likely related to the coil or electrical circuit.

If neither manual nor electrical operation works, the issue is more likely within the valve body. This simple distinction helps prevent replacing coils unnecessarily.

Once the coil is confirmed faulty, replacement is straightforward but must follow proper procedures. Always disconnect the power supply completely before removal.

Remove the damaged coil according to its mounting design, such as a retaining nut or clip. Inspect the armature tube and clean any dirt or corrosion before installing the new coil.

Ensure the replacement coil matches the original voltage rating, power consumption, and duty cycle. Slide the coil vertically onto the armature tube, fix it securely, and avoid misalignment that could cause vibration or overheating.

Although generic replacement coils may appear compatible, differences in winding design, insulation class, and heat dissipation can lead to insufficient magnetic force or excessive temperature rise.

Original manufacturer solenoid coils are designed to match the valve’s magnetic circuit, ensuring stable operation and controlled temperature rise—especially important for continuous-duty or high-frequency applications.

After installation, perform several on-off tests and listen for abnormal noise. During initial operation, monitor coil temperature to ensure it remains within normal limits.

In critical systems, engineers often record coil replacement intervals to establish preventive maintenance schedules, helping identify potential electrical issues before failure occurs.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Dec 31, 2025 Blog

Pneumatic Solenoid Valve Manual Button Explained

FOKCA ©1998-2025 All Rights Reserved Sitemap