Jan 09, 2026

In chemical processing systems, valve leakage is rarely a sudden failure. In many real-world cases, globe valve leakage is caused by improper material selection rather than structural design flaws. Once the valve body or sealing materials cannot withstand long-term corrosion, even a well-designed valve will eventually fail.

In pipelines handling acidic fluids, chlorides, or mixed solvents, early signs may include minor external leakage or increased operating torque. Over time, corrosion attacks the seat surface and packing area, leading to incomplete shut-off or sudden leakage.

These failures often occur after months or years of operation, making replacement costly and disruptive. This is why material selection is critical in chemical applications.

Chemical media often involve multiple corrosion mechanisms, including chemical corrosion, crevice corrosion, and stress corrosion cracking. Under elevated temperature and pressure, these mechanisms can accelerate material degradation.

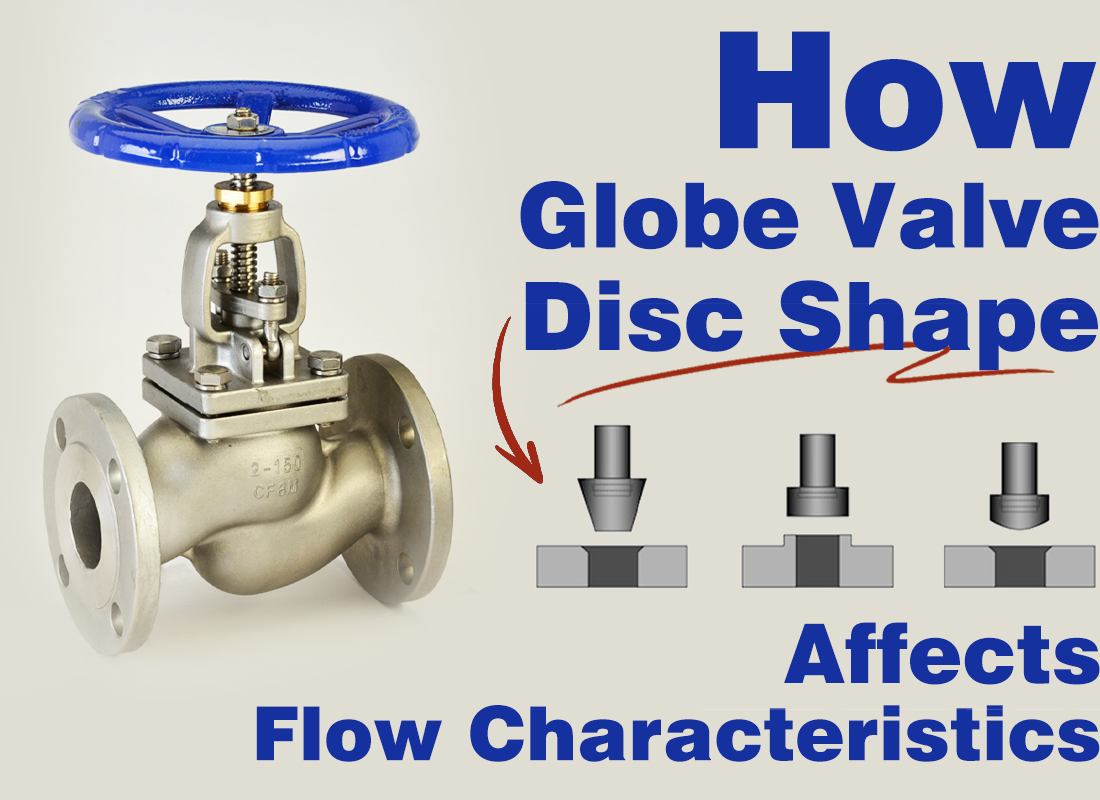

For globe valves, the seat-to-disc contact area and the stem packing zone are usually the first regions affected. If material resistance is insufficient, sealing performance deteriorates rapidly.

In many projects, stainless steel globe valves are considered a safe default. However, 304 stainless steel may suffer pitting corrosion in chloride-rich or acidic environments.

316 and 316L stainless steel, with higher molybdenum content, offer better resistance to chlorides and aggressive chemicals. The low-carbon grade 316L is especially suitable for welded systems and high-temperature operation, reducing the risk of intergranular corrosion.

For extremely aggressive media, duplex stainless steel or special alloys may be required.

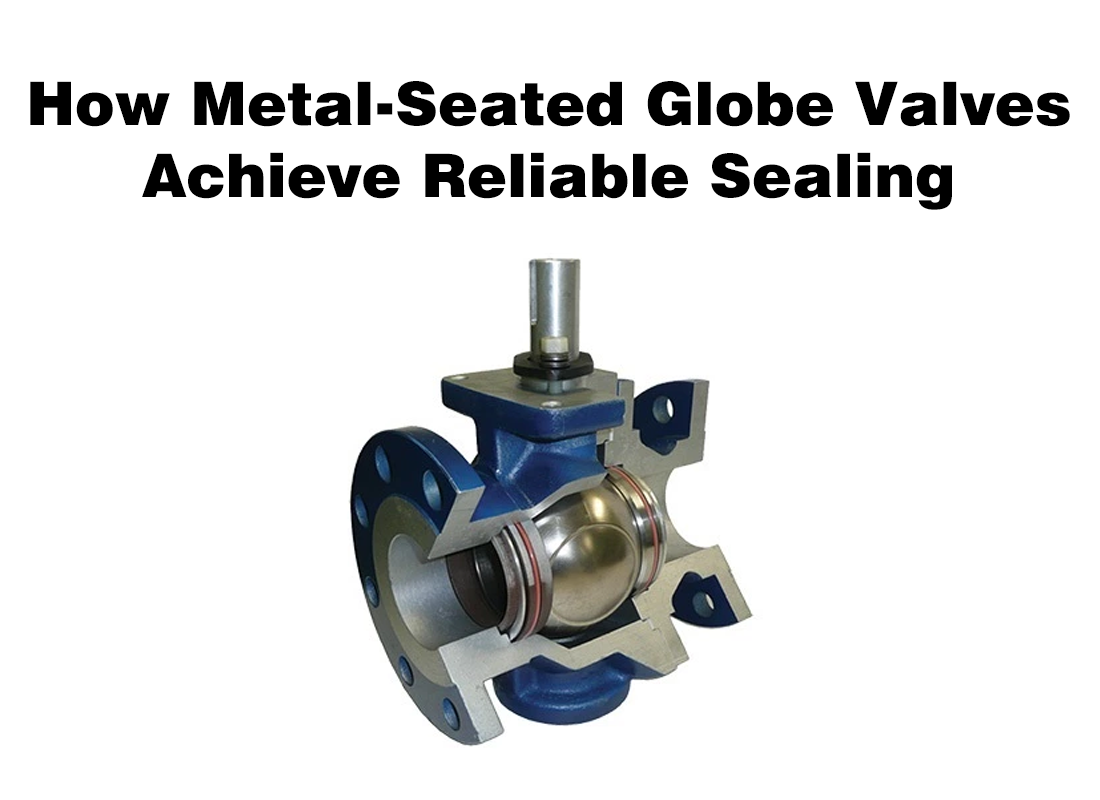

In many corrosion-related failures, the sealing system fails before the valve body. Materials such as PTFE, reinforced PTFE, and metal-seated designs behave very differently in chemical environments.

Soft seals provide excellent initial sealing but may swell, harden, or degrade under high temperature or solvent exposure. Metal-seated globe valves, although requiring higher operating force, maintain structural stability under corrosive and high-temperature conditions.

Seal material selection must match the chemical composition, temperature range, and operating frequency of the system.

The performance advantages of a globe valve—stable throttling and reliable sealing—depend entirely on material durability. Once corrosion compromises the material, no flow path design can prevent leakage.

Structural mismatches usually become apparent during commissioning, while material-related issues develop slowly and often lead to irreversible damage.

When selecting globe valves for corrosive chemical service, engineers typically prioritize material compatibility based on media composition, temperature, pressure, and cleaning processes.

Using higher-grade materials at critical points while optimizing cost on secondary lines is a common and effective engineering strategy, offering better long-term reliability than uniform cost-driven selection.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

Jan 08, 2026 Blog

Why Globe Valves Cannot Fully Replace Ball Valves

FOKCA ©1998-2025 All Rights Reserved Sitemap