Jan 04, 2026

In automated production lines, engineers rarely focus only on whether a valve can open or close. What really matters is repeatability, response stability, and long-term reliability. In many industrial applications involving steam, water, or compressed air, angle seat valves serve as the final control element. However, their actual operating behavior is largely determined by the solenoid valve installed upstream.

Angle seat valves and solenoid valves do not simply work “side by side.” They follow a clear division of responsibilities within the control system, and understanding this coordination helps engineers avoid slow response, misoperation, or premature wear.

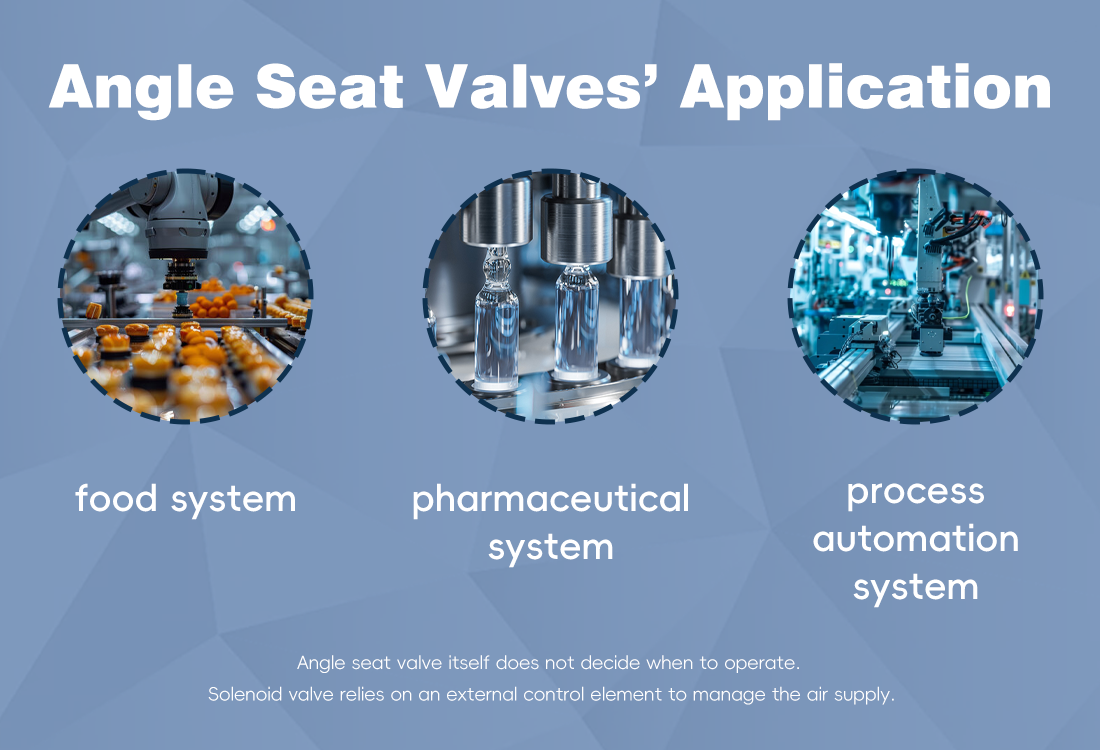

An angle seat valve is essentially a pneumatic actuator-driven valve. It does not process electrical signals directly. Instead, compressed air drives a piston or diaphragm, moving the valve stem in a linear motion to open or close the flow path. This design allows angle seat valves to handle large flow rates, pressure fluctuations, and high switching frequency, making them common in food, pharmaceutical, and process automation systems.

However, the valve itself does not decide when to operate. It relies on an external control element to manage the air supply.

In most automated systems, PLCs and controllers output electrical signals, not pneumatic pressure. A solenoid valve converts these electrical signals into controlled air flow. By energizing or de-energizing the coil, the solenoid valve directs compressed air into or out of the actuator chamber of the angle seat valve.

From a system perspective, the solenoid valve acts as the control interface, while the angle seat valve performs the mechanical action. The solenoid valve determines when air is supplied or exhausted, and the angle seat valve translates that air pressure into motion.

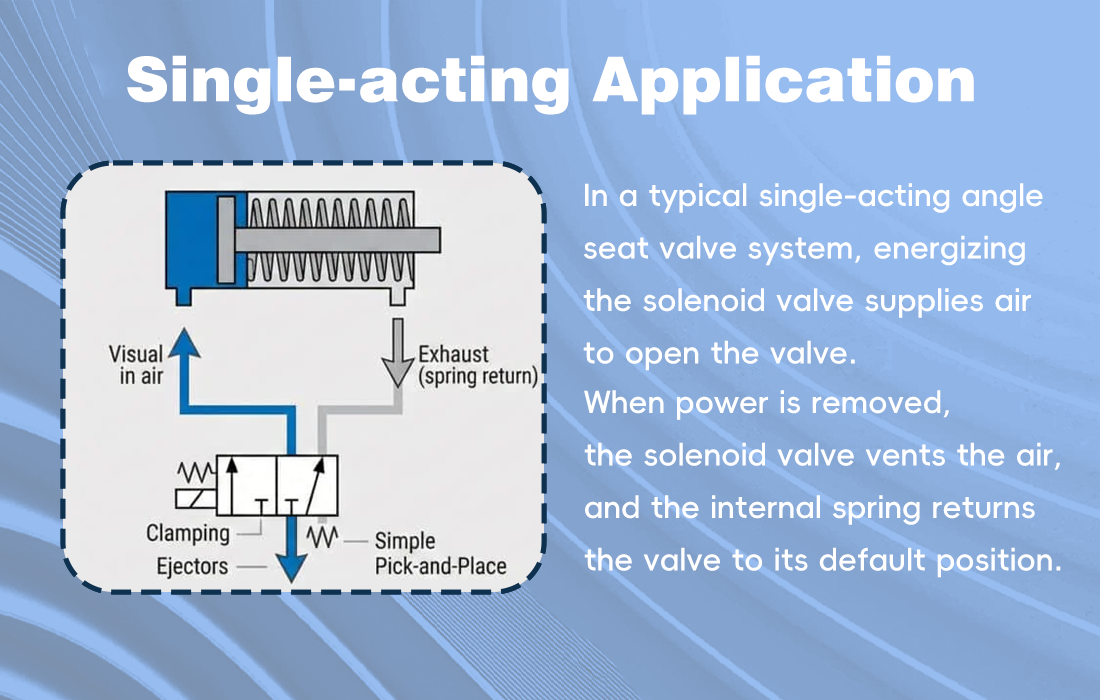

In a typical single-acting angle seat valve system, energizing the solenoid valve supplies air to open the valve. When power is removed, the solenoid valve vents the air, and the internal spring returns the valve to its default position. In this setup, the switching speed and sealing performance of the solenoid valve directly influence the response of the angle seat valve.

Any internal leakage or delayed response in the solenoid valve can result in incomplete opening, unstable positioning, or slower cycle times. This is why fast-response solenoid valves with reliable sealing are commonly paired with angle seat valves in automated production lines.

Separating control and execution functions offers significant advantages. Adjustments to control logic can be made by modifying the solenoid valve or electrical system, without altering the main process valve. This makes the system more flexible and easier to maintain.

Fault diagnosis also becomes clearer. Electrical issues, pneumatic control issues, and valve sealing problems are easier to isolate, which is critical for continuous production environments where downtime must be minimized.

In food and pharmaceutical processing lines, angle seat valves are often used for steam or cleaning media, operating at a fixed rhythm and high frequency. In such cases, the reliability of the solenoid valve directly affects process timing. Coil overheating or unstable switching in the solenoid valve can translate into inconsistent valve movement.

Experienced engineers therefore evaluate angle seat valves and solenoid valves as a combined system, not as individual components. The angle seat valve handles the process conditions, while the solenoid valve defines the control rhythm. Together, they form a stable and efficient automation solution.

(FK9025)

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

One-Way Flow Design: Typical Applications of 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

The Impact of Flow Path Reduction on Pressure Drop in 2 Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Pressure Differential: The Key Factor Behind Stable Operation of 2-Way Solenoid Valves

Control Considerations for Solenoid Valves Used in Parallel Systems

Control Considerations for Solenoid Valves Used in Parallel Systems

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

The Impact of Voltage Fluctuation on Solenoid Valve Stability:Why Insufficient Voltage Causes Incomplete Actuation

You May Interest In

FOKCA ©1998-2025 All Rights Reserved Sitemap